Urethane sheeting is used in a broad range of applications due to its variety in size, durometer (hardness) and thickness. Sheets made out of urethane combine the strength and toughness of metal with the flexibility of a rubber and, if needed, also have the ability to be transparent. The strength and durability of urethane sheets allow them to be used in even the most severe applications and outlast other materials on the market.

A number of industries rely on urethane sheeting. Sectors such as aerospace, agriculture, automotive, and food processing benefit from the physical properties and longevity of urethane sheets. At PSI Urethanes, we offer standard and precision sheets as well as polyurethane pads. Watch our short video for more details on our urethane sheeting solutions.

PSI’s Urethane Sheeting Offerings

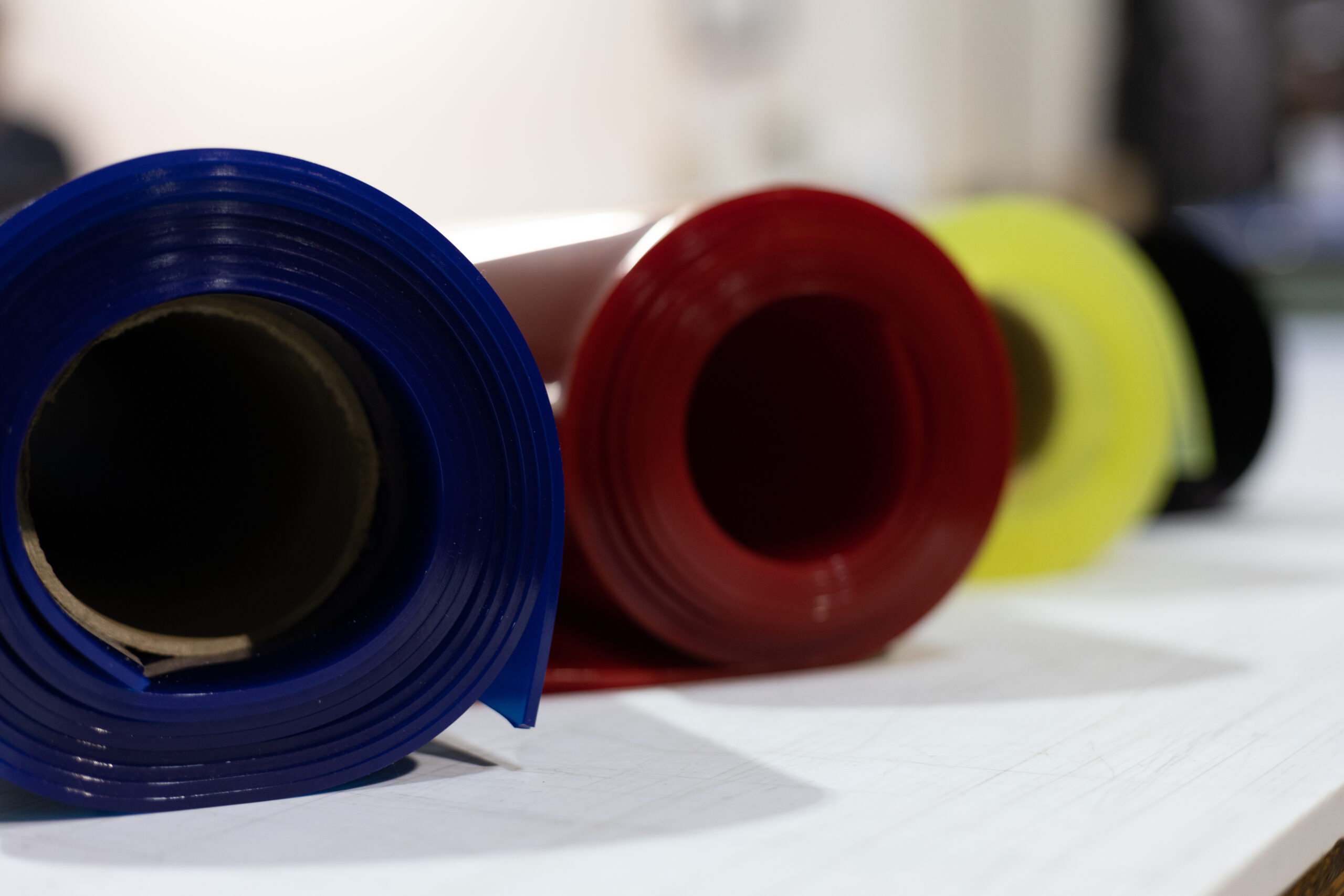

With a long history of outstanding quality, superior product performance, and excellent customer service, PSI is a trusted provider of custom and standard urethane sheets. When selecting a partner for your urethane sheeting, it is important to understand their suite of offerings. In general, a supplier that offers a variety of types and sizes enables more versatility and the ability to choose from a range of products to select the right one for your unique needs. For example, at PSI Urethanes we also offer a variety of colors, across a range of durometers and thicknesses. In addition, we create urethane formulations that are FDA approved for food processing services.

PSI’s single batch casting process allows us to manufacture sheets to your specific needs. Do you need to bond material to metal? We can produce precision cast sheets with no wax on one side or both, and our standard cast sheets with no wax on one side. This means you do not have to rough up your sheet material for it to adhere to a substrate permanently. Do you need a dual durometer sheet for a tough application? We can produce a range of thicknesses and durometers in dual durometer sheets to fit your exact application. Our process guarantees they will not delaminate, even under extreme pressure. Visit our website for more info on our urethane sheet stock features and availability. Our products include:

- Polyurethane Pads: we hand-pour our urethane pads to meet each customer’s specific needs. Standard durometers include 60A, 70A, 80A, and 90A, and custom durometers are also available. Polyurethane pads can be utilized in their flat state in applications such as table tops, cutting pads, and liners. Die cutters, waterjet cutters, and machine shops can convert these flat pads into simple gaskets, rings, seals, scrapper blades, or an array of other custom parts.

- Standard Sheeting: stock urethane sheets for the purpose of giving you a cost-saving avenue when tight thickness tolerances are not critical. PSI’s standard polyurethane sheeting meet the highest industry specifications for thickness and durometer, making them perfect for even the most severe applications. We keep stock of standard cast urethane sheets, so you can receive fast delivery. Standard cast urethane sheets can be produced in custom sizes to eliminate waste from drop-offs. For large sheet applications, we provide custom seamed sheets.

- Precision Sheeting: precision cast urethane sheeting comes in a variety of forms and custom formulations while still maintaining tight tolerances when seamed together. When requested, PSI offers tolerances as close as ±.001″. Our team works with our customers to ensure we create the right urethane formulation and product for your specific application.

Could your project benefit from the strength and durability of urethane sheeting?

Contact PSI today to learn more about our standard and precision urethane sheeting solutions and our commitment to quality.

Which Sheeting is Best for You: Standard or Precision?

Companies oftentimes ask – is standard or precision urethane sheeting the right choice for my application? Below are a few common factors to consider when deciding whether precision or standard cast sheeting would work best for you. At PSI, we are focused on helping you choose the right urethane formulation and product for your project and we are happy to assist with any questions you may have.

- Thickness: depending on the needs of your application, thickness may be a factor that impacts whether standard or precision sheeting is right for you. Precision cast sheets typically range from.010” to .125” in thickness with a standard tolerance of ±.005 and for a thickness of .125” to .375” the standard tolerance is ±.010. Alternatively, the standard cast sheets are available in ±.030 tolerance for standard sizes 24″ x 24″ and larger, and ±.045 for sizes under 24″ x 24″.

- Durometer: one of the benefits of urethane is that it has a wide range of durometers ranging from as soft as a marshmallow to as hard as a bowling ball. The durometer you require for your project may be a deciding factor in whether you select standard or precision sheeting. For example, precision cast sheets are available in 20 Shore A to 50 Shore D durometer for any thickness between .010″ to .375″ thick, with 60 Shore D to 70 Shore D for any thickness between .010″ to .125″ thick. Conversely, standard cast sheets are available in sizes that start at .125″ in thickness with all durometers up to 70 Shore D.

- Bonding: if your part will be bonded to a substrate may also influence whether you choose standard or precision urethane sheeting. In general, precision cast sheets can be made with no wax on one or both sides whereas standard sheeting is typically only available with no wax on one side.

About PSI Urethanes

Since 1966, through our own independent research and activity in the Polyurethane Manufacturers Association, PSI Urethanes has stayed on the leading edge of urethane technology – including developing advances in new materials, comprehensive designs, and processing technologies. Today we are among the most respected and trusted suppliers of custom polyurethane products.

We operate from our 45,000-square-foot manufacturing facility in Austin, Texas, which houses an extensive stock of polyurethane products. Our fully equipped manufacturing facility includes a versatile range of processing machinery, which allows us to work on unique, one-of-a-kind projects, as well as high volume components. Our in-house engineering, tooling, and custom mold shop, produces custom and stock production orders with exceptionally fast turn-around times. From conception to prototyping, to final production runs, our technical representatives and design engineers will work closely with your staff to meet your critical tolerances and specifications. You are guaranteed to receive experienced, professional, and personalized service from the first contact through your on-time delivery, with complete confidentiality and dedication to protecting your good name.

PSI Urethanes specializes in custom polyurethane products. Contact us today to see how we can help with your next project, or give us a call at 1-800-888-5156.