Additive manufacturing methods such as 3D printing are impacting the way manufacturers do business and are part of the digitalization of manufacturing that is often referred to as Industry 4.0. 3D prototype printing has been around for decades and is often referred to as rapid prototyping. In recent years, its popularity has grown and utilization has spread across a myriad of industries.

3D printing adds tremendous value to the manufacturing industry and is a cost-effective tool for OEMs. The true potential for 3D printing for manufacturing lies in the new opportunities for innovation and creativity that it provides – and not what forms of manufacturing it will replace. At PSI, 3D prototype printing is often used in conjunction with other manufacturing techniques to achieve an overall manufacturing strategy that is the most cost-effective for customers.

What is 3D Printing?

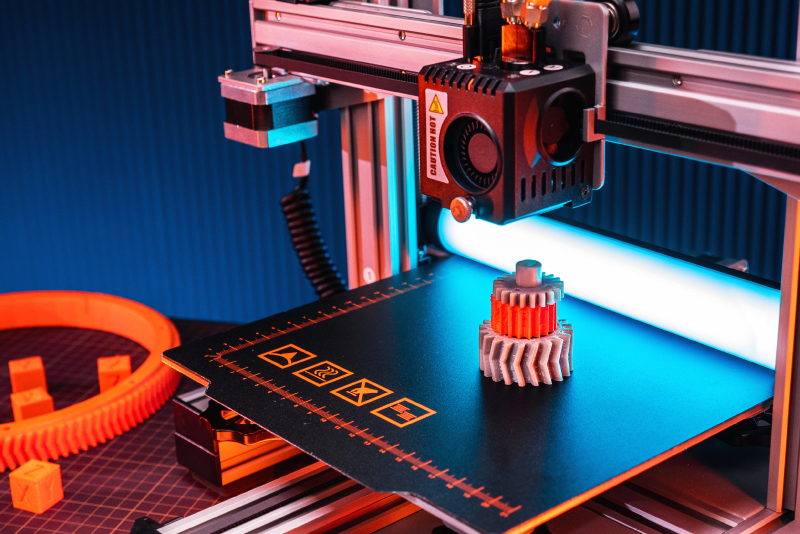

3D printing is one of several technologies under the umbrella of Additive Manufacturing (AM), named as such since it starts from nothing and builds layer by layer of material. Many conventional manufacturing methods are subtractive since they start from a block of something and material is removed.

3D printing for manufacturing is a process that builds a three-dimensional object based on a Computer Aided Design (CAD) sketch. The 3D printing machine uses the CAD data to add successive layers of liquid, powder, or other material to manufacture a 3D object. The technology for creating these layers varies by printer and includes fusing melted filaments, sintering with lasers, or curing with UV light or binding agents.

3D prototype printing technologies are often faster than traditional machinery and, thus, have been used for many years to rapidly manufacture prototypes, known as rapid prototyping. This method allows designers to quickly manufacture one or more inexpensive prototypes in order to determine which one should be selected for production as part of the iterative process to fine-tune the final design. 3D prototype printing saves manufacturers significant time and money in prototyping and the design phase. This technology continues to primarily be used for 3D rapid prototyping but in some cases has advanced beyond prototyping into small, and even some large volumes, of production.

What Are the Advantages of 3D Printing?

3D printing for manufacturing offers many benefits over traditional manufacturing, and more and more manufacturers are turning to 3D printing to reap the benefits. All of the advantages below lead to cost savings and a more cost-effective manufacturing solution for OEMs.

- Faster Cycle Times: this is the most well-known benefit of 3D printing for manufacturing, especially when it comes to cast urethane molding. With the help of 3D printing, the time and cost of the master pattern creation process can be reduced significantly compared to traditional metal machining methods. In fact, the turnaround time can be reduced from several weeks to a few days. In addition, 3D prototype printing only needs a new CAD input in order to manufacture a new product and does not require retooling or machine changes – resulting in significant time savings.

- Single Part with Less Assembly: 3D printed parts are one, single piece and do not require significant secondary operations such as assembly or welding, further reducing lead times. This is a big advantage as multiple parts can be combined into a single part with 3D printing, in some cases eliminating assembly steps.

- More Optimal Part Designs: the quicker turnaround times that 3D prototype printing delivers enables designers to tweak and optimize the design repeatedly without spending more time on design iterations. This process often delivers a more optimized part design in the end as designers have the opportunity to rapidly create more prototypes without sacrificing the budget or delaying the project timeline.

- More Design Flexibility: 3D prototype printing is able to achieve complex part designs that are challenging, in some cases infeasible, with machining. 3D printing for manufacturing provides designers with more creativity and flexibility in their part designs in order to experiment with different part shapes and lighter components to address market demands.

- Less Waste Generation: since additive manufacturing methods such as 3D printing for manufacturing start with nothing and create layer upon layer until the final product is achieved, these techniques generate significantly less waste than traditional, subtractive manufacturing, and in some cases, waste can be entirely eliminated. This is a big benefit as companies are becoming more focused on sustainability and their environmental footprint.

- Just-in-Time Production: 3D printing for manufacturing allows manufacturers to fabricate parts on-demand and as needed rather than stock piling spares in a warehouse. This approach results in optimized inventory with lower storage and inventory costs.

- More Nimble Production: in most cases, traditional manufacturing requires tooling that is difficult to modify once production is initiated. However, 3D printing for manufacturing is able to innovate and tweak designs and fabricate new molds based on customer feedback during the production phase with minimal impacts on the project timeline or budget.

Would your team benefit from the speed and flexibility of 3D prototype printing?

Contact PSI to learn more about our 3D prototype printing for cast urethane molding.

PSI’s 3D Printing for Cast Urethane Molds

For over 50 years, PSI has created urethanes that are stronger, tougher and more durable than products made from conventional elastomers, plastics, and metals. During this time, PSI has been setting the industry standard in custom urethane products, staying on the cutting edge of advances in new materials, designs, and processing technologies. At PSI, we know that utilizing state-of-the-art equipment and technologies leads to better quality and flexibility for our customers.

PSI is always looking for opportunities to leverage the latest advancements. For example, our team now offers 3D prototype printing for cast urethane molding. Our 3D printed molds deliver faster turnaround times and are more cost-effective than traditional metal molding methods that require machining. Our 3D printed molds provide significant cost and schedule benefits to our customers. Our 3D prototype printing can create single and multi-cavity molds with finishing options available for parts that require a smooth finish. Contact our team today to learn more about our 3D prototype printing solutions for custom cast urethanes.

About PSI Urethanes

Since 1966, through our own independent research and activity in the Polyurethane Manufacturers Association, PSI Urethanes has stayed on the leading edge of urethane technology – including developing advances in new materials, comprehensive designs, and processing technologies. Today we are among the most respected and trusted suppliers of custom urethane products.

We operate from our 45,000-square-foot manufacturing facility in Austin, Texas, which houses an extensive stock of polyurethane products. Our fully equipped manufacturing facility includes a versatile range of processing machinery, which allows us to work on unique, one-of-a-kind projects, as well as high volume components. Our in-house engineering, tooling, and custom mold shop, produces custom and stock production orders with exceptionally fast turn-around times. From conception to prototyping, to final production runs, our technical representatives and design engineers will work closely with your staff to meet your critical tolerances and specifications. You are guaranteed to receive experienced, professional, and personalized service from the first contact through your on-time delivery, with complete confidentiality and dedication to protecting your good name.

PSI Urethanes specializes in custom urethane products. Contact us today to see how we can help with your next manufacturing project, or give us a call at 1-800-888-5156.