Cast Polyurethane Couplings

Less Maintenance, Better Performance & Easy Installation

In their simplest form, couplings connect two shafts together at their ends, prevent the shafts from disconnecting during operation, and transmit power between the two. Their main goal is to join two pieces of rotating equipment, all while permitting movement despite some misalignment.

PSI manufactures many types, styles, and material compositions of polyurethane flexible couplings. We take into consideration the conditions under which your coupling will be used including the torsional stiffness, horsepower, shaft misalignment, backlash, and rotational velocity, the degree of lateral, axial, or torsional flexibility your application requires, and more when designing the coupling that meets the needs of your equipment.

Coupling designs and compositions vary greatly in order to satisfy different application criteria.

Available Custom Urethane Coupling Specs

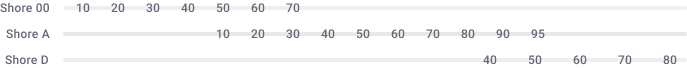

Durometer Hardness

- 20 Shore A to 90 Shore A

- 50 Shore D to 70 Shore D

Here is a list of our standard durometer specifications and our technical brief, to assist you with choosing the correct material.

Durometer Reference Calculator

For reference, this hardness is as soft as a Gel Shoe Insole

For reference, this hardness is as soft as a Rubber Band

For reference, this hardness is as soft as a Pencil Eraser

For reference, this hardness is as soft as a Tire Tread

For reference, this hardness is as soft as a Shopping Cart Wheel

For reference, this hardness is as soft as a Hard Hat

Benefits of Polyurethane Couplings

Wear resistant urethane couplings are an essential part of the equipment that functions under harsh environments. They are specially designed to transmit torque from one shaft to another when two shafts are misaligned.

In general, they help to dampen shock loads and vibration, prevent metal on metal contact, and lead to clean, quiet machine performance. Some, however, can be sensitive to chemicals and high temperatures, and they are not torsionally stiff enough for positive displacement.

Flexible Coupling Applications

Urethane is an elastomeric coupling material with resilience, elasticity and has the best damping capabilities. Urethane is the optimal elastomeric choice for applications that require high torque in confined spaces, or those that require resistance to atmospheric elements like ozone, sunlight, and hydrolysis. They are impact, oil, chemical, and abrasion-resistant. The teeth of a urethane coupling flex to account for misalignment, yet are rigid enough to perform in almost any application.

Flexible urethane couplings are used in many industrial equipment applications. They’re used to join drive shafts to driven shafts, motors to pumps, gear boxes to driven equipment, motors to gearboxes, and internal combustion engine flywheels to pumps, transmissions, blowers, and more.

Call PSI For Your Flexible Urethane Coupling Needs

Call one of our experienced urethane professionals at (800) 888-5156 for design assistance and to get help selecting the right flexible coupling for your equipment. You can also conveniently request a quote for any size project online, at any time.

Flexible Coupling Types

Couplings can be either flexible or rigid (elastomeric or metallic). There are many types of coupling designs including jaw couplings, donut couplings, pin and bush couplings, grid couplings, gear couplings, chain couplings, tire couplings, and more.

Within the flexible coupling world, couplings can be further broken down into three major types:

Compression Loaded

With compression type elastomeric couplings, the driving and driven hubs rotate in the same plane. Parts of the driving hub push parts of the driven hub through elastomeric elements that act as cushions between them. These cushions are not attached to either hub. As torque is transmitted, the coupling is compressed.

Compression type couplings have a higher load capacity in compression than shear, and can transmit higher torque and tolerate greater overload.

Shear Loaded

With shear type elastomeric couplings, the driving and driven hubs rotate in different planes. The driving hub pulls the driven hub through an elastomeric element, which is attached to both hubs. As torque is transmitted, the elastomeric element absorbs some of the torque by being stretched through twisting.

Shear type couplings can account for more parallel and angular offset than compression type couplings, plus they offer a greater degree of torsional softness.

Torsional

Torsional elastomeric couplings dampen torsional vibrations. They are most commonly used in mechanical power transmission systems, and more commonly in diesel engine applications. They “tune” the system above or below its natural frequencies.

Industries Utilizing Urethane Couplings

Many industries rely on urethane couplings for their needs, including:

Food Processing

PSI manufactures FDA approved urethane products for food processing applications.…

Metal Forming

PSI Urethanes is a leading manufacturer of cast urethane for metal forming press…

Military

We manufacture custom molded parts, polyurethane sheets, and bond to metal for the…

Die Cutting

Our quality and accuracy in keeping close tolerances make our company sought out…

Fluid Cell Remold

For industries that depend on highly complex parts to keep their equipment functioning,…

OEM's

Original Equipment Manufacturers (OEMs) utilize PSI Urethanes’ manufacturing expertise…

Marine

PSI Urethanes is a leading manufacturer of cast and molded urethane for the marine…

Process Automation

From rollers and bumpers to assembly systems and material handling, urethane is a…

Automotive

PSI Urethanes is a leading manufacturer of cast and molded urethane for the automotive…

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.