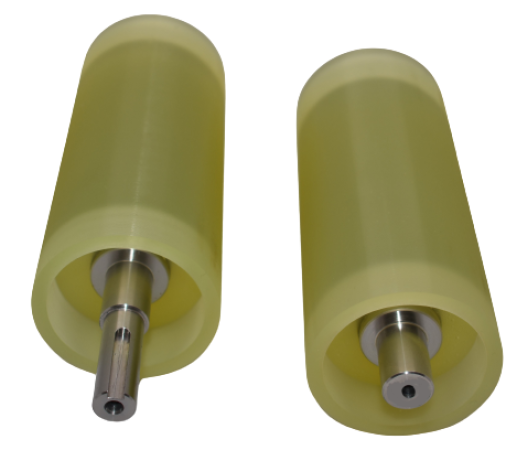

Cast Urethane Rollers

Custom Polyurethane Rollers For Your Applications

PSI’s standard and custom made urethane formulations are wear and generally cut-resistant, can carry up to four times higher load than rubber, and stand up to harsh environments. That makes PSI’s urethane rollers the perfect solution for high-stress applications, such as load wheels, conveyors, and pulleys.

Recover Your Existing Metal Cores

In addition to manufacturing new wheels/rollers, we also have the ability to recover your existing metal cores. No matter what material you currently have on your rollers, we've got you covered. All you need to do is give us a durometer(hardness) and what profile you need. Let PSI show you how we can offer you substantial savings by not having to replace your cores.

Our staff can assist you with urethane roller formulation selection in order to maximize their longevity and productivity.

Cast Urethane & Polyurethane Roller Specs

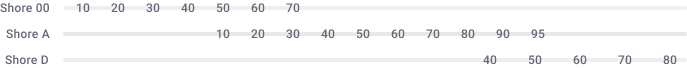

Durometer Hardness

- 25 Shore OO

- 40 Shore OO

- 50 Shore OO

- 70 Shore OO

- 20 Shore A to 90 Shore A

- 50 Shore D to 70 Shore D

Here is a list of our standard durometer specifications and our technical brief, to assist you with choosing the correct material.

DUROMETER REFERENCE CALCULATOR

For reference, this hardness is as soft as a Gel Shoe Insole

For reference, this hardness is as soft as a Rubber Band

For reference, this hardness is as soft as a Pencil Eraser

For reference, this hardness is as soft as a Tire Tread

For reference, this hardness is as soft as a Shopping Cart Wheel

For reference, this hardness is as soft as a Hard Hat

Application Specific Formulations

- Dual Durometers

- FDA Dry Food Approved 40A to 85A

- Static Dissipative material is available in 40A to 85A (other durometers may be available upon request)

Benefits of Polyurethane Rollers

- Marring of products - Polyurethane with pigment or in its natural state, does not mar nor damage any material it comes into contact with. However, rubber has carbon added to it and when it comes into contact with products, it can leave black marks on them. Additionally, metal is very hard and will not only mar objects, but it can also damage them.

- Chemical/Water Resistance - Polyurethane outperforms rubber in applications that are either submerged or exposed to wet environments for a long period of time, where rubber would rot over time or metal may corrode.

- Abrasion Resistance - Polyurethane has excellent abrasion and wear resistance properties, resulting in fewer instances of needing replaced. In instances where rollers experience a great deal of abrasion from combining dynamic loads and high friction, polyurethane surpasses natural rubber. For these reasons, urethane is best for conveyor, driving and printing rollers.

- Low Permanent Set - Rebound is essential for printing, driving and coveyor rollers. Polyurethane can be manufactured to handle your heavy items and not take a set.

- Tensile Strength & Elongation- Polyurethane has the ability to handle more pounds per square inch than rubber without rupturing and breaking apart. This is especially beneficial for driving and conveyor rollers when systems are running fast and carrying a great deal of weight.

- Wide range of formulations/durometers - Polyurethane can be manufactured to your specific requirements. Whether you need FDA approved wet or dry formulations or specific durometers for grip or strength, urethane can be formulated to give you the best wear for your specific application.

- Wide range of colors available - Our polyurethane rollers come in a wide range of colors to suit your specific application and requirements. Black and Red are recommended for applications that require UV resistance. Custom colors can be produced upon request for a large volume order.

What Are Types of Urethane Rollers?

Polyurethane has excellent bonding abilities. Our high quality bonding agent allows for a superior bond, especially to metal cores. Various other materials may be substituted for cores, however will vary depending on size, shape and type of substrate. Some rollers are 100% urethane, called sleeves and are slipped over a core or have bearings popped into the ends.

PSI produces a wide range of polyurethane roller and polyurethane roller covering types including:

- Step and Plunge Rollers

- Flat Taper Rollers

- Chevron Rollers

- Multiple Crown Rollers

- Hourglass Rollers

- Conveyor Rollers

- Drive Rollers/Wheels

- V-Rollers

- Nip Rollers

- Idler Rollers

- Feed Rollers

- Pulleys

- Wringer Rollers

- Custom Shaped Urethane Rollers

Rollers Guide:

Step and Plunge Rollers – Urethane step rollers are designed with recesses or grooves to help guide a track or lift.

Flat Taper Rollers - Flat tapered urethane rollers leverage multiple flat surfaces for material transport. Depending on the application a full or partial taper can be provided.

Chevron Rollers – Polyurethane chevron rollers are produced with a recessed or raised V shaped pattern.

Multiple Crown Rollers – Multi crown urethane rollers work by steering a conveyor belt to the center of the roller and aid with belt tracking.

Hourglass Rollers – Urethane hourglass rollers are utilized in applications where materials are center aligned and vibration resistance is critical.

Conveyor Rollers – Urethane conveyor rollers or sleeves are non-power-driven rollers attached to axles that allow material to roll along a fixed path.

Drive Rollers (Wheels) – Polyurethane drive rollers are typically driven by a motor or motors to assist in the material handling process.

V-Rollers – Urethane V-Rollers are designed to limit movement like side-to-side drift to allow for a more precise center guided material handling line.

Nip Rollers – Urethane nip rollers are used to press and feed material simultaneously, commonly resulting in a pressed sheeting or laminated product.

Idler Rollers – Urethane idler rollers main function is to support the conveyor and conveyor belting along its full length.

Feed Rollers – Urethane feed rollers transport or feed material from a location to either a machine for processing or another location in the production process.

Pulleys – Urethane pulleys are designed for high load bearing applications where the fixed point will need to resist compression while supporting movement.

Wringer Rollers – Urethane wringer rollers are designed to be used in wet applications in which excess liquid must be pulled from a material.

Custom Shaped Urethane Rollers – Urethane rollers with custom shapes, sizes, colors, and surface finish options are available upon request. Contact us today to discuss your custom roller needs.

Call PSI for a Custom Quote

Call one of our experienced application engineers today at (800) 888-5156 to learn more about urethane rollers or request a quote for your custom urethane project online at any time. If possible, please also have available the intended roller load weight, speed, and any environmental elements that may need to be considered as well (like corrosive or abrasive elements).

Custom Urethane Rollers Gallery

Custom polyurethane rollers are made from tough, premium grade urethane, provide reliable performance and are the perfect solution for high-stress applications. Learn more about custom polyurethane rollers.

Industries That Can Use Cast Urethane Rollers

Many industries rely on urethane rollers for their needs. Urethane rollers or wheels are also the choice for woodworking machinery, newspapers and commercial presses, mailroom equipment, metal trades, plastics fabrication, specialty manufacturing, material handling, and medical equipment.

Food Processing

PSI manufactures FDA approved urethane products for food processing applications.…

Metal Forming

PSI Urethanes is a leading manufacturer of cast urethane for metal forming press…

Military

We manufacture custom molded parts, polyurethane sheets, and bond to metal for the…

Die Cutting

Our quality and accuracy in keeping close tolerances make our company sought out…

Fluid Cell Remold

For industries that depend on highly complex parts to keep their equipment functioning,…

OEM's

Original Equipment Manufacturers (OEMs) utilize PSI Urethanes’ manufacturing expertise…

Marine

PSI Urethanes is a leading manufacturer of cast and molded urethane for the marine…

Process Automation

From rollers and bumpers to assembly systems and material handling, urethane is a…

Automotive

PSI Urethanes is a leading manufacturer of cast and molded urethane for the automotive…

Recommended Reads

Polyurethane VS Rubber Rollers

When it comes to choosing the right material for your industrial roller applications, you may have a lot of questions. If your existing equipment came with rubber...

Custom Cast Urethane Rollers: Time to Re-cover Used Rollers?

There are several reasons that urethane rollers are the go-to choice for many industries including food processing, steel, marine, and packaging, to name a few.…

Understanding Urethane Rollers: Benefits, Types and Applications

Many organizations rely on urethane rollers for a variety of applications. Rollers made of urethane are wear resistant and can carry higher ...

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.