Polyurethane Pads

What makes polyurethane pads suitable for various uses?

Urethane pads are used in a variety of industrial applications because they can be formulated to meet specific properties. Polyurethane pads can be utilized in their flat state in applications such as table tops, cutting pads, protective covers and liners. Die cutters, waterjet cutters and machine shops can convert these flat urethane pads into simple gaskets, rings, seals, scrapper blades or an array of other custom parts.

PSI Urethanes stocks hand-poured urethane pads as well as urethane sheet stock to meet your various application needs. These are generally in our natural color, standard formulations and in durometers 60A, 70A, 80A and 90A.

Custom Polyurethane Pad Specs

Durometer Hardness

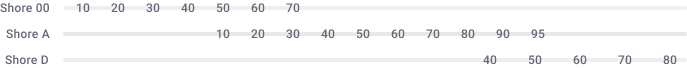

Standard durometers (hardness) range from 60A, 70A, 80A, and 90A. Custom durometers are manufactured in Shore OO scale in 25 OO, 40 OO, 50 OO and 70 OO. In our Shore A scale, 20A to 50A and Shore D scale 50D to 70D.

Looking for a particular durometer specification? Here is a chart with some of our standard formula spec sheets. If you need a different property than what we have listed, please contact us and we will get you taken care of.

Durometer Reference Calculator

For reference, this hardness is as soft as a Gel Shoe Insole

For reference, this hardness is as soft as a Rubber Band

For reference, this hardness is as soft as a Pencil Eraser

For reference, this hardness is as soft as a Tire Tread

For reference, this hardness is as soft as a Shopping Cart Wheel

For reference, this hardness is as soft as a Hard Hat

Custom Formulations

- FDA Dry available in 20A to 85A

- Anti-Static available in 40A to 85A (other durometers may be available upon request)

- Graphite Filled

Thickness Tolerance

Thickness tolerance ±.030” to ± .045” for our open cast poured standard sizes ranging from 12 x 12 to 48 x 120.

Sizes

Polyurethane pads can be produced in custom sizes from .375" x .375" x 25" up to 18″ in thickness, 55″ in width, and 138″ in length.

Available Colors

Large variety of color choices:

- Natural

- Black

- Red

- Blue

- Dark blue

- Green

- Orange

- Yellow

- Peach

- Brown

- Gray

- White

- Custom colors available upon request.

Additional Specs

- Dual Durometers for Specialty Applications

- Seamed sheets can be custom manufactured for larger sizes and still maintain tight tolerances when seamed together.

Benefits of Polyurethane Pads

Many industries prefer urethane cutting surfaces over plastic, glass, or metal. Here is an example of the benefits of using polyurethane pads versus plastic:

Self-Sealing

Polyurethane pads prevent cutting blade deflection from scarred working surfaces or from following previous cut marks.

Custom Sizes

Only purchase what you need to save money and reduce waste.

Easy to Clean

Polyurethane cutting surfaces are easy to wipe down and both sides of the pad can be utilized.

Food Safe

Polyurethane pads can be manufactured in FDA approved formulas for wet and dry food applications.

Durable

Polyurethane has a greater abrasion and tear strength than rubber and is resistant to many chemicals, acids and bases.

Savings

Depending on durometer and thickness, die cutting and/or waterjet cutting is an option to save on mold cost for individual parts.

Durometer & Formulations

When determining what durometer and formulation is right for your product, there are a variety of factors that should be considered. Some examples are:

- Product environment (temperature and/or chemical exposure)

- Does your part need to have grip or be slippery?

- Will your part need to support a certain amount of weight?

- Does it need to be flexible?

- Is there frequent impact?

Defining Your Custom Formulation Needs:

To define your custom formulation needs, the first and most important step is gaining a full understanding of the application in which the part or product will be used in. This usually involves detailed sketches and designs, an understanding of the product environment and much more. Once the full picture of the application has been realized, you can turn to our experts in urethane formulation for strategic guidance and to help identify the optimal formula needed. Doing this will not only ensure you create the strongest, toughest and most durable custom urethane pads to meet your application needs, but will ensure you develop the most cost-effective formulation to achieve your goals.

Polyurethane Pads Applications

Polyurethane Gaskets & Seals

Urethane is a preferred material for gaskets/seals, due to its unwavering strength and durability. It can outperform plastic, rubber, and even steel when faced with environmental factors like oil, acid, and many chemicals. It also has a markedly higher load-bearing capacity than conventional rubber, which is an important characteristic to have for applications that are inherently high-stress and/or a high-load. To do their job effectively, gaskets must create a reliable seal, even under heavy vibration and intense pressure.

PSI Urethanes can tailor-make precision cast urethane gaskets to meet the specifications of your industry or its environment. Almost every detail can be customized, including the tooling, durometer, and color. With a diverse range of formulations, our cast urethane can be manufactured to meet FDA wet or dry food application requirements.

Marine Applications

In offshore applications, advantages to urethane elastomers include their resistance to hydrosis and microbial attack, as well as their reliable performance at low ocean temperatures and high pressure in deep water. They can be used to reduce strain on pipes and cables by flexing in the marine environment, and are suitable for encapsulating electrical components, and for protecting pipes and cables.

Table Tops

Urethane is ideal for table tops because it can be formulated for your specific needs including abrasion resistance, shock absorption, or FDA compliance.

Urethane is not brittle like most plastics and will maintain its strength and impact resistance over a range of durometers (hardness’s). It will provide you with increased noise reduction and material rebound.

Liners for Conveyor Equipment

Urethane liners can bring new life to your operation. These linings protect equipment from prolonged wear and urethane in particular, offers the best abrasion resistance the industry has to offer. Urethane is chemical resistant and can be bonded to metal to provide additional stiffness. It is great for the transport or movement of sticky materials. With urethane, the dirt or sludge rolls off easily.

Bumpers

Urethane bumpers are ideal for applications that require excellent rebound, due to repetitive movement. Abrasion resistance may also be a factor in situations such as conveyor systems or chute liners.

Industries we serve

Many industries rely on polyurethane pads for their needs, including:

Food Processing

PSI manufactures FDA approved urethane products for food processing applications.…

Metal Forming

PSI Urethanes is a leading manufacturer of cast urethane for metal forming press…

Military

We manufacture custom molded parts, polyurethane sheets, and bond to metal for the…

Die Cutting

Our quality and accuracy in keeping close tolerances make our company sought out…

Fluid Cell Remold

For industries that depend on highly complex parts to keep their equipment functioning,…

OEM's

Original Equipment Manufacturers (OEMs) utilize PSI Urethanes’ manufacturing expertise…

Marine

PSI Urethanes is a leading manufacturer of cast and molded urethane for the marine…

Process Automation

From rollers and bumpers to assembly systems and material handling, urethane is a…

Automotive

PSI Urethanes is a leading manufacturer of cast and molded urethane for the automotive…

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.