Have you been searching for custom urethane products but are not quite sure what the ‘durometer’ (also known as ‘hardness’) you need for your specific application(s)? Do you wish there was an easier way to understand the various durometers available? Don’t worry. You are not alone, and fortunately, we’ve got the answer.

The Shore Hardness or durometer of urethane, the measurement of its hardness and the range at which it can be produced, is extremely versatile. Whether you are looking for products that are soft as a marshmallow or hard as a bowling ball, PSI Urethanes can formulate in a large range of durometers offering customers a variety of choices that best suit their urethane product needs.

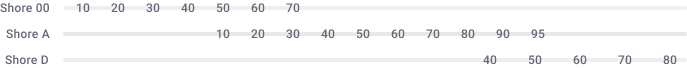

In order to determine the ideal durometer needed, it is important to understand the basics of the Shore Hardness Scale (Shore OO, Shore A, and Shore D) – a standard method of measuring hardness – and the types of materials that fall under each durometer scale.