- (800) 888-5156

- (866) 814-0081

- Blog

-

-

Urethane Sheeting

-

Spill Control Products

-

Photo Gallery

-

Request A Quote

-

Contact Us

Finding the perfect material for shock absorption applications is key to enhancing the longevity and performance of machinery and equipment. Although rubber and plastic components have historically remained the most popular choice for shock absorbing products, have you ever considered that there may be an even better material choice for the job?

Urethane, also known as polyurethane, has emerged as a leading material in this field. Often overlooked in favor of cheaper materials, urethane is one of the most underrated material choices for shock absorption and vibration damping applications. In today’s blog we’ll be shedding some light on the features and capabilities of urethane that set it apart as the best material for shock absorption by far.

Before exploring urethane’s capabilities, it’s essential to comprehend the fundamentals of shock absorption.

The Shock absorbers are crucial components in various industries. They are designed to absorb and dissipate energy from impacts, helping to protect machinery and components from damage caused by vibrations and shocks. Proper shock absorption enhances the durability and performance of equipment, leading to increased safety and reduced maintenance costs.

Vibration damping refers to the reduction of oscillatory motion caused by the energy of mechanical systems. Damping materials help to minimize the amplitude of vibrations, ensuring smoother operation and preventing wear and tear on components.

Polyurethane stands out among other elastomers used for shock absorption as a result of its unique properties and customizability. These are just a few features of urethane that make it stand out as the ideal choice for vibration damping.

Urethane is renowned for its impressive physical properties. It combines the elasticity of rubber with the toughness and durability of metal. Urethane’s ability to bear high-stress loads and resist abrasion, tearing, and impacts makes it an excellent material for shock-absorbing applications.

One of urethane’s most notable features is its customizable hardness, or durometer, measured on the Shore scale. This allows for the creation of products ranging from soft gels to rigid plastics, making urethane suitable for a wide array of applications. The flexibility of urethane can be tailored to specific needs, ensuring optimal performance in shock absorption scenarios.

One of urethane’s most notable features is its customizable hardness, or durometer, measured on the Shore scale. This allows for the creation of products ranging from soft gels to rigid plastics, making urethane suitable for a wide array of applications. The flexibility of urethane can be tailored to specific needs, ensuring optimal performance in shock absorption scenarios.

Urethanes with a high durometer are capable of withstanding significant forces, making them ideal for heavy-duty shock absorption tasks. This includes applications where machinery or components are subjected to high-impact stresses. For applications requiring a softer touch, lower durometer urethanes offer greater flexibility and elasticity. This makes them perfect for vibration damping where delicate equipment or precision is paramount.

Urethane’s chemical structure makes it resistant to oils, solvents, and many other harsh chemicals that typically degrade rubber and plastics. It also performs well in extreme temperatures, maintaining its properties in both hot and cold environments. This resilience makes urethane an ideal choice for outdoor and harsh industrial applications.

Urethane’s robust nature translates to a longer lifespan compared to traditional materials like rubber or plastic. Its resistance to abrasion and its ability to rebound after compression contribute to its durability, ensuring that urethane components such as polyurethane bumpers and shock absorbers maintain their effectiveness over time. Although urethane can come at a higher cost than other elastomers, its longevity makes it a more cost-effective choice overall.

When it comes to shock absorption, urethane often competes with materials like rubber, silicone, and various metals. Here’s how urethane measures up against its competitors.

While rubber is a traditional choice for shock-absorbing applications, urethane outperforms it in terms of durability and load-bearing capacity. Urethane’s resistance to wear and environmental factors also gives it an edge over rubber by significantly increasing product longevity.

Silicone offers excellent temperature resistance and flexibility, but it generally lacks the tensile strength and abrasion resistance of urethane. In applications like mounts and bumpers where this strength is critical, urethane is the better choice.

Metals display great strength and durability, but lack the elasticity needed for effective shock absorption. Metal parts can actually have the opposite intended effect and leave valuable components damaged after an impact, which makes it a poor choice for material choice for shock absorption. Urethane, with its elastomeric properties, can absorb and dissipate energy more efficiently than all metals.

Polyurethane motor mounts are a prime example of urethane’s shock-absorbing capabilities. These mounts support and stabilize an engine, reducing vibrations and noise while enhancing the vehicle’s response and handling.

Urethane shock absorbers are essential for protecting sensitive equipment and machinery from impacts and vibrations. Their superior shock-absorbing qualities ensure that machinery operates smoothly and remains free from damage due to sudden jolts.

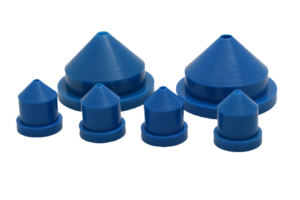

Polyurethane bumpers are strategically placed on machines, walls, and vehicles to absorb and dissipate energy from collisions. Their high impact resistance and ability to return to their original shape after compression make them invaluable in safeguarding assets.

The advancements in urethane technology continue to push the boundaries of its applications in shock absorption.

Our dedication to urethane research and development have led to the creation of our standard formula library and our custom formulation capabilities. If our existing formulas don’t meet the needs of a specific project, we can devise new urethane formulas that offer enhanced properties like increased resilience and improved performance in extreme conditions.

With the ability to create custom-molded urethane parts, we can design components that precisely meet the shock absorption requirements of specific applications.

The combination of urethane with other materials and technologies, such as composite structures or smart damping systems, opens up new possibilities for improving shock absorption performance. AT PSI Urethanes, we’re proud to offer bonded urethane parts like motor mounts, bumpers, and other shock absorbing components. With our capabilities we can bond urethane to metals and some plastics.

Urethane’s outstanding shock absorption qualities stem from its customizable hardness, resistance to environmental factors, and superior physical properties. These characteristics make it the best material for applications that require reliable vibration damping and energy absorption.

For businesses and engineers seeking materials that can extend the life of their equipment and improve operational efficiency, urethane is the best material for shock absorption. Its unparalleled ability to dissipate shocks and vibrations ensures that machinery, vehicles, and structures remain protected and perform at their best.