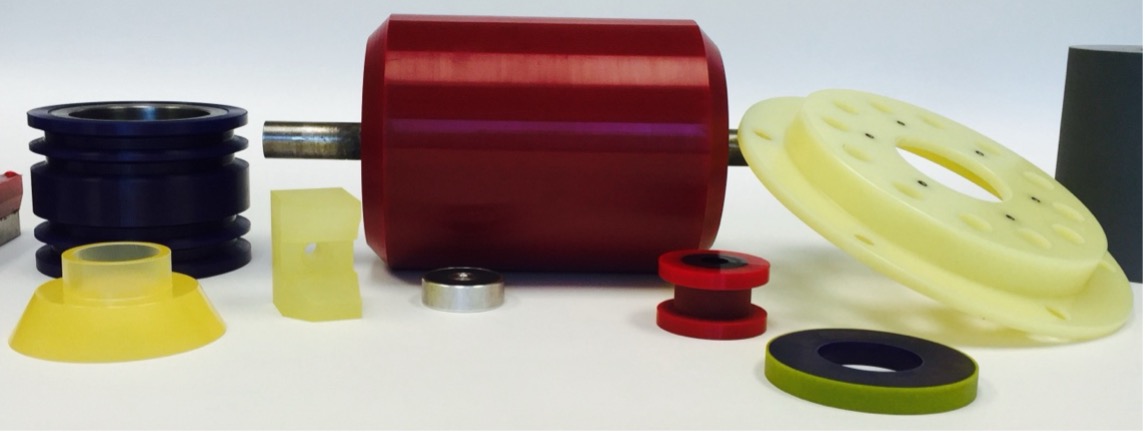

Polyurethane (PU) is one of the most versatile materials for making parts and products. It is available in a variety of sizes, durometers, formulations, tolerances and colors for use in a wide range of applications. In addition to the unmatched versatility it offers, polyurethane is also one of the strongest, toughest, and most durable materials. In fact, urethane parts are commonly viewed as a better value, because parts made with other materials often crack, break, tear, swell, deteriorate and abrade.

Key Advantages of Custom Polyurethane Parts

In cases where metals are too rigid and plastics are too brittle, many manufacturers turn to elastomers for their flexibility. When looking to manufacture custom parts, rubber tends to be a popular choice. However, urethane material can offer all of the same benefits as rubber, and then some. Polyurethane has many advantages over rubber, plastic, and other elastomeric materials including these 5:

1. Non-Marring Properties

Polyurethane eliminates the risk leaving of visible smudges or marks on surrounding components due to its non-marking material makeup.

2. High Customizability

It is also available in a variety of custom colors for easy recognition and part segmentation. This makes it an excellent choice for visual wear indicators.

3. Increased Durability

Urethane allows operators to replace parts far less often because of its tougher physical properties which extends part lifespan.

4. Shape Memory

Urethane absorbs shock and distributes weight in a process called deflection. Where other elastomers compress and deform, polyurethane deflects instead and returns to its original shape once force is removed.

5. Manufacturability

Urethane parts can be custom cast to meet the exact specifications of any project with consistent quality between runs. Unlike other elastomers, polyurethane can also be easily machined and turned with the right formula for further control over tolerances.

6. Chemical Resistance

Urethane is highly resistant to chemicals and weathering, making it an ideal choice for industrial coatings and products that need to withstand harsh environments.

The Value of Urethane Parts

There are several reasons why businesses choose urethane over other materials for their products and applications. In addition to the physical benefits that it offers, urethane is also a highly cost-effective material.

When compared to other materials such as metal, rubber, and composites, PU generally has a lower up-front investment cost. Combined with the extended life that comes with its resistance to wear, urethane often provides manufacturers with the best financial value. This makes it an attractive option for businesses looking to reduce costs without compromising on quality.

Looking to reduce your manufacturing costs? Contact us today to get a complimentary quote.

Contact Us

How to Choose the Right Urethane Supplier

Choosing the right urethane supplier is crucial to the success of your project. Here are some factors to consider when selecting a urethane supplier:

Experience

Look for a supplier that has experience working with urethane and creating custom parts and products. This experience will ensure that they understand the material and can provide you with high-quality products.

Quality control

A reputable urethane supplier should have a robust quality control process in place to ensure that their products meet the required standards. Ask about their quality control procedures and certifications to ensure that you are getting the best products.

Customization capabilities

If you need custom urethane parts or products, make sure that the supplier has the capabilities to create them. Ask about their customization process and the types of formulations they can provide.

Customer service

A good urethane supplier should have excellent customer service. They should be responsive to your inquiries and provide you with the necessary support throughout the process.

Extensive Applications of Polyurethane Parts and Products

Due to its extreme versatility and durability, urethane can be used across a variety of applications to provide the reliability and strength needed to outlast the competition. PSI Urethanes sells a variety of polyurethane parts and products including rollers, rods, rings, tubes, and sheeting. Here are a few of the most common custom urethane products we make along with some of their most common applications:

Polyurethane Rollers:

- Wear and cut resistant

- Can carry up to four times higher load rubber

- Stands up to harsh environments

Polyurethane Rods:

- Made of tough, crack-resistant and abrasion-resistant material

- Lasts significantly longer than conventional rubbers and plastics

- Available in custom diameters, lengths, hardness and colors

Polyurethane Rings:

- Developed from tough, premium grade urethane

- Available in custom sizes, formulas, colors and durometers

- Tight tolerances and ground finishes

Polyurethane Tubes:

- Created with premium grade urethane

- Can be customized to meet unique specs like diameter, length, hardness and color

- Provide a protective barrier for critical mechanical components

Polyurethane Sheeting:

- Available in a wide range of colors, durometers, and custom sizes

- Can be created with extremely tight tolerances

- Polyurethane sheeting can be developed to meet your project’s specific requirements.

Polyurethane Safety Seals:

- Made from durable polyurethane

- Provide tight seals

- Designed to stop or prevent spills, including hazardous materials.

Additional applications for our custom polyurethane parts and products include:

| • Absorbers | • Dies | • Pads |

| • Bearings | • Elastomers | • Pinch Rollers |

| • Blocks | • Flexible Couplings | • Plugs |

| • Bumpers | • Gaskets | • Scrapers |

| • Bushings | • Gears | • Sheets |

| • Cams | • Impellers | • Shocks |

| • Capper Rings | • Isolators | • Springs |

| • Casters | • Linings | • Straps |

| • Coverings | • Metal Forming Pads | • Washers |

| • Cutting Surfaces | • Wheels |

Extend the life of your parts by switching to polyurethane. Get in touch with PSI today to find out how.

Get Started

As you can see, PU parts and products can be used across a variety of applications and are commonly recognized as a better value than parts made with other materials. Its durability, versatility, and resistance to chemicals and weathering make it an ideal choice for creating custom parts. When choosing a urethane supplier, make sure to consider their experience, quality control procedures, customization capabilities, and customer service. With the right supplier, you can take advantage of the many benefits of urethane and create high-quality products that meet your specific needs.

PSI Urethanes sells custom molded urethanes, ranging from low quantity prototypes to full production products. With our custom urethane parts, you can be confident in your operations knowing you have selected the highest quality material for the job and that you may never have to replace your parts again. To learn more about custom urethane parts and products check out our custom urethane gallery.