About Polyurethane

Polyurethane: Strong. Tough. Durable Versatile.

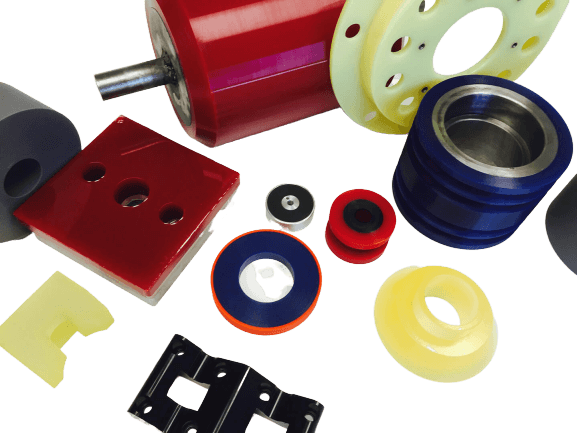

What problems do you have that urethane can solve? Do you face high-impact operations… or intense load-bearing applications … or harsh environments? PSI Urethanes, Inc.’s products can solve these problems and many more. We are the world’s leading supplier of urethane products that are stronger, tougher, more durable, and more versatile than any conventional elastomers and plastics available today.

Our products are scientifically formulated to be more resistant to abrasion, cracking, tearing, heavy loads, high impact, harsh environments, and more. In fact, when you use urethane you may never have to replace a worn out part again. That’s why smart companies in hundreds of industries around the world use PSI Urethanes’ polyurethane products for their critical business applications.

Learn More About Polyurethane

Polyurethane vs. Rubber

Many industries prefer standard urethane over rubber. Here is an example of the benefits of using standard urethane sheets versus rubber and its variations.

Learn More

Polyurethane vs. Plastic

In today’s industrial applications, the cost of material is not the only part of the initial set up and/or replacement to consider. Companies are trying to stretch their dollars and make them count. …

Learn More

Polyurethane vs. Metal

Many industries prefer the versatility and durability of urethane over metal. Here are just some examples of the benefits of using urethane material over metal.

Learn More

Polyester vs. Polyether

There are two main types of polyurethane: polyester and polyether. Both are highly effective in a diverse range of industries.

Learn More

Thermoset vs. Thermoplastic

What is the difference between thermoset urethane and thermoplastic urethane? Both can be used for a wide variety of applications in a variety of fields; however, because of their unique properties,…

Learn More

Choosing Polyurethane Material

Not sure what kind of polyurethane is best for your application? Each type of polyurethane has many different uses, and as such, each type has different properties.

Learn More

What is Thermoset Polyurethane?

Thermoset Polyurethane is a versatile material that, depending on how it is formulated, can range in physical properties from soft and malleable to tough and hard.

Learn More

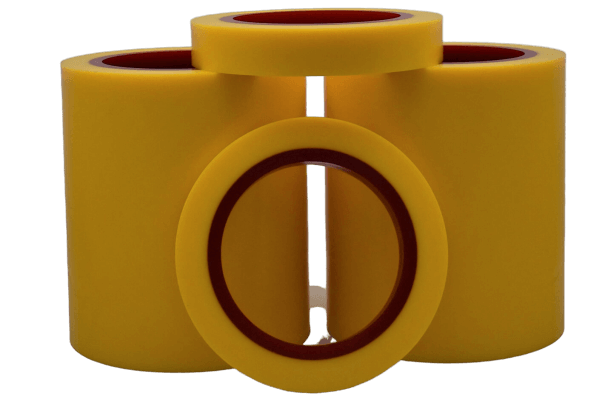

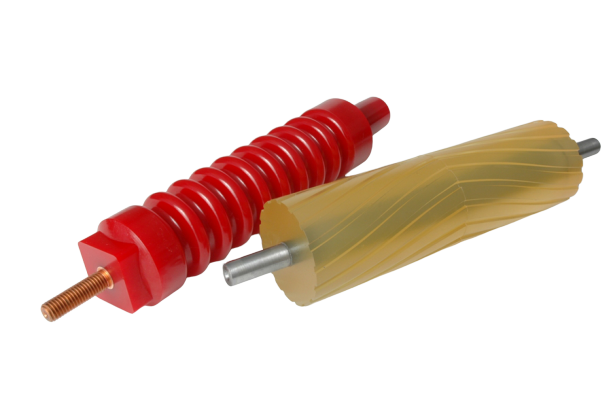

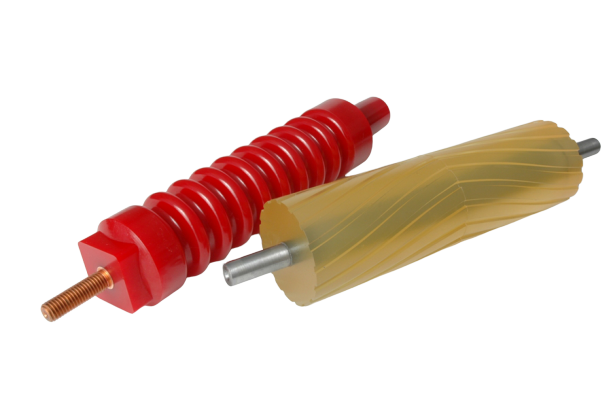

Urethane Elastomers

Most simply defined, an elastomer is an elastic material that can be stretched and will rebound to its original dimension and shape when tension is released. An elastomer has both viscosity (resiliency)…

Learn More

Soft vs. Hard Durometers

Have you been searching for custom urethane products but are not quite sure what the ‘durometer’ (also known as ‘hardness’) you need for your specific application(s)?

Learn More7 Reasons Why You Can Count on Urethane Products from PSI Urethanes

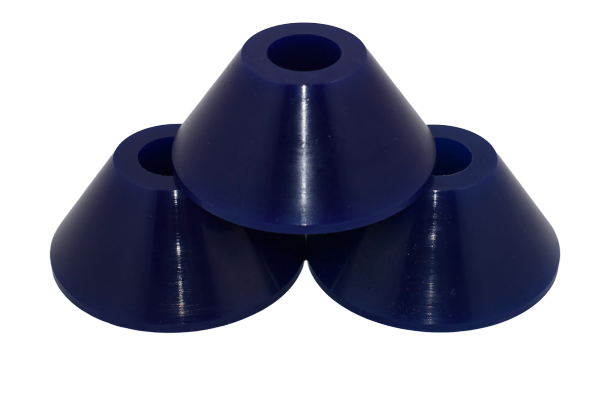

Durometer – Wide Range of Hardnesses

We can formulate urethanes in a wide range of durometers (hardness) from bowling ball hard (70 on the D scale), as well as, full A scale, to marshmallow soft (below 10 on the “OO” scale).

Abrasion and Impact Resistant

Urethane resists abrasion and holds up in high-impact applications.

- Abrasion resistant. When resistance to abrasion is critical, our high-performance urethane products stay on the job. In fact, our urethane products often outwear other materials from five-to-one to fifty-to-one when severe abrasion is a factor.

- Impact resistant. Are your parts subject to high impact or repeated impingement? Our urethane products remain elastic even in the hardest formulations.

Higher Load Bearing and Flexing Capacity

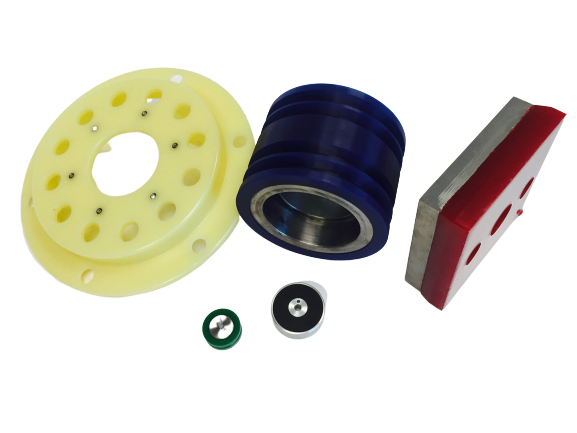

- High Load Bearing Properties. Urethane parts formulated by PSI Urethanes have higher load-bearing capacity than any conventional rubber. This makes urethane ideal for items such as high load-bearing wheels, heavy-duty couplings, metal forming pads, shock pads, and machine mounts.

- High Flex Properties. Our urethanes make great hinges and diaphragms. Because of the inherent strength and toughness of our precision cast urethane, we can make parts extremely thin at the flex point, which greatly reduces the risk of cracking that comes with thicker parts made of other elastomers.

High or Low Friction Variability

Friction against non-lubricated surfaces generally decreases with harder formulation and increases with softer formulations. We can formulate urethanes with low coefficients of friction for a variety of surface types.

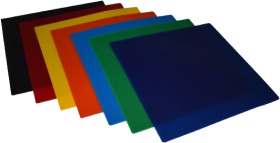

Strong Bonding Properties

Our urethane can be bonded to a wide range of materials during or after the molding process. Bonds on metal, wood, and plastic substrates are especially strong. In addition, our precision cast sheets can be manufactured without the use of mold-release or a wax base. Unlike other manufacturing processes that run the sheets through a secondary cleaning operation before bonding, our sheets go through a special process that allows them to stay mold-release-free (or wax-free). This technical advancement ensures an end product with even greater bonding properties than ever before.

Stable in Harsh Environments

- Harsh environments are no contest for our urethane products. Our sheets, pads, rollers, tubes, rings, and more stand up to temperature extremes and exposure to water, ozone, oxygen, oil, grease, and chemicals.

- Flexible at low temperatures. We can formulate urethanes to remain flexible in Arctic-like conditions or through sudden drops in temperature.

- Stable up to 250° F. Our experts can formulate urethanes to withstand continuous use up to 200° to 250° F.

- No swelling or deterioration in water. Our urethanes remain stable even when immersed in water as warm as 120° F for very long periods. (Although we don’t recommend continuous use in water hotter than 180° F.) Our precision-cast sheets, pads, rollers, tubes, rings, and other products absorb practically no water: approximately 0.3 to 1.0 percent by weight with negligible volume swell even after prolonged immersion.

- Electrical conductivity control. Customers frequently request our urethanes because of urethane’s excellent insulating properties. We can increase electrical conductivity to suit your needs.

- Resistant to ozone and oxygen. Our urethanes are virtually immune from attack by ozone and oxygen. Therefore, they’re the ideal performer around electrical equipment without the cracking and hardening associated with conventional elastomers and plastics.

- Resistant to oil, grease, and chemicals. Our urethanes resist a wider range of chemicals and substances than most rubbers and plastics. They perform well under contact with solvents, oils, and chemicals.

Wide Resiliency Range

Unlike rubber, urethane can be formulated to give a very wide range of resilience. For shock absorbing applications, our urethanes can be formulated with rebound values as low as 5% to 25%. For quicker recovery, rebound values of up to 70% can be formulated.

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.