- Jump To:

- Types

- Advantages

- Resources

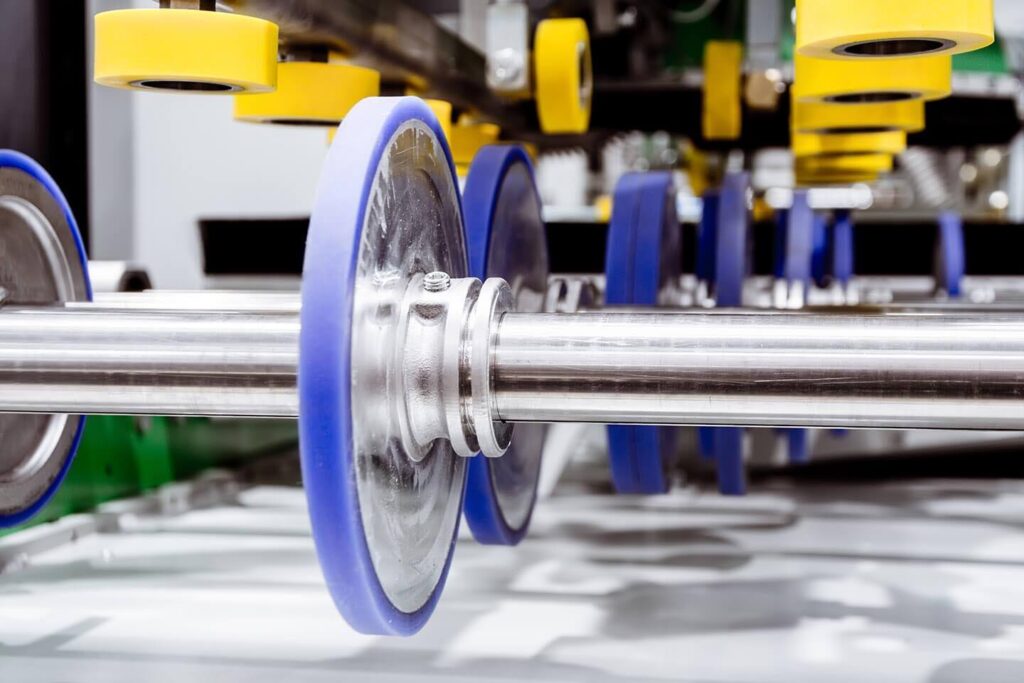

Cast Polyurethane Impellers

Maintain Maximum Pump Efficiency With The Right Impeller

Impellers are an essential component in the operation of many forms of machinery—both big and small. They can be found in various types of pumps, centrifugal compressors, wind turbines, jet skis, agitated tanks, and even consumer washing machines.

PSI Urethanes can meet your custom polyurethane impeller needs regardless of the application.

Polyurethane is the preferred material for many impeller applications, especially highly abrasive and wear intensive applications.

What Is An Impeller?

How Does An Impeller Work?

When the impeller is made to rotate, it makes the fluid surrounding it rotate also. This imparts a centrifugal force to the fluid and moves it out radially. In a pump, the fluid will enter the impeller through the eye(the middle), be pushed by the vanes and exit the pump through a tube, hose, or pipe.

During the process, rotational energy is transferred to the fluid. At the discharge side of the impeller, the kinetic energy and pressure of the fluid rise. On the suction side, fluid is displaced and there’s negative pressure at the eye of the impeller. This pressure helps suck fluid into the system, keeping the whole process going.

Types of Impellers

Open Impellers

An open impeller has blades that are attached to a hub. This design looks very similar to a boat propeller or a fan. They are ideal for situations in which the impeller needs to be cleaned on a regular basis or there is a risk of blockage. Though an open impeller tends to have low efficiency, its efficiency can be regularly maintained through impeller clearance adjustment.

Closed Impellers

A closed impeller, also called a shrouded impeller, has one circular plate on each side. It ideal for pumping water and other liquids at higher head pressures. While the closed design is initially very efficient, it loses its efficiency as the wear ring clearance increases. The design of this impeller makes it more difficult to modify and because its internal parts are hidden, it’s hard to inspect for flaws.

Semi-Open Impellers

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.

Advantages of Polyurethane Impellers

Polyurethane slurry pump impellers outperform plastic, rubber, and a number of metals in many ways, including:

- Increased hardness range

- Twice the tensile strength and tear strength as rubber

- High energy absorption capability

- Resistant to oil, chemicals, and environmental conditions

- Extremely high abrasion resistance

Advantages of Polyurethane Impellers

Polyurethane slurry pump impellers outperform plastic, rubber, and a number of metals in many ways, including:

- Increased hardness range

- Twice the tensile strength and tear strength as rubber

- High energy absorption capability

- Resistant to oil, chemicals, and environmental conditions

- Extremely high abrasion resistance

Custom Polyurethane Impellers From PSI Urethanes

Industries Utilizing Urethane Impellers

Many industries rely on urethane impellers for their needs, including: