Cast Urethane Parts Blog

Polyurethane in Mining Tools | PSI Urethanes

How Polyurethane Parts Enhance Mining Tools Polyurethane is a versatile synthetic polymer that has been used in various industries for decades. However, its use in the mining industry has been gaining traction in recent years due to its unique flexibility and other beneficial properties. In this article, we will explore the various uses of polyurethane [...]

Understanding The Shore Hardness Scale

The Shore Hardness scale is supposed to be a useful tool for understanding the properties of a material. However, there is some confusion surrounding the term, what all it entails, and how it applies to materials like the ones we work with here at PSI Urethanes. Today we’re here to clear the air surrounding this [...]

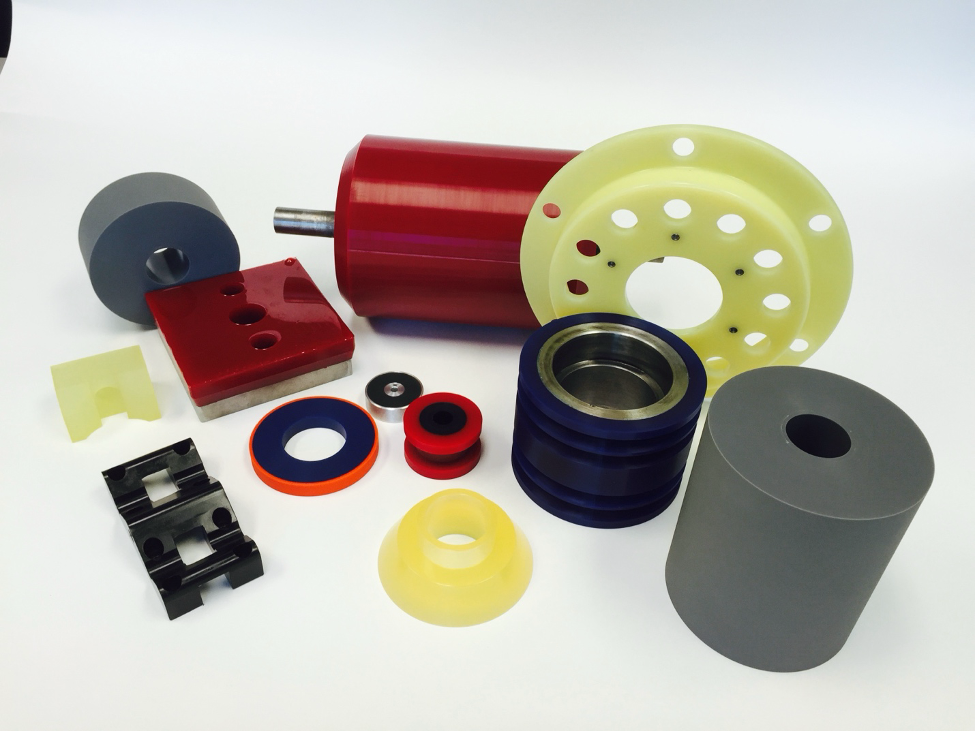

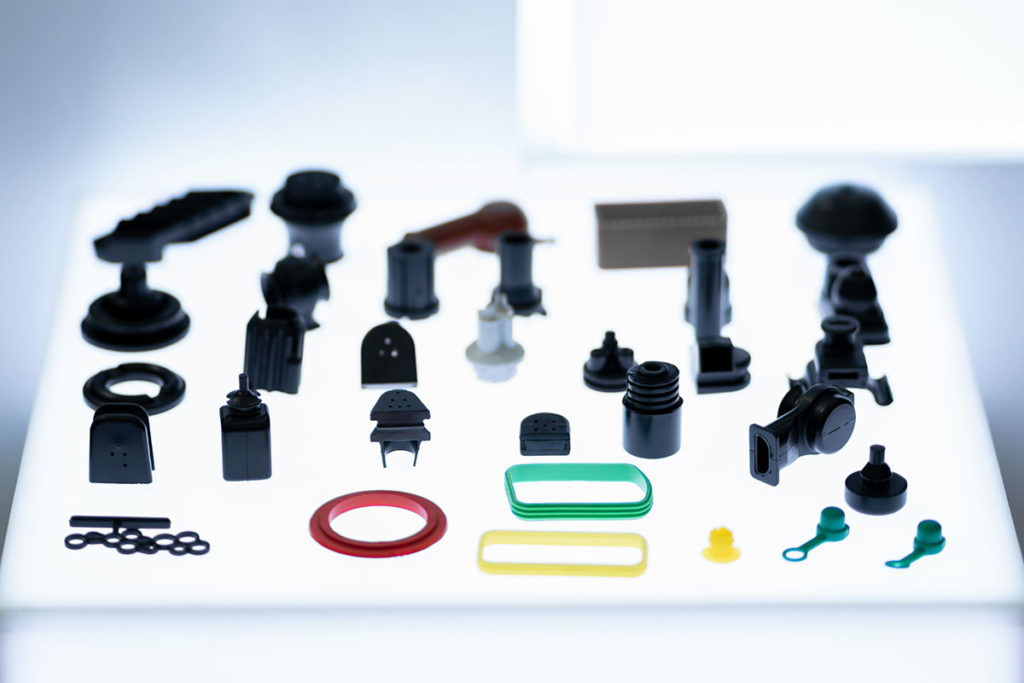

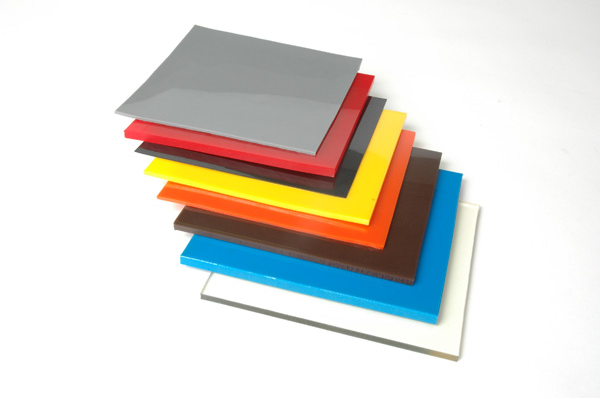

The Wide World of Urethane Parts

Polyurethane (PU) is one of the most versatile materials for making parts and products. It is available in a variety of sizes, durometers, formulations, tolerances and colors for use in a wide range of applications. In addition to the unmatched versatility it offers, polyurethane is also one of the strongest, toughest, and most durable materials. In [...]

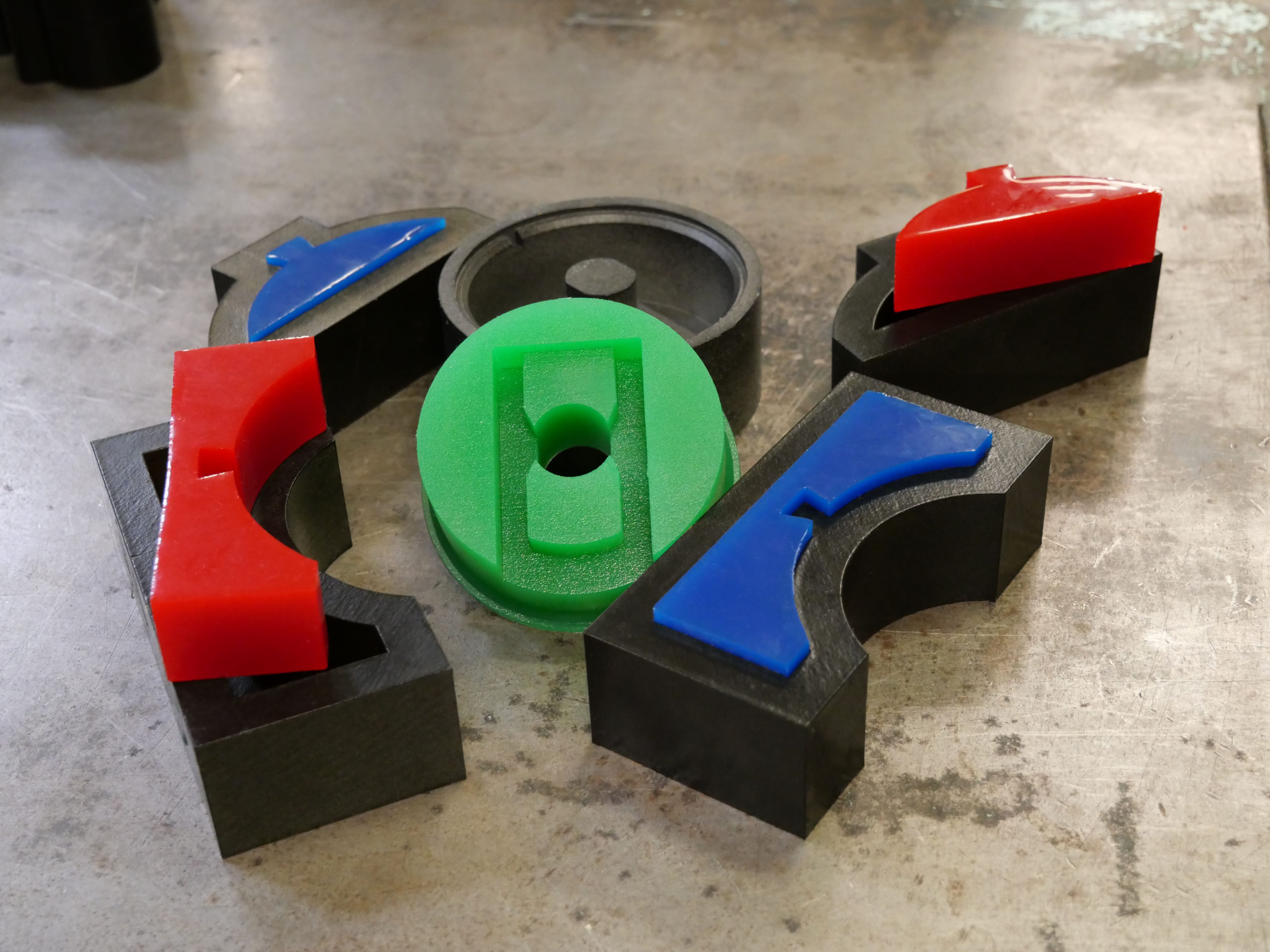

Designing Custom Urethane Parts for Unique Challenges

With a high degree of adjustability, urethane is a versatile and durable material option for industrial and manufacturing parts. However, sometimes unique applications arise where no standard urethane formulation may be suitable for a specific use case. It's during chances like these where our custom urethane manufacturing capabilities truly get the chance to shine. PSI [...]

Why Choose PSI Urethanes for Your Next Project

Your manufacturing projects deserve to be handled with utmost care from beginning to end. After all, quality doesn’t happen by accident when it comes to urethane products; it is the result of an understanding of a project’s needs, an extensive knowledge of urethane’s capabilities, and meticulous development to arrive at a solution that exceeds expectations. [...]

Advantages of Polyurethane Motor Mounts

When it comes to engine mounts, there are two common options: rubber and polyurethane. While rubber has been the traditional elastomer of choice for many years across different applications, polyurethane holds numerous advantages over rubber as a material choice for motor mounts and more. Polyurethane vs Rubber Motor Mounts Motor mounts, also called engine mounts, [...]

Thermoset vs. Thermoplastic Urethanes Explained

When it comes to choosing the right material for your project, it's important to understand the differences between thermoset polyurethane and thermoplastic polyurethane. Both are commonly used in various industries, but each type that has distinct properties and characteristics that make them suitable for different applications. In this article, we'll dive into the differences between [...]

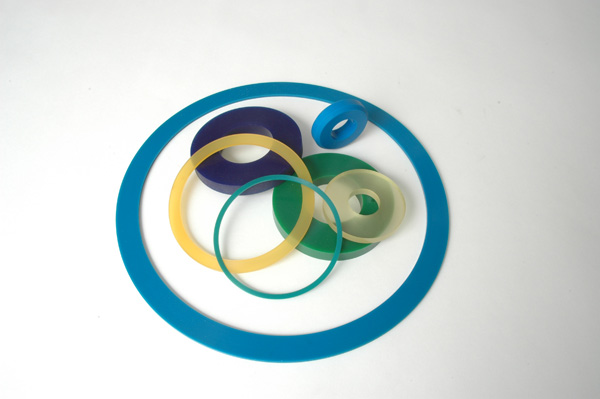

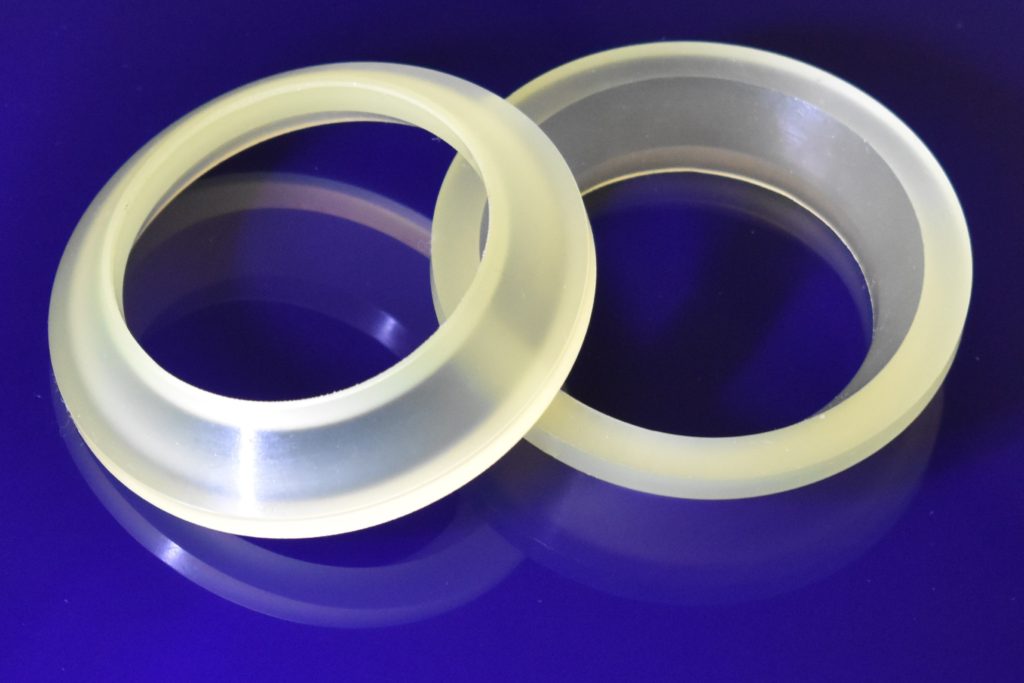

Elongate Machine Life with Urethane Rings

Elongate Machine Life with Urethane Rings Rings are an integral part of all types of machinery, from the simplest to the most complex. In some cases, rubber rings are selected for their flexibility and compression; other times metal rings are used for their strength and longevity. In either case, there is a material that can [...]

Determine Urethane Compatibility with This Handy Guide

Determine Urethane Compatibility Urethane is a versatile material that is used in a variety of industries, from automotive to construction. One of the biggest advantages of selecting polyurethane parts is that urethane formulations can be customized to suit nearly any industry application. While polyurethane is a material well-known for its excellent resistance to physical wear, [...]

FOOD GRADE POLYURETHANES IN AGRICULTURE

PSI Urethanes has developed two FDA-approved food safe urethane formulations. Learn how they boost efficiency & save costs in the agriculture industry!

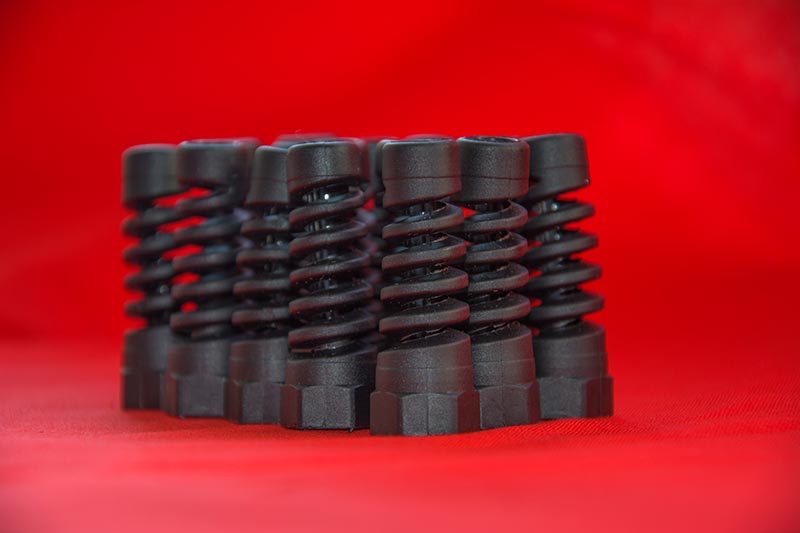

What Makes Polyurethane the Best Material for Shock Absorption

Shock Absorbers Explained Shock absorbers are used to dampen or absorb the force of high impacts between two objects. They can commonly be found in automotive, manufacturing, and robotics applications where two moving parts are designed to collide with one another. By absorbing and redistributing the force of impact, or “shock", shock absorbers can significantly [...]

When to Use Urethane Sheets for Die Cutting

Die cutting is a versatile manufacturing process that is used across a broad range of industries. In this process a cutting tool, or die, is used to cut a shape out of a sheet of material with great precision. Die cutting can be used to create all kinds of products from labels to insulators to [...]

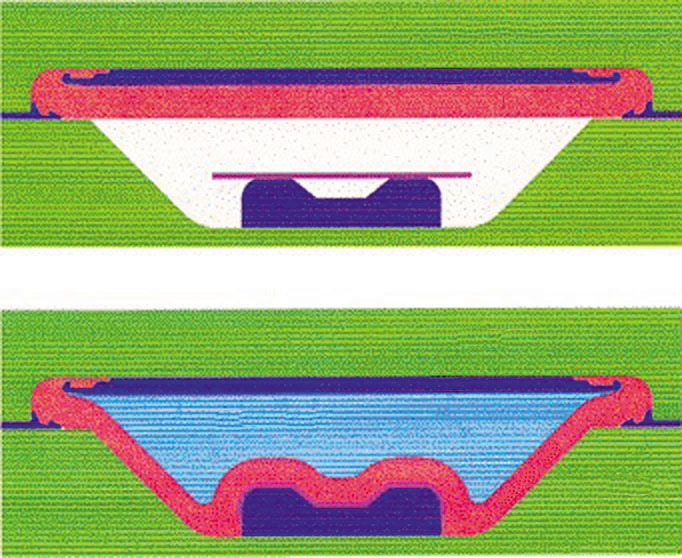

What is a Fluid Cell?

Fluid Cell Metal Forming Explained Fluid cells are an integral part of forming complex metal parts, primarily for the automotive and aerospace industries. To understand what exactly a fluid cell is and what it does, the clearest explanation we can offer is that of the metal forming process in which fluid cells are used: sheet [...]

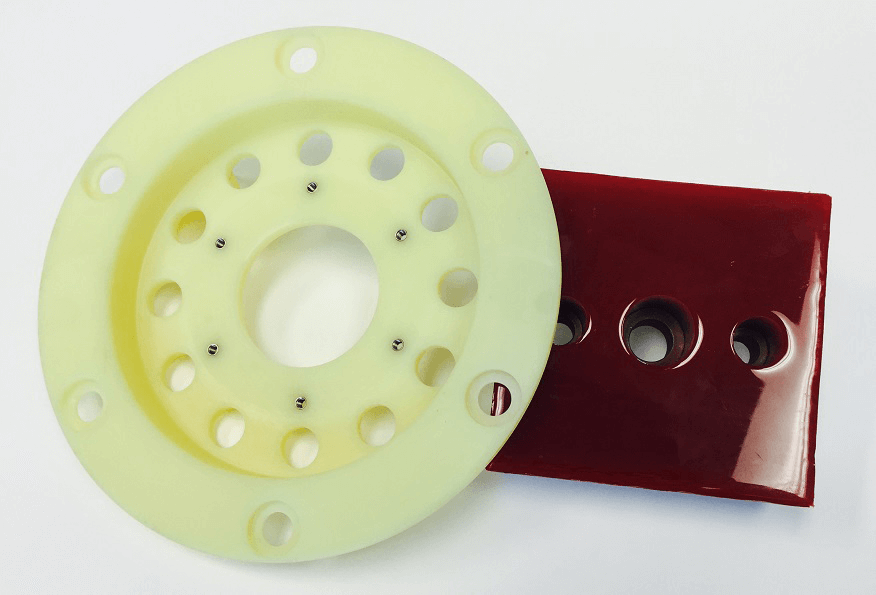

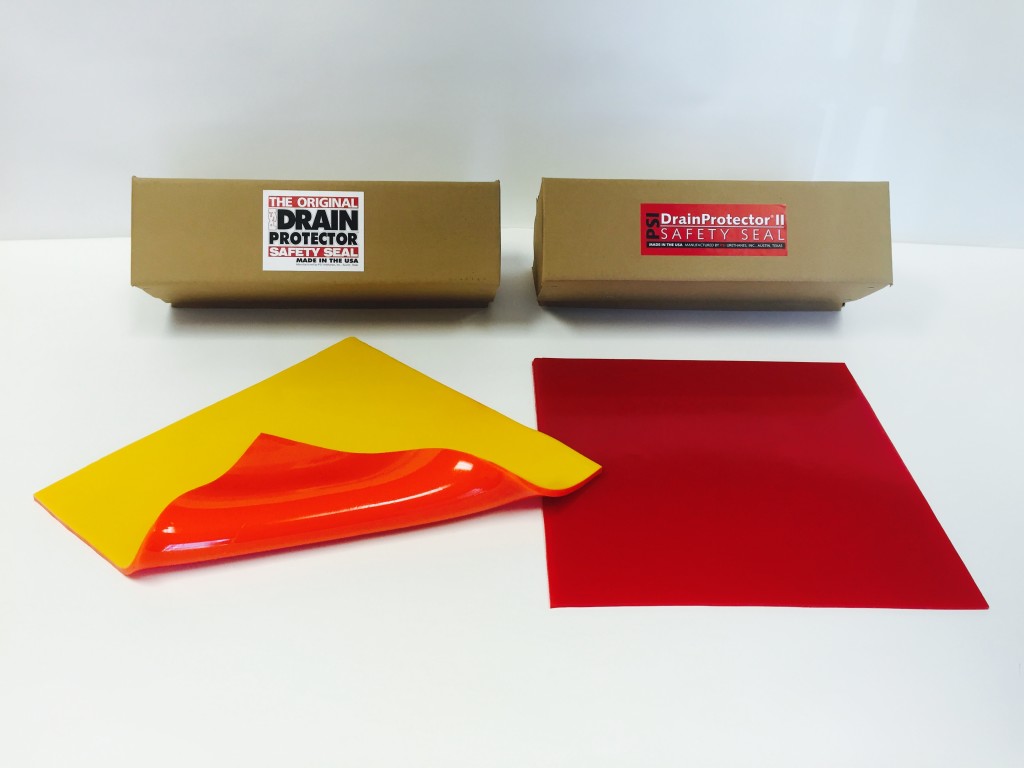

3 Common Types of Safety Seals Explained

Urethane as An Effective Spill Control Solution Urethanes are known for their strength and flexibility, but that’s not all that they have to offer. You may be surprised to learn that urethane products are also incredibly resistant to chemical wear. With this in mind, PSI Urethanes has developed urethane-based spill control solutions to mitigate spill-related [...]

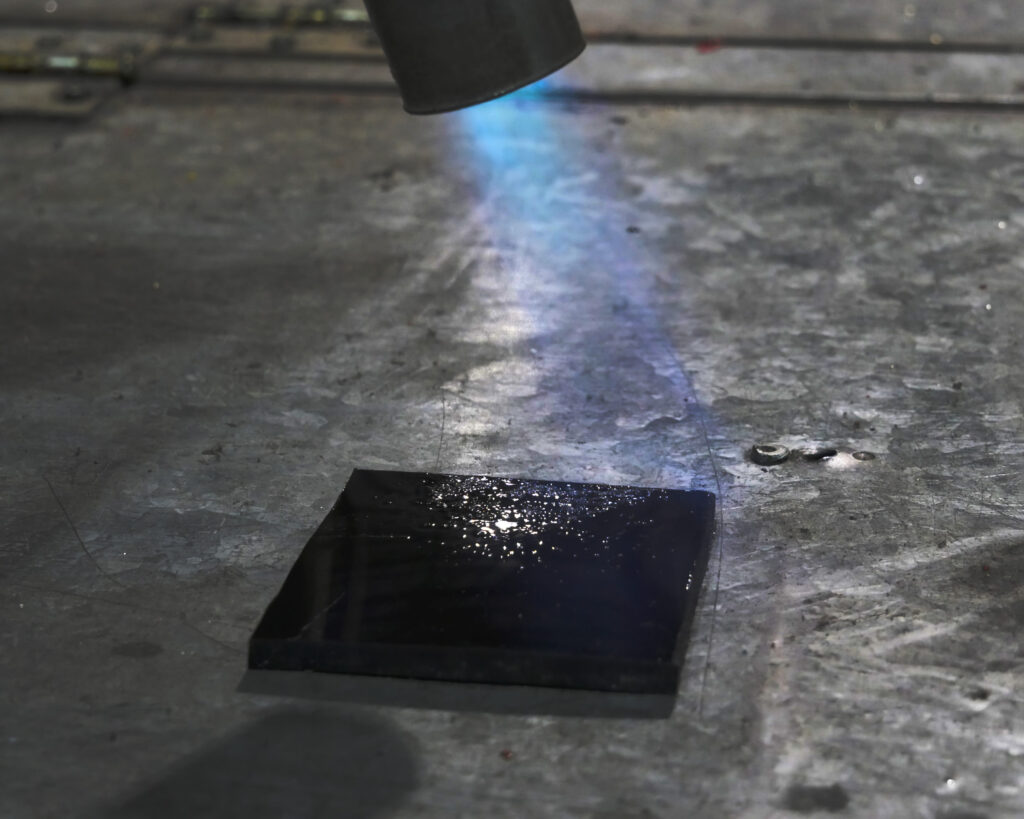

Flame Retardant Urethane Application

Urethanes are desired across a wide breadth of industries from food processing to aerospace for their superior physical strength and flexibility. While we’ve written plenty about the properties that make urethanes the material of choice in high-stress applications, you may be surprised to learn that urethanes can also perform well in high-heat environments. At PSI [...]

Why OEMs Choose Urethane

Advantages of Urethanes Over Other Elastomers OEMs rely on urethanes to outperform and outlast the competition. Other commonly used elastomers, like rubber and other plastics, often fail even when subjected to anticipated regular wear and tear. While metal parts can offer a higher strength than those materials, making that switch eliminates the flexibility, light weight, [...]

Custom Urethane Manufacturing at PSI Gives You More Control Than Ever

Custom Urethanes for A Different Set of Standards When compared to other elastomers, there is no better way to upgrade than by making the switch to polyurethane. Urethanes offer superior strength, longevity, and even dimensional accuracy when needed. So, when no standard urethane product is quite the right fit for your application, what more can [...]

Top Uses for Urethane in Metal Forming

Cast Urethane Parts in Metal Forming Metal forming facilities commonly find themselves in need of high-performance elastomers for use in their press systems. These facilities reach out to PSI Urethanes seeking cast urethane parts to replace and outperform less durable rubber components. Luckily, we have all the polyurethane expertise needed to improve production quality, reduce [...]

Dual Durometer & Multi-Layered Sheets

What Are Dual Durometer Polyurethanes? Polyurethane products are known for their wide assortment of versatile properties, namely for their range of durometer, or degrees of hardness. This adjustability allows urethane products to suit a diverse range of applications whether a rigid or soft component is right for the job. While there are several standard formulations [...]

Why Polyurethane Gaskets Outlast Rubber Gaskets

The Importance of Gaskets Gaskets are used to create a pressure tight seal between two pieces of jointed equipment. These components are all around us- in our cars, our food storage, and even some electronics. Gaskets prevent contaminants like dirt, oil, and debris from entering a system where they’re not wanted, and prevent leaks from [...]

Spill Control Solutions

Chemical Spill Containment & Prevention A chemical spill may sound like something that is always a disaster, but with the right spill control solution it doesn’t have to be. With the correct formulation, urethane products can be used repeatedly and reliably to contain spills before they spread out to a large mess, or to unwanted [...]

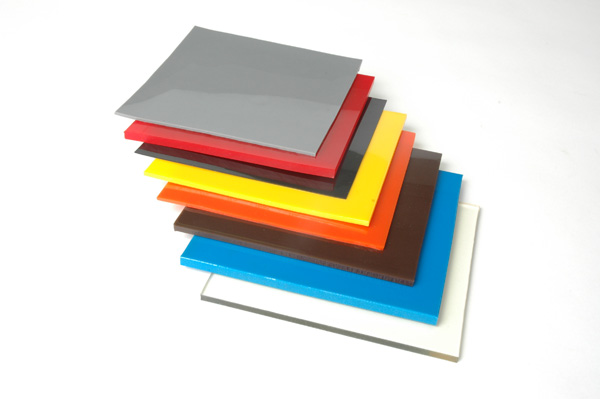

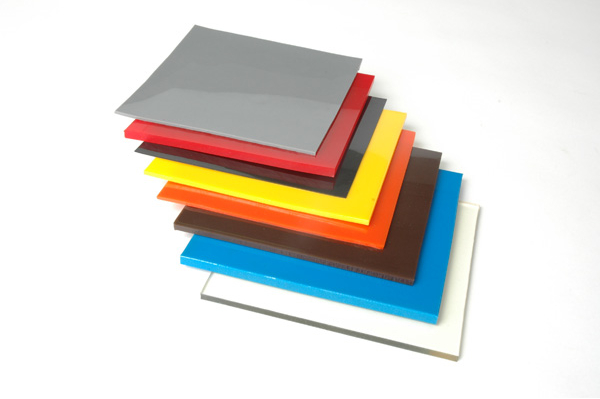

Standard or Precision Urethane Sheeting – Which Should I Choose?

Urethane sheeting is used in a broad range of applications due to its variety in size, durometer (hardness) and thickness. Sheets made out of urethane combine the strength and toughness of metal with the flexibility of a rubber and, if needed, also have the ability to be transparent. The strength and durability of urethane sheets [...]

Advantages of Urethane Rollers

Urethane rollers are essential to a variety of manufacturing processes. Due to their ability to stand up to harsh environments, urethane rollers are an excellent solution for high-stress applications. Additionally, these rollers are wear resistant and can carry higher loads than other materials with similar hardness. Many industries rely on polyurethane rollers for their outstanding [...]

How To Develop A Custom Urethane Product

Compared to plastics and rubber, manufacturing parts with urethane delivers more strength and durability in addition to a longer lifespan. As a result, urethane parts are often a more cost-effective solution. Urethane parts can be formulated and molded to exact specifications and produced with consistent quality – making custom urethane products an attractive option for [...]

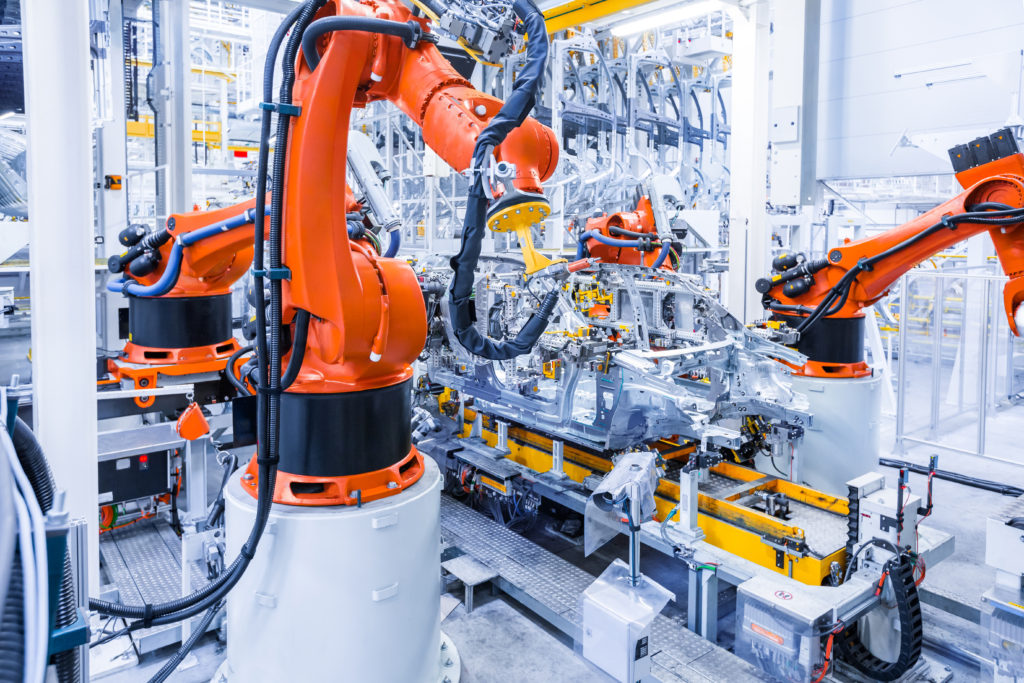

Urethane Applications in the Automotive Industry

All industries strive for continuous improvement and the automotive sector is no exception. The materials used in automotive applications continue to advance to meet the evolving needs of the sector, especially the drive towards lighter weight vehicles with more reliability and a better riding experience. Polyurethane is often at the center of these innovations. Urethane [...]

TDI versus MDI in Polyurethane

The properties and performance of urethanes can vary significantly based on chemistry; thus, it is important to understand what chemicals urethanes are typically comprised of in order to select the right materials for your specific application. The following explains one of the key aspects of urethane chemistry: isocyanates. The isocyanates most commonly utilized in polyurethane [...]

Why OEMs Prefer Urethane Rings Over Rubber

Rings are a simple but often integral element of manufacturing processes. If your application requires a material with unmatched durability, urethane rings are the way to go. PSI’s rings have several important applications and benefits due to their tough premium grade urethane, which ensures they will hold up across a wide range of applications. Common [...]

Benefits of Urethane Bumpers

Urethane bumpers are ideal for applications that require outstanding shock absorption, rebound, and abrasion resistance. Urethane bumpers are used in a variety of applications, including automated manufacturing systems, far surpassing the performance of rubber and steel. Depending on the service, PSI manufactures custom urethane tubes, rods, and rings for a range of bumper applications as [...]

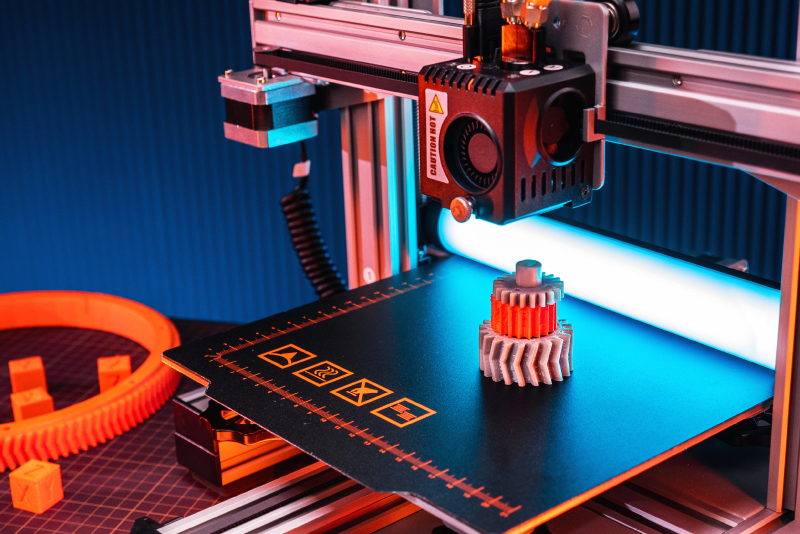

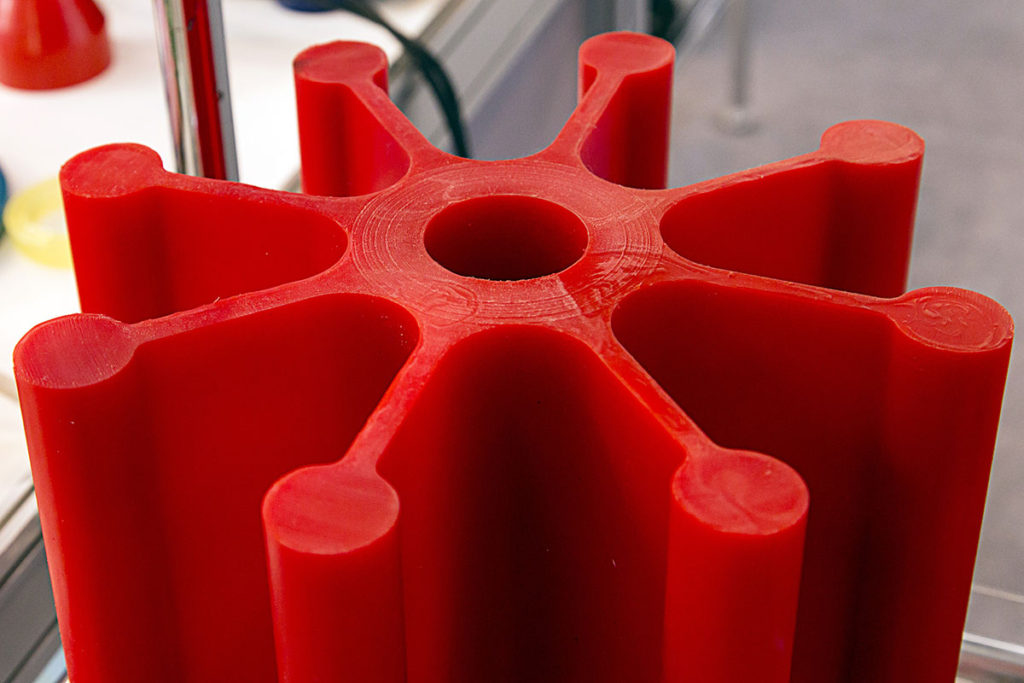

The Future of 3D Printing

Additive manufacturing (AM) methods are impacting the way manufacturers do business and are part of the digitalization of manufacturing that is often referred to as Industry 4.0. AM has evolved significantly in recent years. Due to these advancements, AM processes such as 3D printing for manufacturing are rapidly being adopted by many production processes worldwide. [...]

All About Polyurethane Durometers

There are many factors that will impact the performance, durability, and ultimately, the lifespan of your custom urethane product. When developing a polyurethane formulation, one key factor to consider is durometer. Durometer is a measurement of a material’s hardness. There are several scales used for durometer readings with Shore 00, Shore A, and Shore D [...]

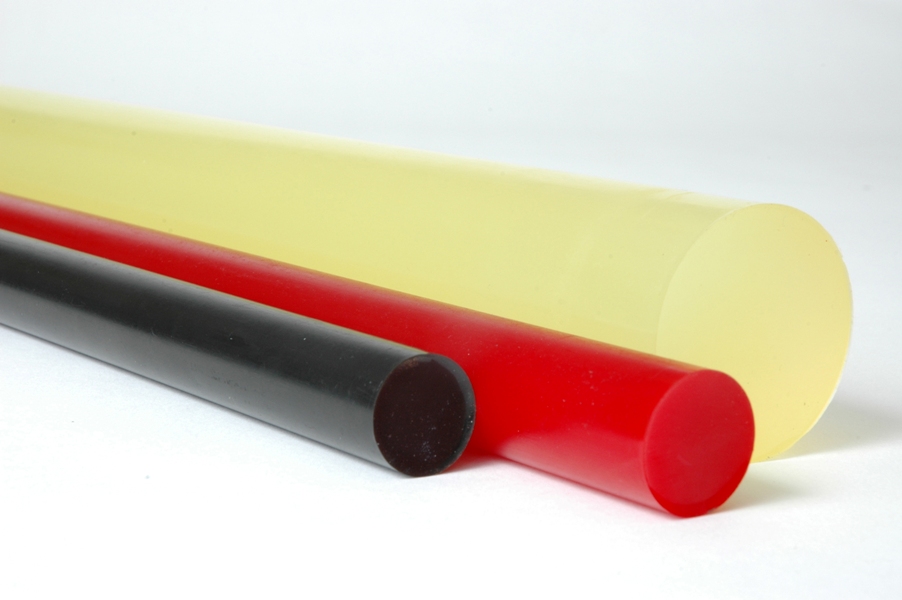

Advantages of Polyurethane Rods

With a long history of outstanding quality, superior product performance, and excellent customer service, PSI Urethanes is a trusted provider of custom polyurethane rods and polyurethane round rod stock. Our urethane products are scientifically formulated to be more resistant to abrasion, cracking, tearing, heavy loads, high impact, harsh environments, and more. Urethane rods offer several [...]

Food Grade Polyurethane Products

Companies all over the world are looking for even the slightest advantage in order to improve the bottom line and remain competitive. For this reason, material selection is receiving more scrutiny and is often an opportunity for improvement. Many industries, including the food and beverage sector, are turning from conventional materials to urethane products for [...]

How PSI’s Latest Machine Shop Upgrades Benefit Our Customers

There is one certainty in urethane manufacturing and that is change. While it comes in a variety of forms, every business can count on change and must be able to adapt in order to remain competitive. Manufacturers can never get too comfortable or they risk becoming complacent. A business that is not growing and evolving [...]

Why Polyurethane is the Preferred Material for Gaskets

Many industries are turning to polyurethane parts for a variety of applications. Polyurethane offers many unique advantages over conventional materials such as rubber. Urethane products deliver excellent product longevity and versatility as well as superior heat, chemical, and impact resistance. Urethane is quickly becoming the preferred material for parts that need to perform reliably and endure [...]

Polyurethane in Medical Robotics

In today’s competitive environment, OEMs are looking for opportunities to reduce costs without sacrificing product quality. One way that companies are realizing cost reductions is through process automation. Automation, and the efficiency it brings, has become a vital component in manufacturing. The technologies used in automation have advanced significantly in recent years due to the [...]

Polyurethane 101

Polyurethane is one of the most versatile materials for making parts. It is available in a variety of sizes, durometers, formulations, tolerances and colors for use in a wide range of applications. In addition to its unmatched versatility, polyurethane is also one of the strongest, toughest and most durable materials. In fact, urethane parts are [...]

Why OEMs Choose Polyurethane Tubes

Urethane tubes result in a stronger, more durable, and more versatile product than the competition. For this reason, urethane tubes are often a better value than tubes made with other materials that often crack, tear, and swell. Many industries rely on urethane for a variety of applications. Some common uses for urethane tubes include bumpers, [...]

3D Printing for Production

Additive Manufacturing, AM, is one of the fastest growing industries in the U.S. today. AM includes many benefits such as faster production, more design freedom, and less waste generation compared to traditional technologies. AM, commonly known as 3D printing, has advanced rapidly in recent years and companies are more readily incorporating 3D printing into their [...]

Why Partner with PSI Urethanes for Custom Urethane Products?

OEMs have many options to choose from when it comes to their custom urethane supplier – and it is essential to pick the right one. With 50+ years of experience delivering the highest quality custom urethane products, the professionals at PSI stand unequaled in helping companies in hundreds of industries around the world apply urethane products [...]

Benefits of 3D Printing

Additive manufacturing methods such as 3D printing are impacting the way manufacturers do business and are part of the digitalization of manufacturing that is often referred to as Industry 4.0. 3D prototype printing has been around for decades and is often referred to as rapid prototyping. In recent years, its popularity has grown and utilization [...]

Polyester or Polyether: Which is Right for My Application?

For over 50 years, PSI Urethanes has created urethanes that are stronger, tougher and more durable than products made from conventional elastomers and plastics. Urethanes also offer the engineer a remarkable range of physical properties to choose from. It is important to understand the chemistry of urethanes in order to select the right materials for [...]

Why the Automotive Industry Relies on Urethane Parts?

The applications for custom urethane parts have grown significantly over the years and urethane can be found in many different sectors including the automotive industry. Automotive environments are often harsh and materials used in these applications are vulnerable to chemical and physical deterioration. These factors make material selection a critical decision that directly correlates to [...]

Polyurethane’s Superb Abrasion Resistance

Polyurethane offers OEMs many attractive properties. One characteristic that distinguishes urethanes from the competition and delivers a huge performance advantage is its superb abrasion resistance. Abrasion resistance is a measure of a part’s ability to withstand and endure surface wear caused by friction. This property is often necessary in environments that experience consistent wear on [...]

What is Static Dissipative Polyurethane

Polyurethane elastomers are typically considered excellent electrical insulators. However, there are applications that require polyurethane to be a non-insulator to avoid electrical charge accumulation and the potential for discharge. These situations can be detrimental to part performance and longevity as well as create a dangerous environment – so it is imperative that the right material [...]

How does Urethane Compare to Other Elastomers?

Material selection is a key consideration when designing a new part or upgrading an existing design. Selecting the right material for a given application is crucial to a successful part design and performance in the field. A poor material selection can result in reliability or longevity issues or even have safety implications. For these reasons, [...]

Why Manufacturing Certifications and Compliance Matter

PSI Urethanes provides products to companies worldwide. For this reason, we must have a variety of compliance and certifications to suit various regulations and requirements across the globe. At PSI, our range of compliance and certifications demonstrate our commitment to quality and set us apart from other custom urethane suppliers. With 50+ years of experience [...]

Why Polyurethane is Superior to Metal, Plastic, and Rubber

Material selection is a key consideration when designing a part or upgrading an existing design - and there is no shortage of material options to choose from. Many industries prefer polyurethane as it offers many advantages over conventional materials like metal, plastic, and rubber. The following compares polyurethane to each of these conventional materials in [...]

Industries that Rely on Urethane Products

Polyurethane offers many unique advantages over conventional materials such as natural rubber, plastics, and metals – so it’s no surprise that many industries rely on urethane products for a variety of applications. Urethane products deliver excellent product longevity and versatility as well as superior heat, chemical, and impact resistance. Urethane is quickly becoming the preferred [...]

Urethane Bonding 101

At PSI Urethanes, we are known for our ability to deliver custom urethane products. One of our core competencies is urethane bonding, a process that bonds polyurethane to metal or various other substrates. Urethane bonding enables our customers to combine the benefits of multiple materials in order to meet the specific needs of a given [...]

3 Key Considerations for Custom Urethane Formulations

When designing a custom urethane product, there are countless formulation choices that will affect performance. Because of this, sorting through the choices to determine what is best for your product can be a daunting task. To help, below are 3 key considerations that should be discussed with your urethane supplier as part of the process [...]

Benefits of Reshoring Manufacturing to the U.S.

In today’s competitive environment, OEMs are looking for opportunities to strengthen their supply chain while maintaining excellent product quality. To achieve this, many companies are relocating manufacturing closer to home – a process known as reshoring. Over the past several decades, many North American OEMs transitioned manufacturing offshore, typically to locations in Asia such as [...]

How to Choose the Right Custom Urethane Partner

There are many factors to consider when choosing a custom urethane supplier and it is imperative that OEMs do their research to identify the right one. Price is, of course, a huge consideration, but there are many additional factors that must be considered when selecting a partner. Since there are many options to choose from, [...]

Are You Maximizing Runtime with a Polyurethane Liner?

Every industry strives to minimize equipment outages in order to maximize runtime. This approach results in the most efficient and cost-effective operations. One of the challenges to maximizing runtime in the transport sector is wear issues. Equipment wear and tear is often caused by repeated exposure to abrasive or corrosive materials as well as damage [...]

5 Tips for Inventors and Engineers Working with Urethane Manufacturers on Custom Urethane Products

When creating a custom urethane product, there are countless formulation choices that will affect performance and longevity. Sorting through the options to determine what is best for your product can be a daunting task. Below are 5 tips for inventors and engineers working with urethane manufacturers on custom urethane products. Clearly Define the Product Application: [...]

Polyurethane Specifications, Applications, and Chemical Urethane Compatibility

In today’s competitive environment, companies are trying to stretch their dollars and make them count. If you purchase a material that does not hold up to various operating conditions, your downtime can cost man-hours and production loss. These issues could have been prevented by choosing a superior product. Custom urethane products deliver important advantages over [...]

PU Formulation Tips: Selecting the Right Polyurethane Shore for Custom Urethane

Some products require a custom urethane formulation in order to achieve the desired properties and requisite specifications. When creating a custom part, there are countless polyurethane formulation choices that will affect performance. Sorting through the options to determine what is best for your product can be challenging. For this reason, it is helpful to work [...]

Food Safe Polyurethane Products: Working with Custom Urethane Suppliers on Approved FDA Polyurethane Solutions

Many industries are turning to custom urethane suppliers for polyurethane parts and products. One of the industries that relies heavily on polyurethane is food and beverage processing. This sector utilizes a broad spectrum of custom polyurethane parts in manufacturing, packaging, and transporting. Polyurethane products manufactured for the food processing industry include FDA approved rings, gaskets, [...]

Applications of Polyurethane Material: Is Polyurethane a Thermoset or Thermoplastic?

When working with polyurethane materials and formulations, it is important to understand the difference between thermoplastic and thermoset. Both polymers are advantageous to OEMs and are used in a wide range of applications across a variety of fields; however, because of their unique properties, each is best suited for specific applications. In order to better [...]

Polyurethane Compression Calculation Methods for Tool Development and PU Formulation

Polyurethane is a non-compressible elastomer, meaning its volume will not change. Polyurethane formulations are able to store up and return energy; for example, if you squeeze a urethane product in one place, it will bulge the same amount in another place, and then return to its original shape once the load is removed. This property [...]

3 Costly Design Mistakes in Urethane Springs

Springs are simply devices that absorb energy when compressed and release energy during expansion. As basic as springs are, their component function in machinery and equipment are essential to manufacturing. Springs come in a variety of types and can serve a variety of purposes. Steel alloys are the most commonly used spring material, but steel [...]

3 Benefits of Cast Urethane in Food Production

Many industries are turning to urethane parts and products for a variety of applications. Cast urethane offer many benefits over conventional materials such as elastomers and plastics including strength, toughness, durability, and versatility. One of the industries taking advantage of cast urethane is food processing. The food processing sector utilizes a broad spectrum of cast urethane [...]

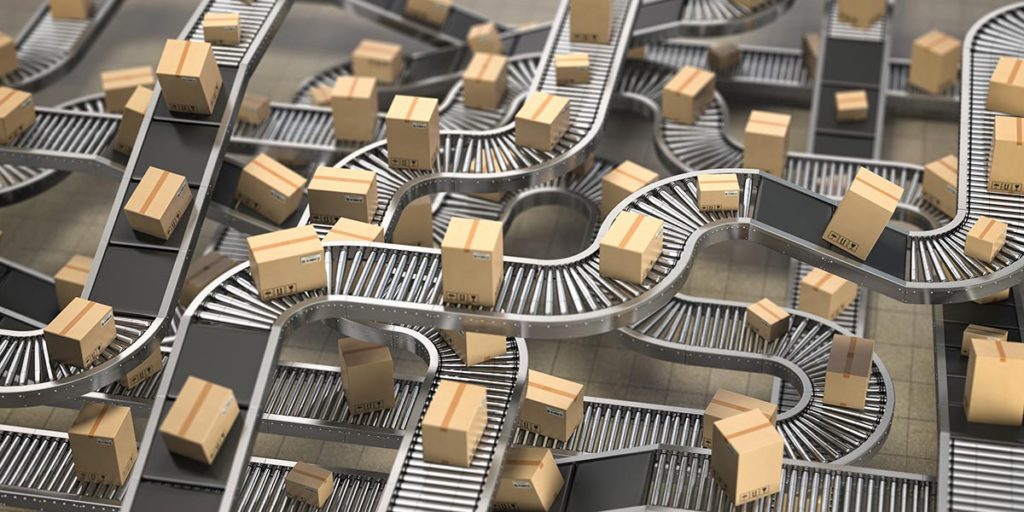

Why Urethane is Best for Conveyor Rollers

Most manufacturing and packaging facilities across the globe rely on conveyor rollers to smoothly process and transport products. It is imperative that rollers are robust and able to endure the often harsh and unrelenting demands of manufacturing environments. Due to its many advantages, urethane has become the go-to material and is the best for conveyor [...]

Spill Control Solutions for Hazardous Materials

Hazardous materials are utilized across a wide spectrum of industries and are present in many workplaces. These chemicals come in various forms and can be combustibles, explosives, flammables, corrosives, solvents, or oils. If not properly contained, hazardous materials present risks to personnel, facilities, and the environment as well as operations productivity. Fortunately, these risks can [...]

Plastic vs Urethane Sheets for Cutting Surfaces

Whether it be a manufacturing work bench or a table top for food processing, many industries utilize cutting surfaces. Companies have a range of material options for cutting surfaces including rubber, plastic, glass, metal, and urethane. Selecting the right cutting surface for your application is crucial – if you choose a material that does not [...]

Are You Choosing the Right Drain Covers for Your Industry?

Hazardous chemicals are utilized across a wide spectrum of industries and are present in many workplaces. These chemicals come in various forms and can be combustibles, explosives, flammables, corrosives, solvents, or oils. Industries that typically deal with such materials include hospitals, airlines, government sectors, oil and gas industries, chemical processing and manufacturing facilities, consumer product [...]

How to Reduce Equipment Downtime with Polyurethane Bushings

Bushings act as a protective interface between two parts and dampen the energy transmitted between the two, as the energy is redirected through the bushing. There are a variety of industries that employ polyurethane bushings such as transportation and manufacturing. An everyday example is the suspension system within a truck. The bushing resides between two [...]

Best Uses of Urethane for the Maritime Industry

The applications for urethane products have grown significantly over the years and urethane can be found in many different sectors including the maritime industry. Marine environments are harsh and materials used in these maritime applications are vulnerable to chemical, physical, and biological deterioration. These factors make material selection a critical decision that directly correlates to [...]

Smart Ways to Lower Tooling Costs with Urethane Products

Tooling is an integral element of the production process and is often one of the most expensive aspects of manufacturing. High quality tooling is essential, otherwise, companies run the risk of manufacturing lower quality final parts that are unable to meet specifications – resulting in higher production costs and longer lead times. Fortunately, there is [...]

5 Industries that Benefit from Urethane Sheeting

Many industries are turning to urethane parts and products for a variety of applications. Polyurethane offers many unique advantages over conventional materials such as natural rubber, plastics, and metals. Urethane products deliver excellent product longevity and versatility as well as superior heat, chemical, and impact resistance. Urethane is quickly becoming the preferred material for parts [...]

Which Durometer Should I Use For My Application?

Durometer Range Suggestions And Physical Considerations There are times when researching for a project, you need some qualifying information to get you started. Below, we have included a chart with suggested durometer ranges for various applications. In conjunction with that, we have listed physical properties that you should consider for each use.. Index of Physical [...]

Applications – Primary And Secondary Reasons For Use

Primary Use Secondary Use ApplicationsAbrasion ResistanceTear ResistanceTensile StrengthShock Absorption Flex Fatigue ResistanceLoad Bearing (Comp. Strength)Oil & Gasoline ResistanceLow Permanent SetLow Temperature FlexibilityResilience With High HardnessHigh Coefficient of Friction Bonds To MetalGalvanic Corrosion Resistance Belts: DriveBelts: ConveyorBumpersBushings: Shaft,Ball SocketCaster WheelsClutch FacingsCouplingsDiaphragmsDust BootsFriction Drive WheelsGasketsGearsGuide RollersHydroforming PadsLinings and SheathsMounts: Vibration IsolationMounts: Primarily SupportPackingsPump ImpellersRollers: PrintingRollers: Conveying Rollers: [...]

When Lead Time Is What Matters Most

Alternatives to Molding Thermoset Polyurethane Sometimes you just need parts quickly and do not have time to wait on molds and parts to be manufactured. Below, PSI Urethanes offers some suggestions to get a faster turn around, when your parts can be manufactured from a range of our standard rods, tubes, standard and custom cast [...]

Polyurethane VS Rubber Rollers

When it comes to choosing the right material for your industrial roller applications, you may have a lot of questions. If your existing equipment came with rubber rollers , should you go with rubber again? Let’s take a look at polyurethane and rubber and see how they perform. Do these materials have commonalities? Both are […]

Vibration Dampening and Shock Absorption with Shore OO

When it comes to Shock absorbing and Vibration dampening, PSI Urethanes has a wide range of durometers that can be utilized for both applications. Our shore “OO” material is excellent for both applications, as this video demonstrates. By definition, a shock absorber is any device used for absorbing sudden impulses or shocks in machinery or […]

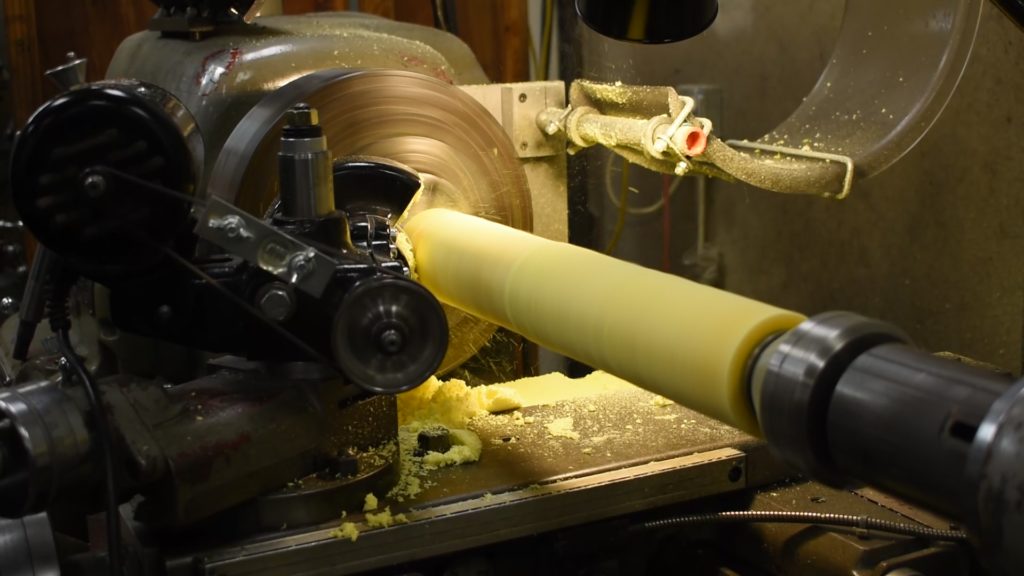

Machining Cast Urethane

Whether you are in the early stages of prototyping or want to save on tooling costs, machining parts out of urethane may be your cost-effective solution. Below are some tips to assist you with the process. Many machining operations such as turning, facing, milling, fly-cutting, and grinding can be performed as secondary operations. However, machining [...]

Stress/Strain – The Cause of Hysteresis

You might remember your high school physics teacher saying "for every action, there is an equal and opposite reaction." That’s a good way to think about stress/strain. Stress is a measure of the internal reaction force. Strain is the measure of deformation. These terms are used to define the intensity of internal reactive forces in a [...]

Urethane Rings vs Rubber Rings

So many industries turn to PSI Urethanes for urethane rings. Bottling companies use PSI’s urethane rings as torque wheels; companies with conveyor belt systems use them as bumpers; and still other production facilities will slip urethane rings on a shaft and use them as an idler roller. As versatile as urethane rings are, there’s an […]

Why Urethane is Best for Industrial Applications

When compared to rubber, metal, and plastic, urethanes versatility is undeniable, which makes it the preferred material for many industrial applications. See how urethane stacks up against its top competitors in the context of everyday industrial applications. Make sure you're using the best material for your needs, your budget, and the safety of your employees! [...]

Which Type of Urethane Sheet Do I Need For My Application?

When it comes to shopping for the best urethane sheeting for your application, you can’t go wrong with sheeting from PSI Urethanes. One type of sheeting, however, may best serve the unique purposes of your application, better than others. Whether you need the right sheeting for chutes, gaskets, cut shapes, linings, covers, sorting/conveyor parts, or […]

Tips for Preventing Hazardous Chemical Spills

Maintaining a safe workplace is essential for companies that work with hazardous materials, not only to meet OSHA and EPA requirements, but also for the well-being of employees. Whether handling, transporting, or storing hazardous chemicals, it’s important to take steps to prevent hazardous chemical spills, as well as prepare for them. Accidents happen, but a […]

Advantages to Choosing Urethane Gaskets Over Rubber Gaskets

Urethane is the toughest of all elastomeric materials and is the preferred material for gaskets due to its ultra-high strength and durability under pressure. Learn more about the distinct advantages urethane offers over rubber for gasket applications, plus how PSI Urethanes can support your gasket needs with precision cast urethane sheeting for gaskets. What’s A Gasket? […]

Durometer vs Design: Two Key Variables for Longer Performing Capper Rings

When it comes to capper ring applications, all operations are set up differently and have specific requirements that come into play. We frequently hear the question, “How can I get the best longevity from our capper rings?” To answer this, it all comes down to your application and the formula. There are different variables that […]

PSI Urethanes Spill Control Products: Dependable and Reliable

PSI Urethanes has been the industry leader providing dependable safety seals in drain covers, barrel patches and conical plugs for over 25 years. PSI regards compliance with OSHA regulations and the Environmental Protection Agency (EPA) as vital. That’s why we manufacture spill control products that are trusted on job sites at thousands of companies around […]

Custom Cast Urethane Rollers: Time to Re-cover Used Rollers?

There are several reasons that urethane rollers are the go-to choice for many industries including food processing, steel, marine, and packaging, to name a few. Wearability is the main concern for our customers, as some are looking to recover or replace what they are currently using due to wear and tear. Urethane has the ability […]

Precision and Standard Cast Sheeting: What is Best for Your Needs?

When deciding whether precision or standard cast sheeting would work best for you, there are a few things to consider. The differences may include the thickness and/or the durometer and deciding whether or not you need to apply adhesive. Below are some initial questions and answers to help you choose the right material. 1. What is […]

FDA Compliant Material In The Food Industry

There are many areas in the food industry that require FDA compliant material. Urethanes that are used as the surface layer and guides on conveyors, tubing for conveying certain liquids, table tops, and capper rings for the bottling industry, are just some examples that are required to be FDA Compliant. There are two different types [...]

Custom Urethane Products: Ideal Solutions for a Variety of Applications Part 2

Custom urethane products are an ideal solution for a variety of applications. In part one of this blog post series we covered two situations where urethane performs better than other materials. In part two of this series we take a look at several other applications for custom urethane products.

Custom Urethane Products: Ideal Solutions for a Variety of Applications Part 1

Custom urethane products are an ideal solution for a variety of applications. In this blog post series we will cover several of these situations along with examples of how companies have turned to custom urethane parts and products for their applications.

Choosing a Custom Urethane Provider: Key Points to Consider

Custom urethane has become the preferred solution for a variety of parts and products because of its versatility and durability, especially when compared to other options such as rubber or plastics. When you switch to custom urethane products, custom sizes, shapes and thickness levels can be requested to fit your specific requirements. In choosing a […]

From Order to Delivery: The Custom Urethane Provider Capabilities Checklist – Part Two

Part one of this blog series covered specific qualifications to look for related to a custom urethane provider’s quality of product. Part two covers the rest of the process: fulfillment and customer service. While it is important to ensure that your custom urethane product has the correct specifications for your needs, it is equally important […]

From Order to Delivery: The Custom Urethane Provider Capabilities Checklist – Part One

Compared to plastics and rubber, manufacturing your parts with urethane materials offer you: More versatility, strength, and durability Longer lifespan More customization As a result, urethane parts are often a much better value. Urethane parts can be formulated and molded to a project’s exact specifications and produced with consistent quality. In order to get the […]

Urethane Rings: Applications, Benefits, and Choosing a Manufacturer

Urethane rings have several important applications and benefits due to their tough premium grade urethane, which ensures they will hold up in a wide range of applications. Urethane rings can reduce equipment downtime and provide material cost savings.

Understanding Urethane Tubes: Benefits, Applications, and Choosing a Manufacturer

Many organizations rely on urethane tubes for a variety of applications. Urethane tubes result in a stronger, more durable, and more versatile product. They are commonly viewed as a better value, because tubes made with other materials often crack, tear, and swell.

Urethane Rods: Benefits, Applications and Choosing a Manufacturer

Urethane rods have several important applications and benefits due to their elastomeric properties. They are more crack-resistant, abrasion-resistant, durable, and have long-lasting characteristics. Rods made out of polyurethane last significantly longer than those made from conventional plastics and rubbers.

The Wide World of Urethane

Polyurethane is one of the most versatile materials for making parts and products. It is available in a variety of sizes, durometers, formulations, tolerances and colors for use in a wide range of applications. In addition to the unmatched versatility, polyurethane is also one of the strongest, toughest and most durable materials. In fact, urethane […]

Five Qualifications to Look for When Selecting a Custom Urethane Manufacturer

The lifespan and performance of your custom molded urethane parts heavily depends on many factors, including design, quality, formulation and tolerances. If these factors are lacking, your product performance will as well. To get the highest quality custom urethane products with the best overall performance, there are five key qualifications to look for when selecting […]

From Quote to Delivery: The Custom Urethane Order Process

When ordering a custom urethane product from PSI Urethanes, our in-house urethane experts will work closely with you on the entire process, from quoting to production to fulfillment. Through each stage of the custom urethane quote process, we ensure that the correct custom urethane product is ordered and arrives when needed. Overview of the custom […]

Understanding Urethane Rollers: Benefits, Types and Applications

Many organizations rely on urethane rollers for a variety of applications. Rollers made of urethane are wear resistant and can carry higher loads than other materials with similar hardness. In this blog we will explore the wide range of urethane roller types, the industries that turn to urethane rollers for their needs and how to […]

Spotlight On Urethane Sheets: Benefits, Industry Use and Choosing a Manufacturer

Urethane sheets are used in a wide range of applications due to their variety in size, durometer (hardness) and thickness. Sheets made out of urethane combine the strength and toughness of metal with the flexibility of a rubber and, if needed, also have the ability to be as transparent as glass. The strength and durability […]

Custom Urethane Parts & Products: Unique Advantages for a Variety of Industries

Many industries are turning to urethane parts and products for a variety of applications. Polyurethane products deliver many unique advantages over conventional materials such as elastomers and plastics – they are stronger, tougher, more durable and versatile. This blog post will highlight how the extensive benefits of polyurethane products serve a variety of industries. 1. […]

Custom Urethane Parts and Products: What to Tell Your Supplier – Part 2

In part 1 of this series, we covered two of the five critical areas that need to be discussed with your urethane supplier when ordering custom urethane products. In Part 2, we will cover three additional areas you should communicate to your supplier in order to achieve an optimal product or part design. 3. Product […]

Custom Urethane Parts and Products: What To Tell Your Supplier: Part 1

When ordering custom urethane products, it is important to communicate your specific needs with your supplier. Doing so will enable your supplier to formulate the ideal urethane part or product based on your specific needs for tolerance, durability and more, and do so cost-effectively. Critical Product Information for Optimum Design There are many questions your supplier will […]

Precision Cast Urethane Sheets: Top 3 Benefits for Seal and Gasket Cutting Material

Seal and gasket cutters need precision cast material because customers demand it. Seals and gaskets fill the gap between two objects to prevent leakage and act as a vibration dampener while under compression. Seals and gaskets must not only ensure a tight seal, but also be durable enough to hold up in a wide range of [...]

Welcome

Welcome to the PSI Urethanes blog! We are thrilled to begin to engage with our customers through this method of communication and hope that you find the material that we post interesting and useful. Our goal is to make frequent contributions to this blog where we will offer industry news and new product information. PSI […]