Polyurethane occupies a unique position in engineering material selection by combining characteristics associated with rigid plastics and flexible elastomers. Its use spans impact-absorbing components and high-load industrial parts. How polyurethane is classified directly affects thermal behavior and load response, influencing service life and lifecycle cost.

This raises a critical materials question: Is polyurethane a thermoset or a thermoplastic? The answer determines how the material responds to heat, stress, and repeated mechanical loading. Understanding the thermoset vs thermoplastic distinction enables engineers to specify formulations based on application-driven requirements rather than generalized material categories.

With more than 50 years of experience, PSI Urethanes is recognized as an industry authority in custom cast polyurethane solutions, helping technical teams translate polymer chemistry into repeatable, application-specific results.

Understanding Polymer Basics: Elastomers, Plastics, and Polyurethane

Elastomers are long-chain polymers that stretch under load and return to their original shape due to molecular chains that uncoil and recoil without breaking chemical bonds. This behavior allows them to absorb energy while remaining flexible across a wide temperature range. Compared to conventional rubbers, engineered elastomers like polyurethane provide higher strength and better abrasion resistance in demanding environments.

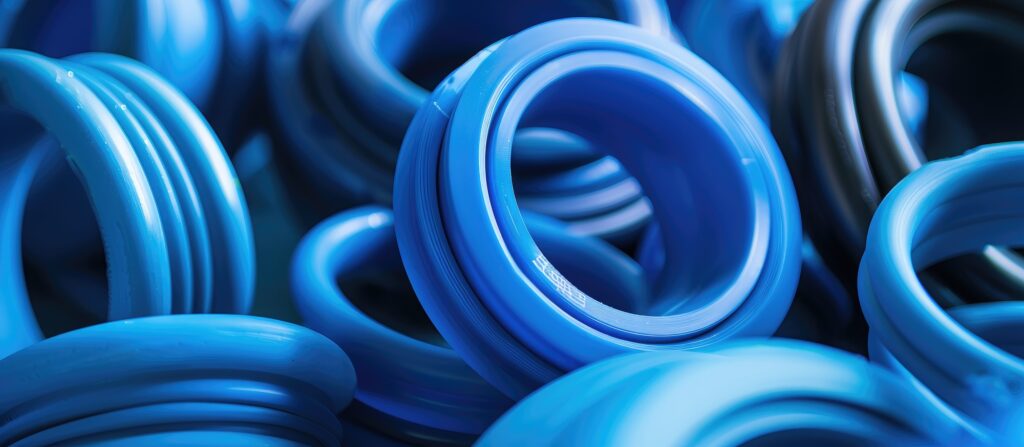

Polyurethane is a family of polymers with tunable properties controlled by formulation. Chemistry adjustments allow flexibility or rigidity, load-bearing capability, and resistance to chemicals or abrasion. This versatility explains why polyurethane plastics are used in applications ranging from soft seals to rigid structural components, making the thermoset vs thermoplastic distinction critical in material selection.

Ready to specify the right polyurethane for your application? Discover how PSI Urethanes’ custom cast solutions can support demanding design requirements.

Thermoset vs Thermoplastic: Key Differences Explained

Thermoset polymers are created through a chemical curing process that forms a permanently crosslinked molecular structure. Once cured, they cannot be melted or reshaped, and heat will degrade the material rather than soften it. This structure provides strong resistance to creep under load and stability in elevated-temperature environments.

Thermoplastics are made of linear or lightly branched polymer chains that soften or melt when heated, allowing repeated reshaping. While this simplifies processing, it can reduce strength under sustained load. In the thermoset vs thermoplastic comparison, thermosets are favored for high-stress, high-temperature applications, while thermoplastics offer easier fabrication.

Is Polyurethane a Thermoset or Thermoplastic?

Polyurethane can be either a thermoset or a thermoplastic, depending entirely on its formulation and processing method. The chemistry used during production determines whether the polymer chains become permanently crosslinked or remain melt-processable.

This dual nature makes polyurethane uniquely valuable. Designers can specify a formulation aligned with their application’s mechanical, thermal, and environmental requirements. The ability to choose between thermoset and thermoplastic behavior gives polyurethane a versatility few materials can match, reinforcing the importance of understanding thermoset vs thermoplastic distinctions early in the design process.

Thermoset Polyurethane: Properties, Performance, and Applications

Thermoset polyurethane is engineered for demanding environments where conventional plastics or rubbers fall short, particularly when evaluating thermoset vs thermoplastic material options.

Key material characteristics include:

- Strong resistance to abrasion, tearing, and cutting

- High load support with minimal permanent deformation

- Dimensional stability under repeated stress

- Broad durometer range from Shore OO through Shore D

Unlike thermoplastics, thermoset polyurethane does not have a true melting point. It maintains its shape until thermal degradation occurs, with continuous-use temperatures up to approximately 250°F depending on formulation. This behavior is often misunderstood as a polyurethane melting temp, but heat capability is defined by service limits rather than melt behavior.

Common applications include:

- Rollers, wheels, and drive components

- Die-cutting and metal forming pads

- Food processing components using approved formulations

- Military, aerospace, and heavy industrial parts

PSI Urethanes’ custom cast urethane solutions allow these components to be engineered to precise specifications.

Below is a summary of the physical properties and abilities of thermoset polyurethane and thermoplastic polyurethane. Visit our website to learn more about the properties of PSI Urethanes’ thermoset and thermoplastic polyurethanes.

Thermoset Polyurethane | Thermoplastic Polyurethane | |

Abrasion Resistance | Excellent for abrasive applications because of its high resistance to abrasion and cutting. | Will tear with abrasive applications. |

Heat Resistance | Able to withstand temperatures of up to 250° without problems. | Have a lower melting point and will soften, deform, and degrade in temperatures above 250°. |

Hardness | Has a wide range of durometers available in A & D scales. | Has a very small range in “A” scale only. |

Load Bearing Capacity | Able to hold a large amount of weight per square inch. | Unable to hold a large amount of weight without destroying the material. |

Have a challenging component or unique material requirement? PSI Urethanes partners with engineers to develop custom thermoset polyurethane parts built for real-world demands.

Thermoset vs Thermoplastic Polyurethane: Side-by-Side Comparison

When comparing thermoset and thermoplastic polyurethane, several factors stand out. Thermoset polyurethane offers superior abrasion resistance, higher heat tolerance, and greater load-bearing capability. It also supports a wider hardness range and longer service intervals, contributing to lower lifecycle cost.

Thermoplastic polyurethane provides ease of processing and reshaping but may fall short in high-stress applications. For custom molded parts, thermoset formulations often provide more consistent results, reinforcing why thermoset vs thermoplastic analysis is critical during material selection.

Why PSI Urethanes Specializes in Thermoset Polyurethane Solutions

PSI Urethanes focuses on thermoset polyurethane because it delivers strength, toughness, and versatility beyond many conventional materials. Custom cast urethane outperforms commodity plastics and standard elastomers in demanding environments where load, abrasion, and heat are constant challenges.

The company offers in-house engineering, mold making, and rapid prototyping, allowing tight control over material formulation and part geometry. PSI Urethanes produces a wide range of part sizes and shapes, including precision sheet stock with standard tolerances of ±0.005 inches. This capability supports complex designs where consistency matters, particularly when weighing thermoset vs thermoplastic choices.

Polyurethane’s Versatility Starts with the Right Partner

Polyurethane’s strength as an engineering material comes from its ability to be formulated for applications ranging from flexible components to rigid, load-bearing parts. The thermoset vs thermoplastic distinction shows how material classification affects heat response, load handling, and abrasion resistance.

Thermoset polyurethane excels in demanding industrial environments where heat, friction, and mechanical stress challenge conventional plastics and rubbers. Custom components such as rollers and die-cutting pads demonstrate the importance of proper formulation.

PSI Urethanes provides the material expertise and custom cast urethane manufacturing needed to deliver reliable, application-driven solutions.

Looking for expert guidance on polyurethane material selection? Connect with PSI Urethanes to discuss your next project.

FAQs

Is polyurethane a thermoset or a thermoplastic?

Polyurethane can be formulated as either a thermoset or a thermoplastic. Thermoset polyurethane offers high durability and heat resistance, while thermoplastic polyurethane (TPU) provides flexibility and the ability to be melted and reprocessed.

What is the main difference between thermoset and thermoplastic polyurethane?

Thermoset polyurethane cannot be melted after curing, giving it excellent abrasion, load-bearing, and temperature resistance. Thermoplastic polyurethane can be reheated and reshaped, making it more flexible but less durable under high heat and heavy load.

Which type of polyurethane is best for high-stress industrial applications?

Thermoset polyurethane is typically the preferred choice due to its superior abrasion resistance, wide hardness range, and ability to withstand heavy loads and temperatures up to 250°F.

Why choose polyurethane over rubber or plastic?

Polyurethane offers a unique blend of elasticity, durability, abrasion resistance, and customization options that outperform many rubbers and plastics in demanding OEM applications.