Precision Polyurethane Sheets & Sheeting

Precision Cast Sheeting

Urethane is the preferred material for parts that need to perform reliably and endure intense applications. Overall, urethane is tough and versatile, with properties that deliver high cut resistance, low compression set, superior elongation, and tensile strength.

What makes precision cast sheets suitable for various uses, is that it comes in various forms

- Custom formulations to accentuate your particular physical property specifications.

- Larger sized sheets can be custom manufactured and still maintain tight tolerances when seamed together.

- Sheets can be produced without mold release on one side or both sides. This is a necessity if you are adhering the material to a substrate or if you are applying a PSA backing.

Precision Urethane Sheets & Sheeting Specs

Durometer Hardness

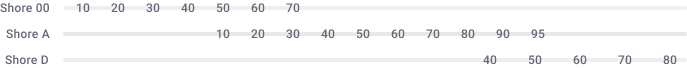

Precision cast sheets are available in 20 Shore A to 50 Shore D durometer for any thickness between .010″ to .375″ thick. In 60 Shore D to 70 Shore D, available in any thickness between .010″ to .125″ thick. If your application requires 25, 40, 50 or 70 Shore OO, we can manufacture thicknesses of .063” to .250”.

From 25 Shore OO – 70 Shore OO, 20A to 95A, 50D – 70D

Here is a list of our standard durometer specifications and our technical brief, to assist you with choosing the correct material.

Durometer Reference Calculator

For reference, this hardness is as soft as a Gel Shoe Insole

For reference, this hardness is as soft as a Rubber Band

For reference, this hardness is as soft as a Pencil Eraser

For reference, this hardness is as soft as a Tire Tread

For reference, this hardness is as soft as a Shopping Cart Wheel

For reference, this hardness is as soft as a Hard Hat

Thickness And Tolerance

Thickness can be adjusted to meet you requirements from .005" to .375". Sheets from .005" to .125" have a standard tolerance of ±.005. Sheet thickness of .188" to .375", have a standard thickness tolerance of ±.010.

Standard thickness tolerance sheets of ±.005 can be manufactured as close as ± .001 and ±.010 can be manufactured as close ±.005 upon request.

Custom Formulations

- FDA Dry available 20A to 90A

- FDA Wet available 40A to 90A

- Anti-Static available in 40A to 85A; 55D & 60D

- Dual Durometers - Multiple layer's available for custom applications

Colors

Large variety of color choices:

- Natural

- Black

- Red

- Blue

- Dark blue

- Green

- Orange

- Yellow

- Peach

- Brown

- Gray

- White

Benefits of Precision Urethane Sheeting

Many industries prefer urethane cutting surfaces over plastic, glass, or metal. Here is an example of the benefits of using urethane sheets versus plastic:

- Self-Healing

Urethane sheeting prevents cutting blade deflection from scarring working surfaces. It also helps prevent a work surface from flaking or chipping. - Food Safe

FDA approved sheeting for both wet or dry food applications (ideal for industrial kitchens, meat packing facilities and various types of food packaging facilities). - Abrasion and Tear Resistant

Urethane has greater abrasion and tear strength than plastic. - Customizable

Urethane can be manufactured in a variety of thickness tolerances, durometers, and formulations. - Memory

Urethane can be stretched and will return to its original state, where plastic can be stretched past the point of being able to return. - Non-brittle

Unlike Plastic, urethane is an elastomer and it will not crack under impact.

Precision Urethane Sheeting Applications

- Cutting surface

- Protective curtains

- Gaskets

- Windows

- Chute liners

- Conveyor skirting

- Flapper doors

The New Standard in Tight Tolerances

In 1996, PSI dramatically improved the precision cast urethane sheet process, thereby establishing a new industry standard in thickness tolerances. Today all of our urethane sheets 1/8″ or less meet a thickness tolerance of ±.005″. When requested, PSI offers tolerances as close as ±.001″. PSI also offers custom thickness (.005″ to .375″), durometer (25 Shore OO to 70 Shore D), and our full-size polyurethane sheets are available in a variety of colors.

| Sheet Thickness | Full Sheet 38.5″ x 122.5″ | Half Sheet 38.5″ x 61.25″ | ||

| 60-80A | 90A | 60-80A | 90A | |

| .005″ | call | call | ||

| .02″ | ✓ | ✓ | ||

| .031″ | ✓ | ✓ | ✓ | ✓ |

| .063″ | ✓ | ✓ | ✓ | ✓ |

| .094″ | ✓ | ✓ | ✓ | ✓ |

| .125″ | ✓ | ✓ | ✓ | ✓ |

| .188″ | ✓ | ✓ | ✓ | ✓ |

| .25″ | ✓ | ✓ | ✓ | ✓ |

| .313″ | ✓ | ✓ | ||

| .375″ | ✓ | ✓ |

Industries we serve

Many industries rely on precision urethane sheet and sheeting for their needs, including:

Food Processing

PSI manufactures FDA approved urethane products for food processing applications.…

Metal Forming

PSI Urethanes is a leading manufacturer of cast urethane for metal forming press…

Military

We manufacture custom molded parts, polyurethane sheets, and bond to metal for the…

Die Cutting

Our quality and accuracy in keeping close tolerances make our company sought out…

Fluid Cell Remold

For industries that depend on highly complex parts to keep their equipment functioning,…

OEM's

Original Equipment Manufacturers (OEMs) utilize PSI Urethanes’ manufacturing expertise…

Marine

PSI Urethanes is a leading manufacturer of cast and molded urethane for the marine…

Process Automation

From rollers and bumpers to assembly systems and material handling, urethane is a…

Recommended Reads

Which Type of Urethane Sheet Do I Need For My Application?

When it comes to shopping for the best urethane sheeting for your application, you can’t go wrong with sheeting from PSI Urethanes..

Precision and Standard Cast Sheeting: What is Best for Your Needs?

When deciding whether precision or standard cast sheeting would work best for you, there are a few things to consider..

Spotlight On Urethane Sheets: Benefits, Industry Use and Choosing a Manufacturer

Urethane sheets are used in a wide range of applications due to their variety in size, durometer (hardness) and thickness..

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.