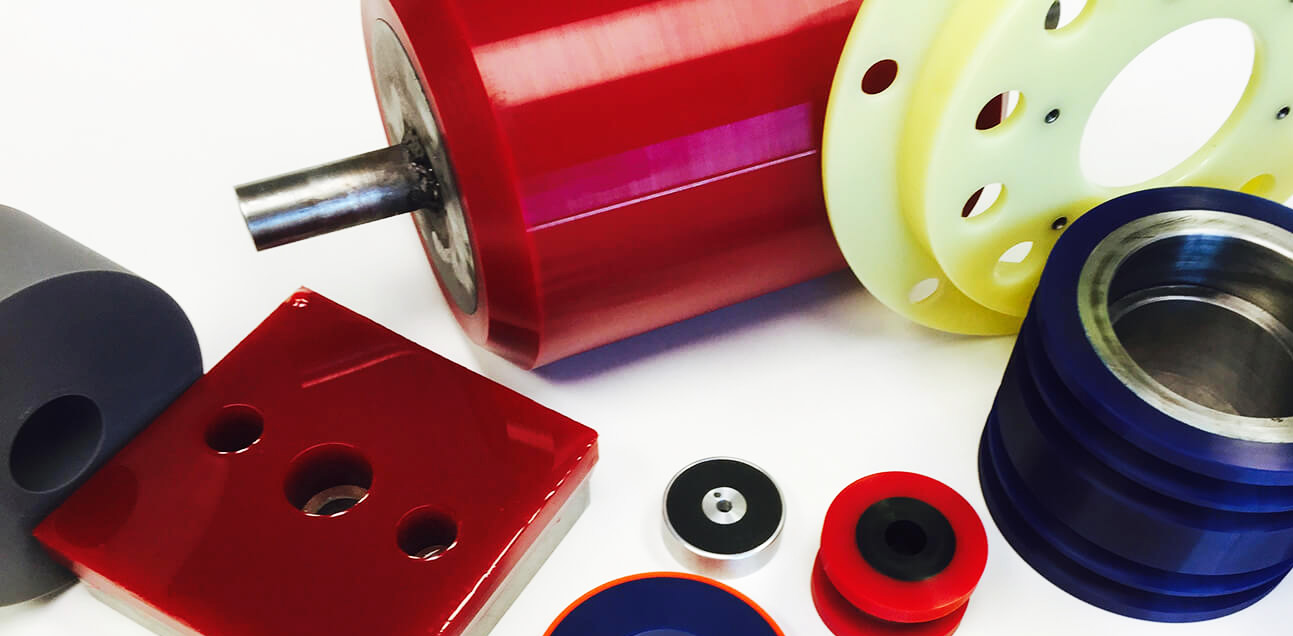

As you can see, there is a remarkable range of urethane physical properties to choose from allowing urethane to be used across a wide variety of applications and industries.

For more information on the physical properties of urethane, be sure to check out the urethane technical brief or contact PSI today.