Custom Polyurethane Products

Engineering Support to Help You Beat Tough Problems.

PSI Urethanes, Inc. welcomes the challenge that custom polyurethane products can bring. When other companies have turned away potential clients, we welcome the opportunity to do the unusual and, the seemingly impossible.

Cast urethane parts can be formulated and molded to exact specifications and produced with consistent quality, making custom urethane products and parts an attractive option for a wide range of industries. Our in-house engineering and technical assistance staff can help you create custom molded urethane parts that meet your application needs and solve your problems. We have a wide range of formulations that can be tailored specifically to your requirements.

Materials

In-house resins for cast urethane parts include TDI ethers and esters, MDI ethers and esters, and aliphatic resins. With these resins, we can manufacture durometers from 25 shore OO (soft as a marshmallow) to 70 shore D (hard as a bowling ball). All our formulations can be produced in a wide variety of shapes and sizes. If you require a resin that we do not carry in-house, we can order it and manufacture your products.

Custom Formulations:

- Static Dissipative - 40A to 85A durometers (additional durometers may be available upon request)

- Graphite Embedded

- FDA Dry & Wet Food Approved

Custom Molds

Our in-house mold making shop has been updated to include a versatile range of processing machinery, including a CNC Mill and multiple CNC Lathes. This new machinery has opened our capabilities to machine aluminum molds that are more intricate than ever before. With this new equipment, we are able to cut our lead times for your custom production orders with more efficient mold manufacturing and in most cases, by cutting out a secondary machining process to finish out parts.

If you have a unique, one-of-a-kind project that requires only a few parts or if you are needing to test out a part prior to purchasing a multiple cavity metal mold, PSI Urethanes now offers 3D printed molds for producing small runs. There can be some limitations, such as design, size and surface finish, however the cost is significantly lower and lead time is faster than producing a custom metal mold. Ask your sales associate if your project is a good candidate to be produced with a 3D printed mold.

PSI produces cast urethane products and parts ranging in size from less than a gram to over 2500 pounds. We are known for our willingness to do short-run production, prototypes, as well as high volume components.

Cast polyurethane is an ideal material for constructing parts that require tough physical properties and superior impact resistance.

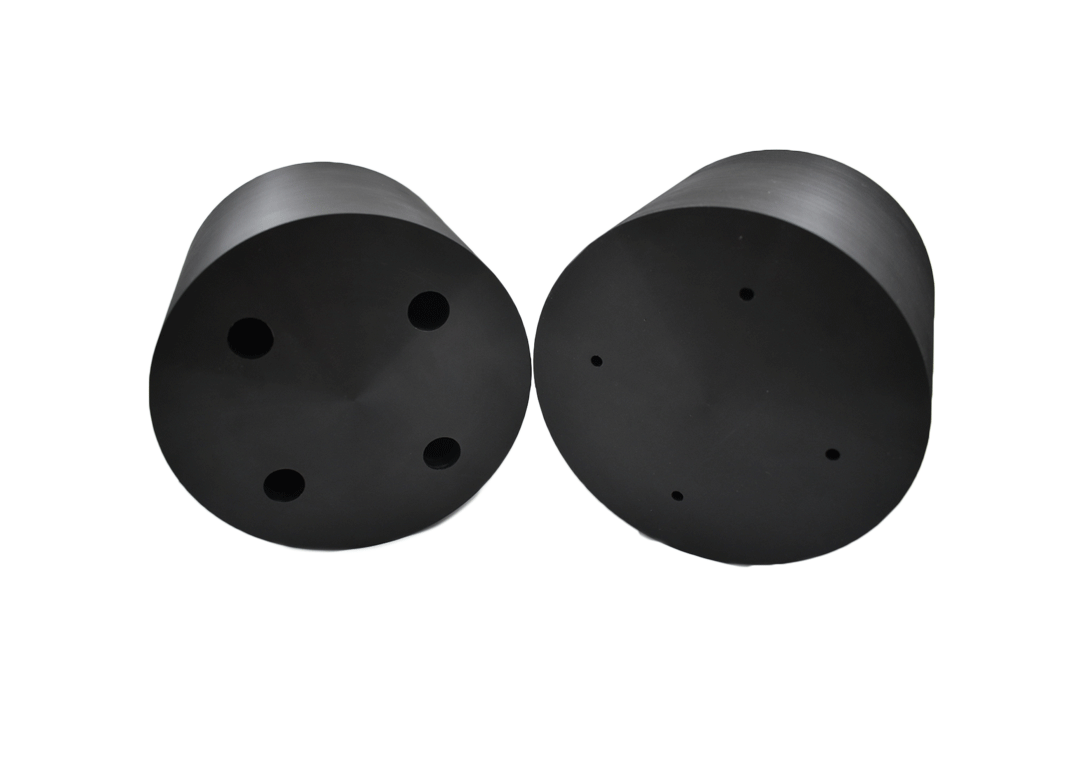

Bonding and Recovery

We have the capability to bond our polyurethane to metal and many other substrates. If you have rollers or wheels that need to be recovered, we can strip off the old material and recover them with the polyurethane formulation that best fits the application. That is a cost-saving for many customers, especially when the cores or inserts are intricate or costly.

Multi Durometer Urethanes

PSI Urethanes offers multi durometer urethane products for complex applications that may require multiple levels of hardness in a single component. Our open casting process gives us the ability to layer two or more durometers in a single urethane sheet or custom part.

Multi durometer products combine characteristics from differently formulated cast urethanes into a single product by layering durometer to adjust features including impact resistance, abrasion resistance, vibration dampening, and co-efficient of friction. Urethane products can be produced with multiple colors as well to be used as wear indicators in highly abrasive applications. Custom urethane parts, sheeting, rings, gaskets, rollers, and bushings are just some of the items that can be designed with multiple durometers.

Some applications of multi durometer urethanes include the following:

- Multi durometer urethane rollers and tubes – Dual durometer rollers and wheels allow for a core to be made of a rigid urethane while the outer diameter can be made of a softer urethane. This removes the need to source aluminum or steel cores, leading to cost savings in materials and processing.

- Multi durometer urethane seals and gaskets - Dual durometer seals can be utilized in applications that require vibration dampening or shock absorption without having to sacrifice abrasion or wear resistance.

- Multi durometer urethane sheets - Dual durometer cutting pads and sheets can be produced so that one side has a tacky, higher grip surface while the harder cutting surface side can remain uncompromised.

Our technical representatives and design staff will work closely with you to meet your specifications – from concept to prototype to production. PSI has spent over 50 years setting the industry standard in custom urethane products, staying on the cutting edge of advances in new materials, designs, and processing technologies.

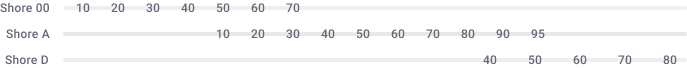

Standard and Custom Durometer Hardness

Here is a list of our standard durometer specifications and our technical brief, to assist you with choosing the correct material.

DUROMETER REFERENCE CALCULATOR

For reference, this hardness is as soft as a Gel Shoe Insole

For reference, this hardness is as soft as a Rubber Band

For reference, this hardness is as soft as a Pencil Eraser

For reference, this hardness is as soft as a Tire Tread

For reference, this hardness is as soft as a Shopping Cart Wheel

For reference, this hardness is as soft as a Hard Hat

Custom Applications

Mounts

Most simply defined, a mount fixes an object in its operating position. Mounts help prevent the transfer of noise, vibration, and movement from one piece of machinery to another

Learn More

Isolators

Urethane isolators, with their shock-absorbing ability, work to extend the life and effectiveness of machinery and its internal components while improving work environments by limiting harmful vibration…

Learn More

Cutting Surfaces

Urethane sheeting is the preferred material for covering the cutting surfaces of work benches, table tops, and more in the manufacturing and food industries.

Learn More

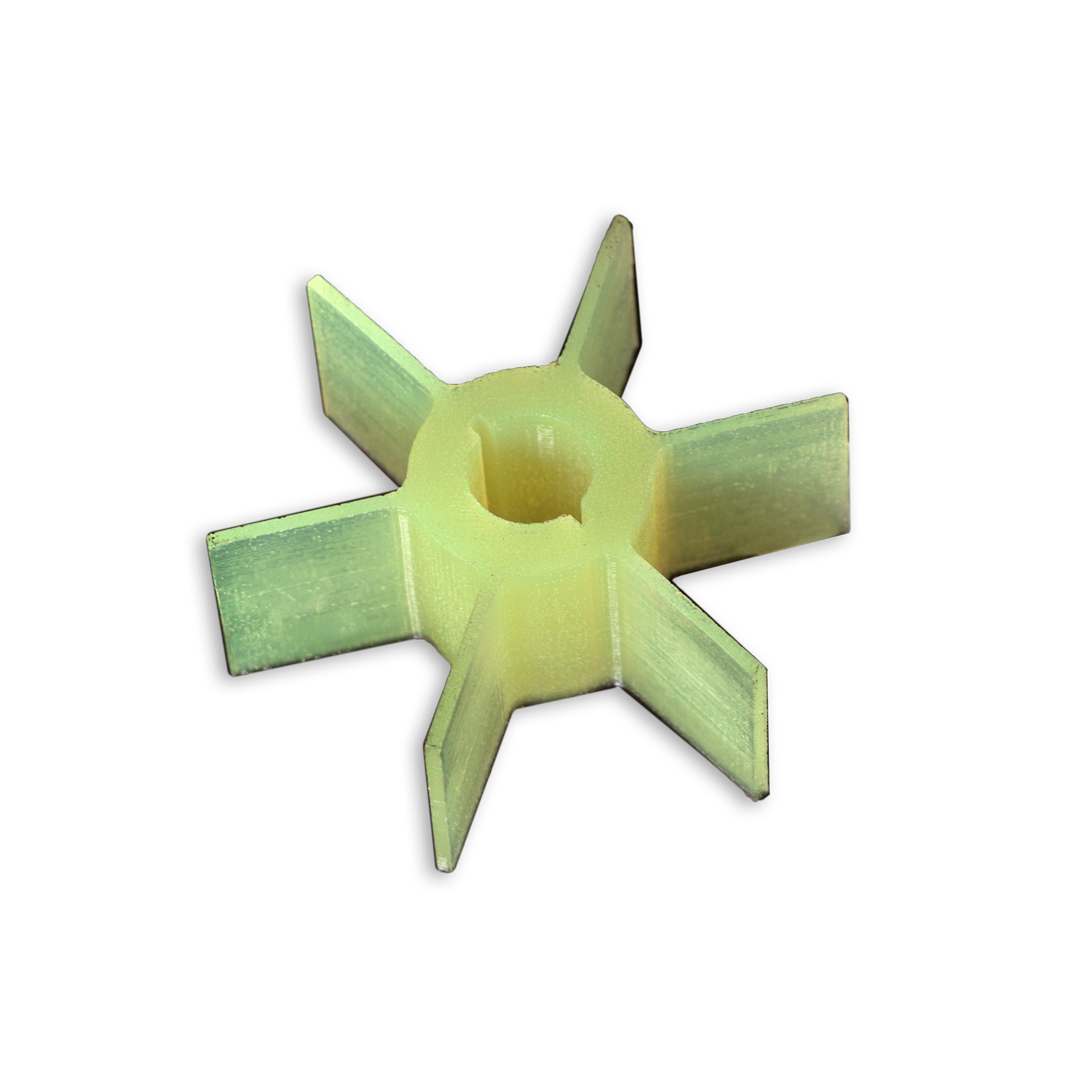

Impellers

Impellers are an essential component in the operation of many forms of machinery—both big and small.

Learn More

Springs

Springs are simple, but beautifully complex when it comes to their versatility and usefulness.

Learn MoreRecommended Reads

The Custom Urethane Provider Checklist - Part 1

How can you ensure that a custom urethane provider is able to meet your needs? Here is a handy checklist of specific qualifications to look for when evaluating…

Custom Urethane Parts/Products: What to Tell Your Supplier – Part 2

In the custom part/product design and formulation process it is important to communicate critical background and functionality information upfront to your supplier.

Custom Urethane Formulations for Custom Needs

When creating a custom urethane part, it is important that a custom urethane formulation is developed and designed as precisely as possible to ensure successful…

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.