Thermoset vs. Thermoplastic Urethane

The Difference

What is the difference between thermoset urethane and thermoplastic urethane? Both can be used for a wide variety of applications in a variety of fields; however, because of their unique properties, each is best suited for specific applications.

- Thermoset urethane is a polymer that cannot be melted and reformed and is generally more durable than thermoplastic urethane.

- Thermoplastic urethane is a polymer that can be melted and reformed, and is elastic and highly flexible, making it a versatile material suitable for use in a wide range of industries.

Below you will find a breakdown of the properties and applications of thermoset vs. thermoplastic urethane.

Urethane Properties Breakdown

Abrasion Resistance

Abrasion resistance refers to a material’s capacity to resist abrasion during mechanical actions like rubbing or scraping. A high level of abrasion resistance means a material can outwear materials like rubbers, plastics, and metals by greater margins.

- Thermoset urethane has a high resistance to abrasion, as well as a high level of cut resistance.

- Thermoplastic urethane is more likely to tear with abrasive applications.

Heat Resistance

A urethane’s ability to resist heat plays an important role in determining its application.

- Thermoset urethane performs well in temperatures of up to 250° without issue.

- Thermoplastic urethane will soften when tested in high temperatures.

Hardness

The hardness of urethane is measured in a range of durability and varies widely from type to type. In fact, urethane can be incredibly soft or hard, depending on its makeup. The scale includes shore OO, which is used to describe extremely soft materials; shore A, the most common scale, is used primarily to describe rubbers and other varieties of elastomer; and shore D, which is used for harder materials like rigid plastics.

- Thermoset urethane has a wide range of durometers, which are available in both A and D scales.

- Thermoplastic urethane is softer, and available in a very small range in A scale only.

Load Bearing Capacity

Load-bearing capacity refers to a material’s ability to perform under the great weight like high load-bearing wheels, heavy-duty couplings, metal forming pads, shock pads, and machine mounts.

- Thermoset urethane holds a high weight per square inch.

- Thermoplastic urethane holds a low weight per square inch.

Thermoset Polyurethane

Abrasion Resistance

Best for abrasive applications because of its high resistance to abrasion and cutting.

Heat Resistance

Withstands temperatures of up to 250° without problems.

Hardness

Has a wide range of durometers available in A & D scales.

Load Bearing Capacity

Thermoplastic Urethane

Abrasion Resistance

Will tear with abrasive applications.

Heat Resistance

Will soften, deform, and degrade in temperatures above 250°.

Hardness

Has a very small range in “A” scale only.

Load Bearing Capacity

Unable to hold a large amount of weight without destroying the material.

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.

Applications of Thermoset vs. Thermoplastic Urethane

Choosing between thermoset and thermoplastic materials depends heavily on the intended application.

Thermoset Urethane

Best suited for heavy-duty industrial settings and environments requiring high abrasion and heat resistance, thermoset urethane is commonly found in:

- Gaskets and seals

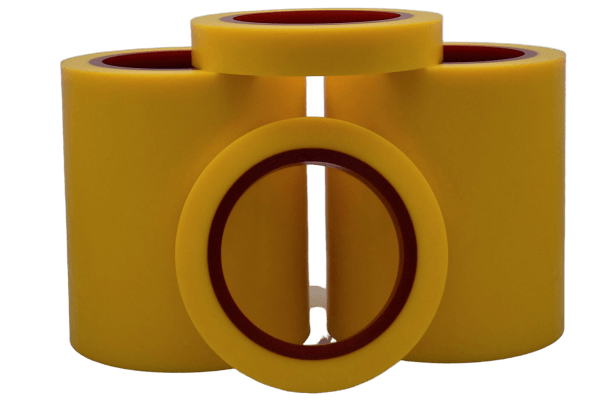

- High-wear rollers

- Heavy load-bearing wheels

Explore more about thermoset urethane in industrial applications on our urethane applications page.

Thermoplastic Urethane Applications

With its elasticity and reusability, thermoplastic urethane shines in settings demanding flexibility and reshaping. Common uses include:

- Flexible tubing

- Lightweight cables

- Automotive parts

Dive deeper into its versatile applications by visiting our page on industries served.

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.

Why Choose PSI Urethanes?

PSI Urethanes specializes in custom solutions tailored to your specific project needs. If you’re considering thermoset polyurethane, our expert team is here to help you find the perfect material for your application.

Learn more about our quality offerings:

Not sure which urethane material suits your project? Contact our experts, and we’ll guide you every step of the way. Request a Quote and start your urethane project with confidence.

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.