If you have ever been to a gym, you know there is always that one person who throws their weights to the ground after each set. This is of course to the utter dismay of most patrons trying to raise their heartbeats through cardio and not through getting the fright of their lives.

But have you ever wondered how the poor weights survive such torment?

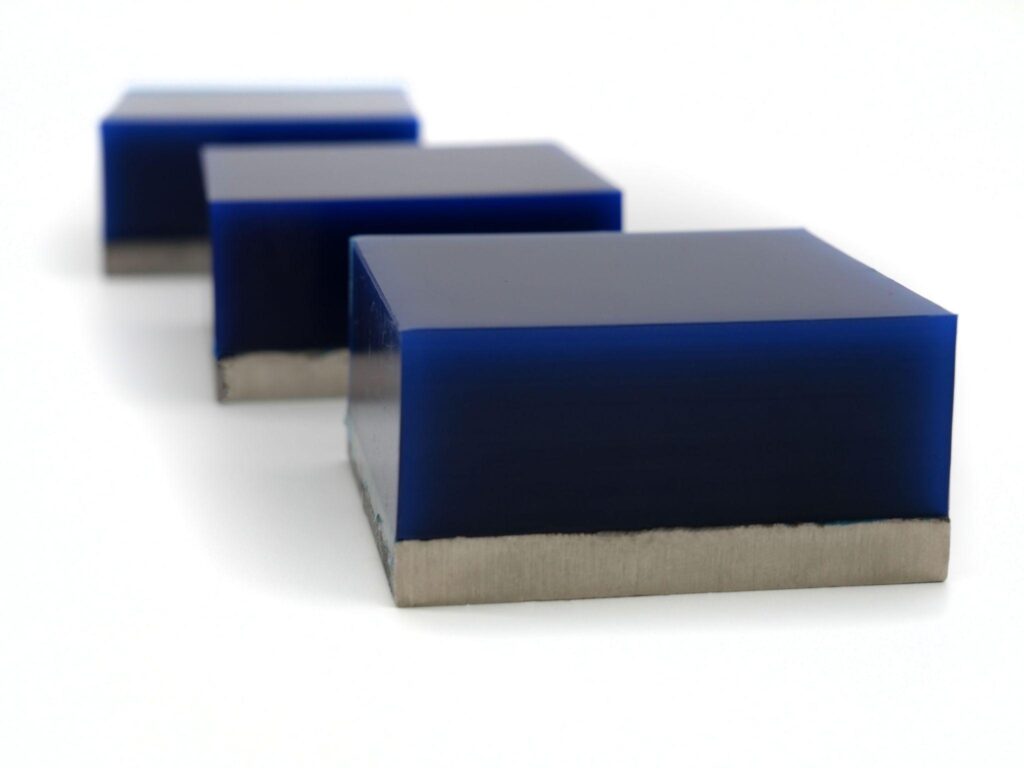

If you look at most gyms that have complete and undamaged weights, you would probably see an external coating of polyurethane lining them. Polyurethane is a durable and flexible plastic material that can absorb impact and resist wear and tear.

This protective layer of polyurethane serves as a polyurethane bumper and its application extends far beyond the gym.

Understanding Polyurethane Bumpers

Polyurethane bumpers are pieces of polyurethane installed on equipment or structures to absorb impact. These bumpers are used in almost every industry in the world ranging from loading bays to go-kart tracks. They provide cushioning, shock absorption and noise reduction by harnessing the unique dampening properties of polyurethane.

Polyurethane is a durable polymer known for its flexibility and toughness. These bumpers can be seen as a first line of defense against impact for equipment and machinery especially in industrial and automotive industries.

Polyurethane bumpers are commonly made from polyurethane sheeting, but depending on the intended use, custom urethane tubes, rods and rings can also be used.

These bumpers offer several beneficial characteristics to mitigating the effects of impact, including durability, flexibility, impact resistance, and noise reduction. Let’s unpack these benefits below:

Durability

Polyurethane is highly resistant to wear and tear. This makes its application ideal for uses that require long-lasting performance. As an example, these bumpers can be used on loading dock equipment, enduring impacts from forklifts and trucks without degrading.

Flexibility

The innate flexibility of polyurethane allows it to bend or deflect and return to its original size and shape. This is useful in applications like automotive suspension systems, where the bumpers need to absorb shock and vibrations while maintaining their integrity over time.

Impact Resistance

Polyurethane bumpers have the ability to withstand significant force without deforming, to provide consistent protection. Remember the barbarous weight throwers? In manufacturing facilities, polyurethane bumpers on conveyor systems protect machinery and products from damage caused by heavy impacts, ensuring smooth and uninterrupted operations.

Noise Reduction

Through the dampening abilities associated with polyurethane, these bumpers are able to absorb vibrations and reduce noise. The implementation of polyurethane bumpers leads to a quieter operation. This is ideal in environments such as recording studios or office buildings, where minimizing noise and vibrations is crucial for maintaining a peaceful and productive atmosphere.

Wonder what it takes to start implementing custom urethane products in your operation? Just contact PSI Urethanes to get started.

Factors to Consider When Selecting a Polyurethane Bumper

The key benefits listed above make implementing polyurethane bumpers in your operation an easy choice. There are a few factors to take into account when selecting which type of bumper is best for your intended application, which we will discuss below.

Application Requirements:

When selecting a polyurethane bumper, it is crucial to consider the specific requirements of your application. These include:

- Load Capacity: Determine the amount of weight and force the bumper will need to support and withstand. Higher load capacities will necessitate more robust bumpers, like those used in heavy machinery or industrial loading docks where the bumpers must endure repeated impacts from heavy equipment and loads.

- Environmental Conditions: Consider the environment in which the bumper will be implemented. This includes temperature, moisture and UV light exposure. An example would be bumpers used in outdoor applications, such as marine docks which must be resistant to prolonged UV light, water exposure and temperature variations.

- Specific Use Cases: Specific use cases determine which product should be selected. Does the specific use case require high abrasion resistance or perhaps electrical insulation? Determining the specific material properties required will ensure you choose the correct polyurethane bumper.

Material Properties:

As we mentioned previously, each use case requires its own specific material properties. Depending on the intended application some properties to consider include hardness, abrasion resistance and chemical resistance.

- Hardness: Typically measured through a durometer, a device that applies a specific force to a material and measures the depth of the indentation caused by the force. Polyurethane comes in various hardness levels, also measured in durometers as a unit of measure. Softer bumpers have a lower durometer value and mean they are more flexible, whilst a higher durometer value means the sample is harder and offers better impact resistance.

- Abrasion resistance: If the bumper is to be used in applications that involve friction or contact with abrasive surfaces, a higher abrasion resistance polyurethane will be better suited. Examples of these bumpers include those used on conveyor belts in manufacturing plants, where they come into constant contact with rough materials.

- Chemical Resistance: If the bumper will be exposed to chemicals, ensure that it is compatible with the chemical in question. Choosing incompatible bumpers will result in loss of impact resistance and may pose safety risks ranging from equipment damage due to insufficient protection to human injury if the bumper fails.

Size and Shape:

There is something satisfying when something just fits perfectly. In this sense, take proper measurements to ensure that the size and shape of your polyurethane bumper will be correct.

Dimensions: Measure the space in which the bumper will be installed, to ensure a proper fit.

Design: Consider the specific shape required for your bumper. Some applications may warrant cylindrical bumpers, while for others, totally custom shapes may be required.

PSI can custom-make polyurethane products that fit your requirements. If you need a custom polyurethane solution, reach out to our experts.

Common Applications of Polyurethane Bumpers

Polyurethane bumpers’ beneficial characteristics, versatility, and customizability make them suited for most industries. They are used in industrial operations, the automotive industry and consumer goods amongst other things. Below we take a look at some of the industries in which polyurethane bumpers are implemented to better showcase their range.

Industrial Machinery:

Heavy machinery like conveyors, CNC machines and presses generate significant vibrations during operation. Polyurethane bumpers are used to dampen these vibrations, preventing damage to machinery and also reducing noise levels.

In environments where machine components come into regular contact with one another, the bumpers absorb shock and prevent impacts that may cause misalignment and wear.

Automotive Industry:

In the automotive sphere, polyurethane bumpers can be used for engine mountings, absorbing and dampening engine vibrations. This reduces vibrations on the vehicle resulting in a smoother and quieter drive.

Consumer Goods:

In consumer goods, polyurethane is used in various applications ranging from protective padding to non-slip applications.

Furniture commonly has polyurethane bumpers on the legs and corners to prevent wear and tear and protect against damage to floors and walls.

Electronic devices such as laptops or speakers usually have polyurethane non-slip bumpers on the bottom. These bumpers prevent slipping and provide a stable base.

If these uses of polyurethane bumpers sound valuable to you and your business, get in touch with our team today to get started.

Tips for Making the Right Choice

Now that we have looked at what polyurethane bumpers are, factors to consider when selecting the perfect bumper and the various industries in which they are used; you may be wondering how to get started implementing them in your business.

Here are some tips to help you make the right choice.

Consulting with Experts:

What’s that saying about how it takes a village to raise a baby? In the same way, by consulting with a community of experts you get insight you previously didn’t have and gain a deeper understanding ensuring you select the right polyurethane product. Seeking professional advice helps you have better insight into the most well-suited design and type of polyurethane. This will ensure that the product you choose performs optimally and efficiently for a long time.

Testing and Prototyping:

Try, try and try again. Testing bumpers in real-world applications before finalizing your selection ensures that you make the right choice. There is no better alternative than prototyping and testing when it comes to selecting the correct bumper.

Considering Custom Solutions:

In some cases, standard bumpers may not meet all the application needs of the intended application. In this situation, PSI can assist you in developing a custom solution that addresses any specific challenges you may face, ensuring optimal performance.

Look, we can’t do much about the brute in the gym, but when it comes to your polyurethane needs, we’ve got you covered!

If you are looking for a custom solution to your polyurethane needs, contact PSI and let us assist you.