Cast Polyurethane Liners

The Best Solution for High Wear Solutions

Polyurethane liners are primarily used to solve wear issues related to the bulk transport or movement of materials. Simply put, they protect equipment from wear and tear. Like other urethane product applications, urethane liners help prevent machinery maintenance and downtime, offer long-lasting protection, and can be easily customized to meet the specific needs of your industry.

Whether you need a drop-in liner, bolt-in liner, or a liner that satisfies FDA requirements, PSI’s urethane liners can be customized to fit your application and offer superior performance to help reduce equipment downtime and overall material costs.

Not all urethane liners are bonded. They can also be manufactured as drop-in liners or sheet material to meet the needs of your specific application.

Available Custom Urethane Liner Specs

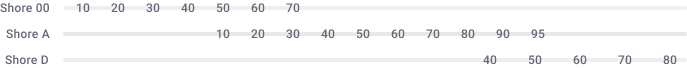

Durometer Hardness

- 20 Shore A to 90 Shore A

- 50 Shore D to 70 Shore D

Here is a list of our standard durometer specifications and our technical brief, to assist you with choosing the correct material.

Durometer Reference Calculator

For reference, this hardness is as soft as a Gel Shoe Insole

For reference, this hardness is as soft as a Rubber Band

For reference, this hardness is as soft as a Pencil Eraser

For reference, this hardness is as soft as a Tire Tread

For reference, this hardness is as soft as a Shopping Cart Wheel

For reference, this hardness is as soft as a Hard Hat

Application Specific Formulations

- FDA Dry Food Approved 40A to 85A

- Static Dissipative material is available in 40A to 85A (other durometers may be available upon request)

Benefits of Urethane Liners

Urethane liners are often used to protect metal hoppers and chutes from abrasive compounds, and are especially beneficial inside concrete mixers and hoppers. Their superior performance in viscous situations makes sustained use, cleanup, and care easy.

They can be bonded to existing equipment to give it new life, and are oftentimes utilized in fan and pump housings, cyclones, semi-trailers, screen frames, steel hoppers, dump trucks, concrete hoppers, tanks, grain bowls, pipes, potable water systems, and centrifugal finishing machines.

Polyurethane Liner Applications

Urethane liners can bring new life to your operation. These abrasion resistant urethane linings protect equipment from prolonged wear and urethane, in particular, offer the best abrasion resistance the industry has to offer. Urethane is also chemical resistant and can be bonded to metal to provide additional stiffness. It is great for the transport or movement of sticky materials. With urethane, the dirt or sludge rolls off easily.

Urethane liners are preferred in many transport situations. Urethane is most often selected as the preferred lining because it:

- Helps minimize impact and sliding abrasion damage in abrasive situations

- Resists corrosion

- Resists many chemicals, including oil, fuel, and grease

- Helps minimize noise, sound dampening

- Has a low coefficient of friction

- Has a high tear strength

- Resists impingement

Call PSI for a Custom Quote

Call one of our experienced urethane professionals at (800) 888-5156 for design assistance and to get help selecting the right lining for your equipment and processes. You can also conveniently request a quote for any size project online, at any time.

Industries Utilizing Urethane Liners

Many industries rely on urethane liners for their needs, including:

Food Processing

PSI manufactures FDA approved urethane products for food processing applications.…

Metal Forming

PSI Urethanes is a leading manufacturer of cast urethane for metal forming press…

Military

We manufacture custom molded parts, polyurethane sheets, and bond to metal for the…

Die Cutting

Our quality and accuracy in keeping close tolerances make our company sought out…

Fluid Cell Remold

For industries that depend on highly complex parts to keep their equipment functioning,…

OEM's

Original Equipment Manufacturers (OEMs) utilize PSI Urethanes’ manufacturing expertise…

Marine

PSI Urethanes is a leading manufacturer of cast and molded urethane for the marine…

Process Automation

From rollers and bumpers to assembly systems and material handling, urethane is a…

Automotive

PSI Urethanes is a leading manufacturer of cast and molded urethane for the automotive…

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.