Cast Urethane Washers

Providing Excellent Mechanical Strength & Wear Resistance

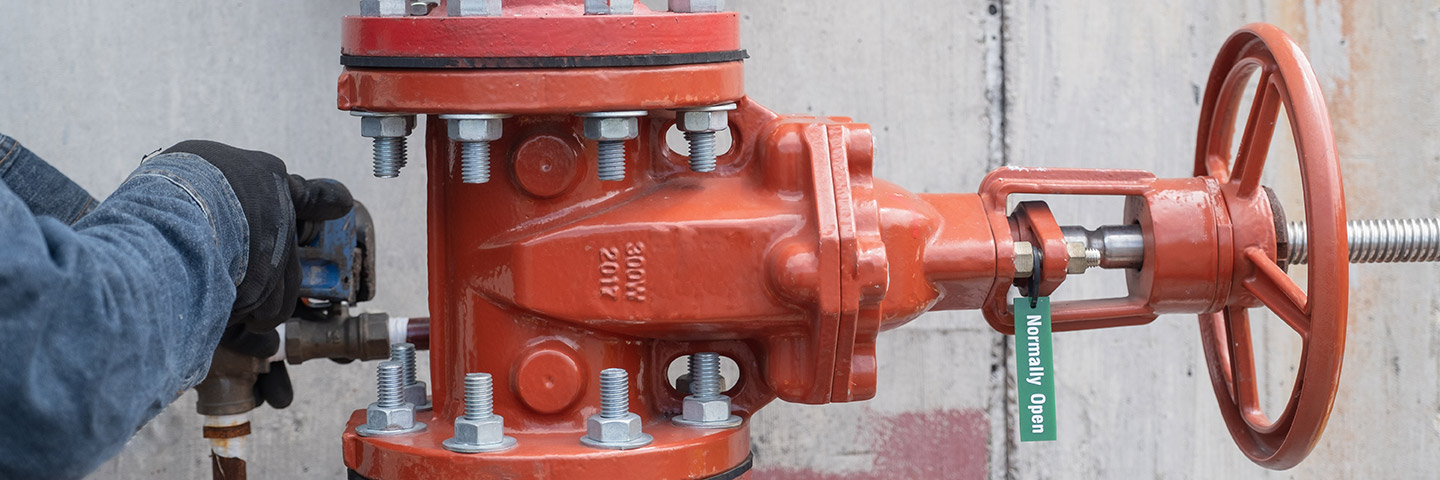

Urethane washers are used in multiple industries and can have numerous applications but are especially useful when assembling mechanical parts using bolts and nuts.

Molded urethane washers are used in a variety of industries including construction, aerospace, electrical and automotive. Urethane washers are fundamental to the function of many engineering processes and machinery.

Polyurethane washers are renowned for their high tear strength, good wear resistance, and aptitude for sealing and cushioning.

Available Custom Washers Specs

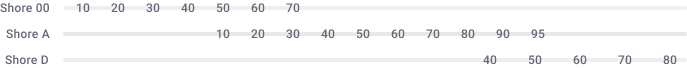

PSI excels in meeting your needs for custom polyurethane washers. PSI offers custom sizes, formulas, colors, and durometers (hardness), as well as tight tolerances, ground finishes, and dual durometer rings to meet the specific needs of your business. Select from a range of flexibility in hardness and gain increased durability over an alternative rubber washer with urethane washers from PSI. Our most common hardness options are:

Durometer Hardness

- 25 Shore OO

- 40 Shore OO

- 50 Shore OO

- 20 Shore A to 90 Shore A

- 50 Shore D to 70 Shore D

Here is a list of our standard durometer specifications and our technical brief, to assist you with choosing the correct material.

DUROMETER REFERENCE CALCULATOR

For reference, this hardness is as soft as a Gel Shoe Insole

For reference, this hardness is as soft as a Rubber Band

For reference, this hardness is as soft as a Pencil Eraser

For reference, this hardness is as soft as a Tire Tread

For reference, this hardness is as soft as a Shopping Cart Wheel

For reference, this hardness is as soft as a Hard Hat

Additional Customizations

Our staff members are happy to assist you with your urethane washer/seal project, from prototype to full production. To receive the most accurate quote, please have the following information on hand:

- Desired Color

- Outer Diameter

- Inner Diameter

- Thickness

- Tolerances

- Durometer

- Application

- Chemical exposure

What Are The Benefits of Urethane Washers?

How Do Urethane Washers Out Perform Rubber?

- Better abrasion resistance and tear resistance

- Can be manufactured in a spectrum of color, sizes and durometers(hardness)

- Non-marking

- Will rebound after being compressed and excellent for shock absorption.

- Will not become brittle over a long duration of time under normal circumstances

- Ozone resistant

How Do Urethane Washers Out Perform Metal?

- Will not gall or scratch mating parts

- Non-Conductive

- Cost Less

- More flexible

- Abrasion resistance

- Corrosion resistance

- Impact resistance

What Are Some Applications for Urethane Washers?

Urethane washers are optimum vibration dampeners and can remain flexible at low temperatures. They perform well when utilized in abrasive resistant situations and are highly resistant to water, weather, hydrocarbon, mineral oils, and most chemical substances. Urethane washers also have tight sealing capabilities and since urethane is an elastomer, they can conform to nearly any shape.

Call PSI for a Custom Quote

Call one of our experienced application engineers today at (800) 888-5156 to learn more about urethane washers or request a quote for your custom urethane project online at any time.

What Are The Type of Washers?

A washer is a thin, flat disc with a hole in the center. Depending on the construction material, washers can be used to distribute the load of a threaded fastener (like a screw or a nut), reduce vibration, prevent galvanic corrosion, or act as a spacer, spring, wear pad, locking device, or seal. There are generally three types of washers: plain washers, spring washers, and locking washers.

Plain Washers

Plain washers disseminate the weight of a load to prevent a surface from being damaged or to provide electrical insulation.

Spring Washers

Spring washers are flexible enough to prevent a fastening from loosening due to intense vibration.

Locking Washer

A locking washer can also be a spring washer; locking washers prevent materials (like a nut/bolt) from unfastening and coming loose.

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.