Bonding Urethane To Metal, PVC And Nylon

Process Of Bonding Urethane

Preparing a core for the bonding process can vary depending on a few things. What type of material the core is made of, is the core clean and new, or does the core need to be stripped of old material. If we are recovering a core, we will first clean the core of all existing material, oil and rust.

No matter what surface we are bonding to, it has to be scuffed up to improve the bond between the core material and the polyurethane. This is a necessary process for the urethane to have an unbreakable bond with the substrate. The primary methods we use to achieve the perfect bonding surface is either sanding or by grit blasting.

The cores are then cleaned of any residue and coated with a bonding agent. For the bond to adhere properly to the core/insert, we place them in a high heat oven and bake it on. We then start the process of molding the polyurethane onto the core.

Benefits Of Bonding Polyurethane To A Substrate

- Non-Scratching – Metal on its own can damage a product by scratching/gauging it, while bonded urethane on the other hand will not.

- Non-Marring – If you have metal encased in rubber, it will leave black marks on the product it comes into contact with, however urethane does not mar/mark.

- Abrasion Resistance – Metal can be coated to help reduce abrasion and friction, however metal will eventually wear out. Urethane can be formulated to your specific abrasion resistance needs. If friction is an issue, we are able to reduce it with additives such as molly or graphite.

- Strength – Urethane is an elastomer, which means it is resilient and non-brittle.

- Weight and Cost – PVC and nylon are both lite weight, less expensive than metal, and can be used as your core to apply bonded urethane to.

Applications For Bonded Polyurethane

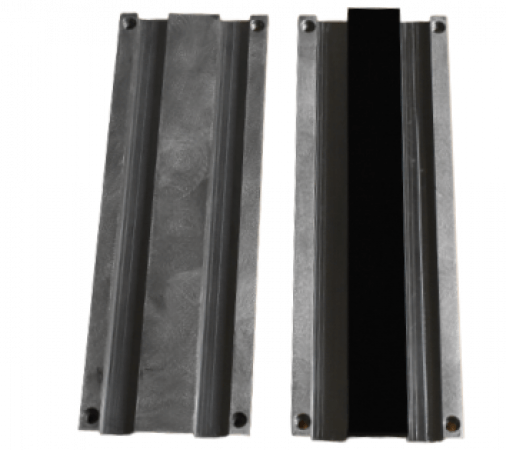

- Metal Forming Tubs

- Concrete Shoes

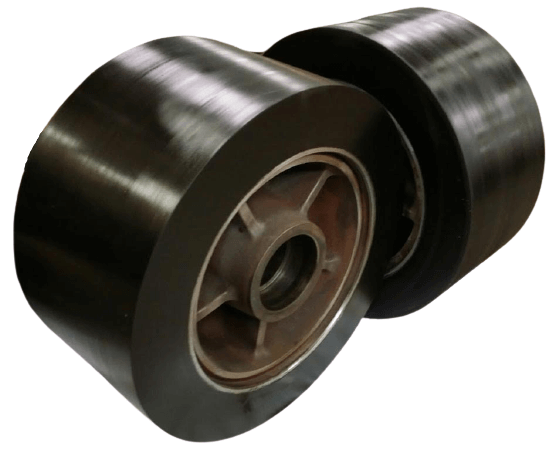

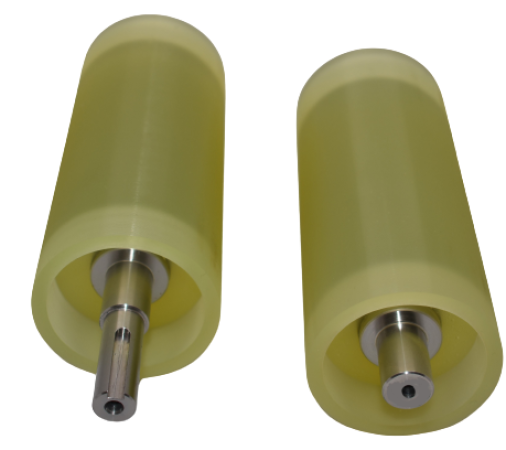

- Rollers/Wheels

- Lined Pipes

- Fluid Cells

- Tumbler Barrel Liners

Bonded Urethane Gallery

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.

Recommended Reads

In addition to manufacturing new wheels/rollers, we also have the ability to recover your existing metal cores. No matter what material you currently have on…

One of the top four reasons urethane is requested in industrial applications is due to its abrasion resistant properties. When severe wear is a concern, polyurethane…

As a manufacturer of custom urethane products, PSI’s experience extends to a wide range of industries and polyurethane applications. We are a trusted manufacturer…