Static Dissipative Polyurethane Material

Cast polyurethane elastomers are generally thought of as excellent electrical insulators. The excellent abrasion resistance of polyurethanes is the reason they are generally found in applications such as material handling, where charge accumulation can become an issue.

Applications occasionally require the polyurethane be a non-insulator in order to avoid detrimental or dangerous electrical discharges.

Static Conductive Definitions

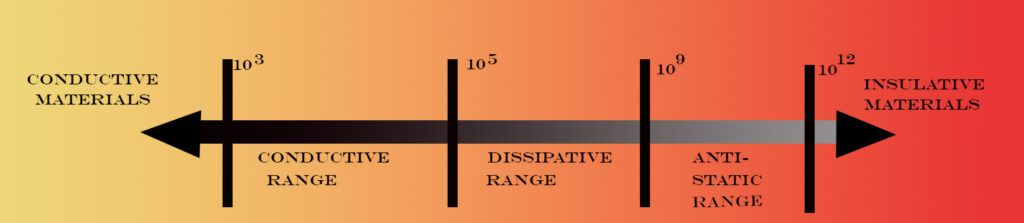

Conductive materials are materials that have a surface resistance of 1 x 105 ohms/square or less.

Static Dissipative materials have a surface resistance of more than 1 x 105 ohms/square but not greater than 1 x 109 ohms/square.

Anti-Static or Resistive materials have a surface resistance of more than 1 x 109 ohms/square but less than 1 x 1012 ohms/squre.

Insulative materials have a surface resistance of greater than 1 x 1012 ohms/square.

How To Achieve Static Conductive Material

1. Metal salts: this creates a top surface that attracts moisuture which makes the top surface good, but the interior of the part may not be as conductive.

2. Carbon Black & Carbon Fiber: both materials require high loading of the filler and can leave marks. The anti-static properties can have hot and cold spots throughout the part.

3. Cataphor: is a reactive chemical that is limited in what formulations and durometers it can produce. In addition, it also lowers the physical properties of the urethane.

4. Carbon Nanotubes: is a non-reactive material that does not change the physical properties of polyurethane, nor does it mark materials it comes into contact with. It should also be noted that in most cases, there is an improvement in physical and mechanical properties. Very small amounts are needed and conductivity is uniform throughout the part, even if it abrades. This is the process that PSI Urethanes integrates into our formulations.

Applications And Industry Use For Static Dissipative Urethane

- Mining

- Electronics

- Explosive Environments

- Business Machines

- Robotics

- Material Storage & Handling Products

- High Speed Production Environments

- Chemical Production

- Munitions Factory

- Wheels for Hand Trucks & Medical Equipment

- Telecommunications

- Automotive Industry

- Pipe linings for Grain Elevators, Transportation & Storage

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.