Cast Polyurethane Gaskets

The Ideal Choice for High-Stress, High-Load Applications

Many industries make use of gaskets within their engine technology and manufacturing processes, including the food processing, automotive, aerospace, electronics, and military sectors. Though simple in appearance, gaskets play an essential role in an innumerable number of applications.

PSI manufactures gaskets from the highest-quality urethane resins available. We cut gaskets from precision urethane sheets that are 38.5” x 122.5”, can hold close tolerances of ± .005 on material from .020 to .125 and ± .010 up to .375, and are available in any color and durometer (or hardness). We also offer custom molded or machined gaskets from tubing. This allows us to meet the customization needs of nearly any gasket application.

Custom cast polyurethane gaskets, cut from precision cast sheet material, can be manufactured at PSI without the use of wax or a mold release.

Custom Urethane Gasket Specs

Durometer Hardness

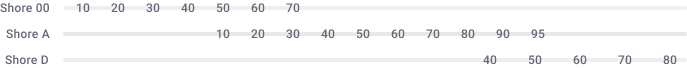

- 25 Shore OO

- 40 Shore OO

- 50 Shore OO

- 70 Shore OO

- 20 Shore A to 90 Shore A

- 50 Shore D to 70 Shore D

Here is a list of our standard durometer specifications and our technical brief, to assist you with choosing the correct material.

Durometer Reference Calculator

For reference, this hardness is as soft as a Gel Shoe Insole

For reference, this hardness is as soft as a Rubber Band

For reference, this hardness is as soft as a Pencil Eraser

For reference, this hardness is as soft as a Tire Tread

For reference, this hardness is as soft as a Shopping Cart Wheel

For reference, this hardness is as soft as a Hard Hat

Size

Precision cast sheet material can be produced in thicknesses of .010" to .375" x 38.5 x 122.5 and are an excellent choice for tight tolerance seals to be waterjet cut or die cut from. We also have a wide range of ID/OD tubes that can be machined and parted to fit your requirements. Both of these options are great alternatives to making molds, however if neither of those options fulfill your needs, we also have the capability to provide molded product.

Thickness Tolerance

You can select a thickness tolerance as close as to ±0.001″, with ±.005″ to ±.010" on our precision cast sheeting being standard. For machined and parted tubes or molded parts, please let your sales person know what your requirements are and we will quote you accordingly.

Available Colors

Choose our natural honey amber color or from one of our other standard colors of black, brown, orange, yellow, red, green, peach, white, sky blue and royal blue.

Wax Options

In the event that your gasket needs to have a pressure sensitive adhesive backing, precision cast sheets can also be manufactured without the use of any wax or mold release. You can choose from having no wax on one or both sides, depending on your needs.

Application Specific Formulas

PSI Urethane's carries a wide range of resins and curatives, that can be combined to give your part the longest life possible.

- Ether formulas are best for any water involved application.

- Esters are more solvent resistant. Some are more resistant than others, so be sure to let your sales person know what solvent you are using.

- FDA compliant formulations are available in a wide range of durometers(hardness).

What are the Benefits of Urethane Gaskets?

Abrasion Resistant & Higher Load Bearing Capacity

Urethane is the toughest, most abrasion-resistant of all elastomeric materials. Urethane is a preferred material for gaskets due to its unwavering strength and durability. It can outperform plastic, rubber, and even steel when faced with environmental factors like oil, acid, and many chemicals. A poor quality or ill-fitting gasket, however, could cause chronic leaks or failures, resulting in a catastrophic impact on a product or process.

Highly Flexible In A Variety Of Temperatures

Polyurethane gaskets are well-known for their ability to conform to the shape of their application, withstand changing weather conditions, and remain flexible in within certain temperature changes. Urethane, depending on the formula, will remain flexible down to -90°F and can withstand temperatures of up to 250°F, though it may soften before that point and lose load-bearing capacity; urethane can withstand intermittently higher temperatures.

Call PSI for a Custom Quote

Call one of our experienced application engineers today at (800) 888-5156 to learn more about urethane gaskets or request a quote for your custom urethane project online at any time.

What Are Urethane Gaskets?

Gaskets create a pressure-tight seal between two or more stationary parts. This seal prevents gas, dirt, dust, or fluid from leaking and is flexible enough to fill any physical irregularities between the surfaces being sealed. Proper cast urethane seals will prevent leakage during temperature and pressure changes, regardless of intensity. Some gaskets can even withstand electrical or electromagnetic forces. They can be designed in the form of a ring or sheet, and can be manufactured in numerous designs and from numerous materials, including metal, rubber, silicone, cork, foam, or a combination of materials. The material and design of the gasket will vary based on the application.

Industries Utilizing Urethane Gaskets

Many industries rely on urethane gaskets for their needs, including:

Food Processing

PSI manufactures FDA approved urethane products for food processing applications.…

Metal Forming

PSI Urethanes is a leading manufacturer of cast urethane for metal forming press…

Military

We manufacture custom molded parts, polyurethane sheets, and bond to metal for the…

Die Cutting

Our quality and accuracy in keeping close tolerances make our company sought out…

Fluid Cell Remold

For industries that depend on highly complex parts to keep their equipment functioning,…

OEM's

Original Equipment Manufacturers (OEMs) utilize PSI Urethanes’ manufacturing expertise…

Marine

PSI Urethanes is a leading manufacturer of cast and molded urethane for the marine…

Process Automation

From rollers and bumpers to assembly systems and material handling, urethane is a…

Automotive

PSI Urethanes is a leading manufacturer of cast and molded urethane for the automotive…

Recommended Reads

Advantages to Choosing Urethane Gaskets Over Rubber Gaskets

Urethane is the toughest of all elastomeric materials and is the preferred material for gaskets due to its ultra-high strength and durability under pressure..

Precision Cast Urethane Sheets: Top 3 Benefits for Seal and Gasket Cutting Material

Seal and gasket cutters need precision cast material because customers demand it. Seals and gaskets fill the gap between two objects to prevent leakage and act…

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.