When it comes to choosing the right material for your project, it’s important to understand the differences between thermoset polyurethane and thermoplastic polyurethane. Both are commonly used in various industries, but each type that has distinct properties and characteristics that make them suitable for different applications.

In this article, we’ll dive into the differences between thermoset and thermoplastic polyurethanes, their properties, and their uses, so you can make an informed decision for your next project.

What Are Thermoset Polyurethane and Thermoplastic Polyurethane?

Thermoset Polyurethane

Thermoset polyurethanes, also known as thermosetting urethanes, are a type of polymer that undergoes a chemical reaction when heated, resulting in a permanent cross-linking of molecules. This process is known as curing, and once it occurs, the material cannot be melted or reshaped.

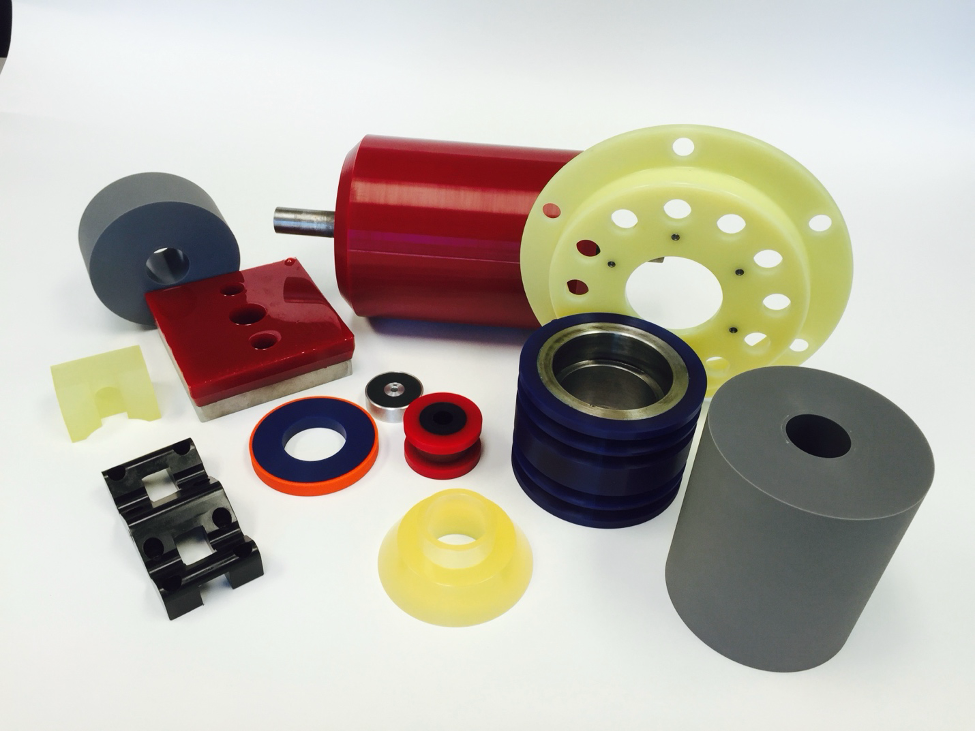

Thermoset polyurethanes are known for their durability, chemical resistance, and high strength. They are commonly used in applications that require high-performance materials, such as automotive parts, industrial equipment, and medical devices. At PSI Urethanes, thermoset polyurethanes are our material of choice for their physical and chemical advantages over thermoplastic polyurethanes in industrial applications.

Thermoplastic Polyurethane

Thermoplastic polyurethanes are a type of polymer that can be melted and reshaped multiple times without losing their properties. This is because they do not undergo a chemical reaction when heated, but rather a physical change.

Thermoplastic polyurethanes are known for their flexibility, elasticity, and resistance to abrasion and impact. They are commonly used in applications that require flexibility and durability, such as sports equipment, footwear, and consumer goods.

Properties of Thermoset vs. Thermoplastic Urethanes

Physical Properties

Thermoset polyurethanes can be custom engineered to the Shore OO, Shore A or Shore D scales, whereas thermoplastic urethanes can only vary within the Shore A scale. Compared to thermoplastic polyurethanes, thermoset urethanes have a higher tensile strength and are more resistant to chemicals and heat. However, they cannot be reshaped with heat once cured.

One advantage of thermoset polyurethane over thermoplastic polyurethane is its ability to be machined. Thermoset urethanes of a hard durometer can be milled, turned, and CNC machined to obtain a desired shape that would be impossible for thermoplastic urethanes.

Thermoplastic urethanes are more flexible and elastic; however, they are also far more limited in their properties. Unlike thermoset polyurethanes, thermoplastic urethanes generally cannot be formulated to a hard durometer. They have a low tensile strength, but compensate with high abrasion and impact resistance. They can also be melted and reshaped multiple times without losing their physical properties to a significant degree.

Chemical Resistance

Both thermoset and thermoplastic polyurethanes have good chemical resistance, but thermoset polyurethanes are generally more resistant to harsh chemicals and solvents. This makes them suitable for applications that require exposure to harsh chemicals and solvents, such as industrial equipment, automotive components, and medical devices.

Temperature Resistance

Thermoset polyurethanes also have a higher temperature resistance than thermoplastic polyurethanes. They can withstand higher temperatures without degrading or melting, making them suitable for high-temperature applications.

Thermoplastic polyurethanes, on the other hand, have a lower temperature resistance and can melt at high temperatures. This is great for recycling material; however, it makes thermoplastic polyurethanes unsuitable for applications that require exposure to high heat.

PSI Urethanes specializes in the development and manufacturing of custom thermoset polyurethane parts. Contact us today to explore the possibilities!

Contact Us

Uses of Thermoset and Thermoplastic Urethanes

Thermoset polyurethanes and thermoplastic polyurethanes each have their own case uses in different industries.

Automotive Industry

Thermoset polyurethanes are commonly used in the automotive industry for various applications, such as bumpers, body panels, and interior components. Their high strength and chemical resistance make them suitable for these applications, as they can withstand harsh weather conditions and exposure to chemicals.

Thermoplastic urethanes are used in automotive parts that require flexibility and impact resistance, such as tires, hoses, and seals. However, thermoset polyurethanes with a soft durometer can also be used in these cases as they can possess the same flexibility with a higher resistance to temperature changes and chemical exposure.

Medical Industry

Thermoset polyurethanes are widely used in the medical industry for applications that require biocompatibility and chemical resistance. They are commonly used in medical devices, such as prosthetics.

Thermoplastic polyurethanes are also used in the medical industry, particularly in applications that require flexibility and durability, such as medical tubing and wound dressings.

Consumer Goods

Thermoplastic polyurethanes are commonly used in consumer goods, such as footwear, sports equipment, and electronics. Their flexibility and impact resistance make them suitable for these applications, as they can withstand repeated use and exposure to everyday conditions.

Thermoset polyurethanes are also used in consumer goods, particularly in applications that require high strength and chemical resistance, such as kitchen appliances and household tools.

Let PSI Urethanes help match you with the right polyurethane for your next project. Contact us today to get started!

Contact Us

Choosing the Right Material for Your Project

When it comes to choosing between thermoset and thermoplastic urethanes, it’s important to consider the specific requirements of your project. Here are some factors to consider:

Strength and Durability

If your project requires high strength and durability, thermoset polyurethanes are the better choice. They have a higher tensile strength than thermoplastic polyurethanes, making them suitable for applications that require resistance to stresses and abrasion. Additionally, thermoset urethane products have a better resistance to chemicals and heat.

Flexibility and Elasticity

For applications where flexibility and elasticity are imperative, thermoplastic polyurethanes may be the material of choice. They can be melted and reshaped multiple times without losing their properties, making them ideal for applications that require repeated use and exposure to impact and abrasion. However, thermoset polyurethanes can also be custom formulated for flexibility and elasticity in cases where other features are required.

Temperature Resistance

Thermoset polyurethanes can perform well in environments with extreme temperatures. They have a better resistance which allows them to function across a wide range of temperatures, and they can withstand high heat without degrading or melting.

Chemical Resistance

Finally, thermoset polyurethanes are a great choice for projects which require exposure to harsh chemicals and solvents. They have a higher chemical resistance and can withstand exposure to chemicals without degrading or melting.

Both thermoset and thermoplastic urethanes have their own unique properties and characteristics that make them suitable for different applications. By understanding the differences between these materials, you can make an informed decision for your next project and ensure its success.

Whether you need high strength and chemical resistance or flexibility and elasticity, there is a urethane material that can meet your specific requirements. PSI Urethanes has the capability to develop custom formulated thermoset polyurethane products for any application you can imagine. Contact us today to get started on your next polyurethane project.