Cast Urethane Shock Absorbers

Urethane: The Ideal Compound for Shock Absorption & Vibration Damping

Used in severe machinery applications, electrical components, commercial aviation, and everyday elevators, polyurethane shock absorbers offer the chemical resistance and energy dispersal that other shock-absorbing materials cannot.

PSI can customize your shocks geometry, durometer, thickness and more to meet the design requirements and specifications of your project.

In many applications, urethane shocks are preferred to rubber shocks, as they do not degrade when exposed to oil, grease, smog, or ozone.

Available Custom Shock Absorber Specs

Durometer Hardness

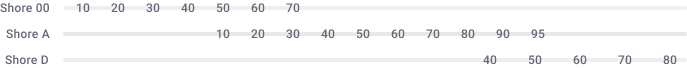

- 25 Shore OO

- 40 Shore OO

- 50 Shore OO

- 70 Shore OO

- 20 Shore A to 90 Shore A

- 50 Shore D to 70 Shore D

Here is a list of our standard durometer specifications and our technical brief, to assist you with choosing the correct material.

Durometer Reference Calculator

For reference, this hardness is as soft as a Gel Shoe Insole

For reference, this hardness is as soft as a Rubber Band

For reference, this hardness is as soft as a Pencil Eraser

For reference, this hardness is as soft as a Tire Tread

For reference, this hardness is as soft as a Shopping Cart Wheel

For reference, this hardness is as soft as a Hard Hat

Application Specific Formulations

- FDA Dry Food Approved 20A to 85A

- Static Dissipative material is available in 40A to 85A (other durometers may be available upon request)

- Dual Durometers

Benefits of Urethane Shock Absorbers

Urethane is renowned for its vibration-damping, shock absorbance, and abrasion resistance. It also does not take a permanent set when compressed. Urethane offers the following advantages to conventional shock absorbers:

- Oil and solvent resistant

- High load-carrying capability

- High dielectric strength

- Non-magnetic

- Protection against marring and galling

- Bondable to mating parts

Once installed, urethane shock absorbers help manufacturers reduce equipment downtime and cycle time limitations.

Urethane Shock Absorber Applications

Due to its unique strength, durability, and vibration damping qualities, urethane is the ideal material for a variety of applications. Urethane shock absorbers are often utilized in applications where corrosion, vibration, and magnetism prevent the use of conventional steel springs. Urethane shocks have proven to be a safe, reliable, and efficient as compression springs for stamping, punching, and drawing dies.

Call PSI To Help Protect From Shock Impact Damage

Call one of our experienced urethane professionals at (800) 888-5156 for design assistance and to get a quote for custom urethane shocks. You can also conveniently request a quote for any size project online, at any time.

In Simple Terms, What Is A Shock Absorber?

A “shock” is the result of a high impact force being delivered in a brief period of time. It’s a short duration event, involving a large magnitude of acceleration or deceleration, wherein one object encounters another. It happens when two things, any two things, collide. The resulting energy can cause damage to the affected items and ultimately, cause downtime and waste.

In order to avoid the damaging effects of shock exposure, some sort of shock absorption methodology must be employed to minimize the breakdown of equipment.

How Are Urethane Shock Absorbers Used?

Urethane shock absorbing pads effectively and safely disperse and absorb energy. Energy dissipates outward, away from the source of the shock impact, so that the object or the object’s internal components are not damaged. Urethane shock absorbers can come in many hardnesses and shapes. They are used in many applications, including grommets, pads, dampers, bumpers, bushings, sheets, rings, hemispheres, and more.

Industries Utilizing Urethane Shock Absorbers

Many industries rely on urethane shock absorbers for their needs, including:

Food Processing

PSI manufactures FDA approved urethane products for food processing applications.…

Metal Forming

PSI Urethanes is a leading manufacturer of cast urethane for metal forming press…

Military

We manufacture custom molded parts, polyurethane sheets, and bond to metal for the…

Die Cutting

Our quality and accuracy in keeping close tolerances make our company sought out…

Fluid Cell Remold

For industries that depend on highly complex parts to keep their equipment functioning,…

OEM's

Original Equipment Manufacturers (OEMs) utilize PSI Urethanes’ manufacturing expertise…

Marine

PSI Urethanes is a leading manufacturer of cast and molded urethane for the marine…

Process Automation

From rollers and bumpers to assembly systems and material handling, urethane is a…

Automotive

PSI Urethanes is a leading manufacturer of cast and molded urethane for the automotive…

Recommended Reads

Vibration Dampening and Shock Absorption with Shore OO

When it comes to Shock absorbing and Vibration dampening, PSI Urethanes has a wide range of durometers that can be utilized for both applications. Our shore…

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.