- Jump To:

- Specs

- Benefits

- Applications

- Gallery

- Resources

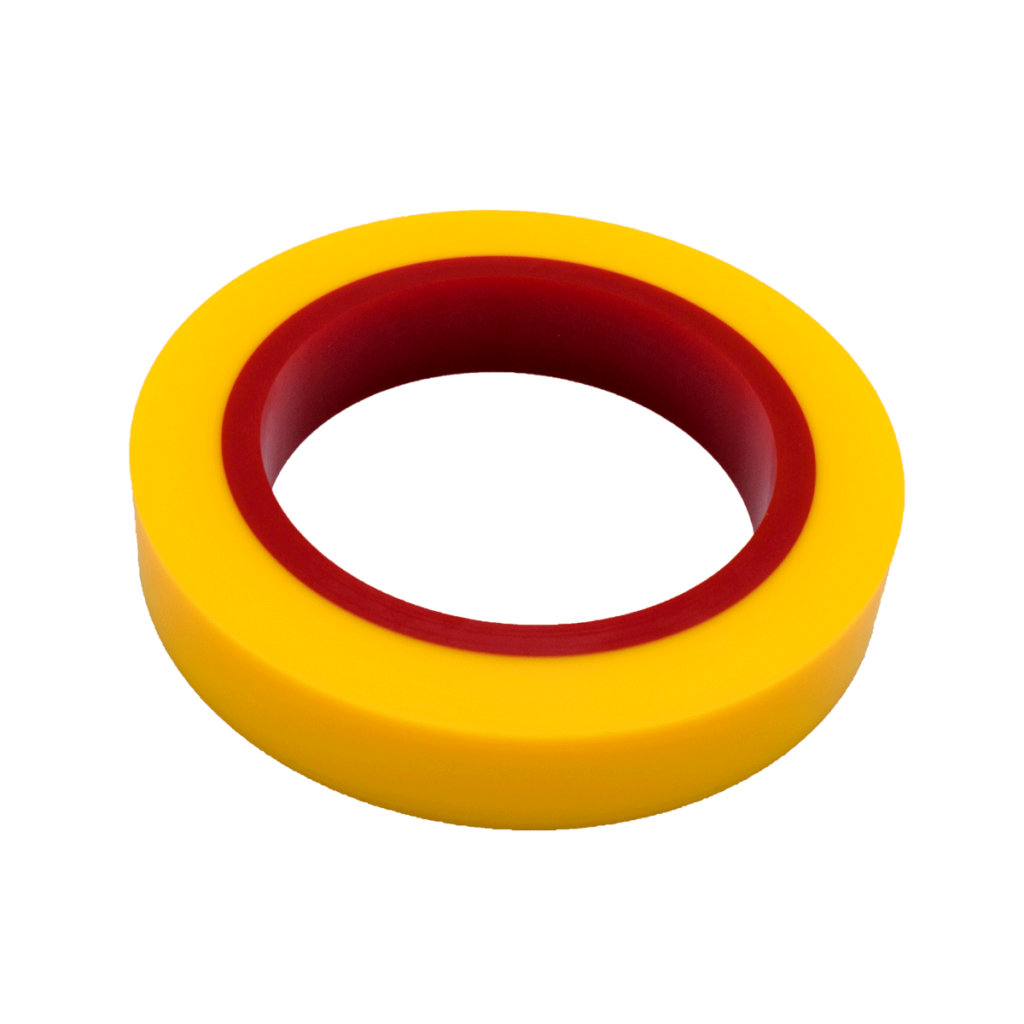

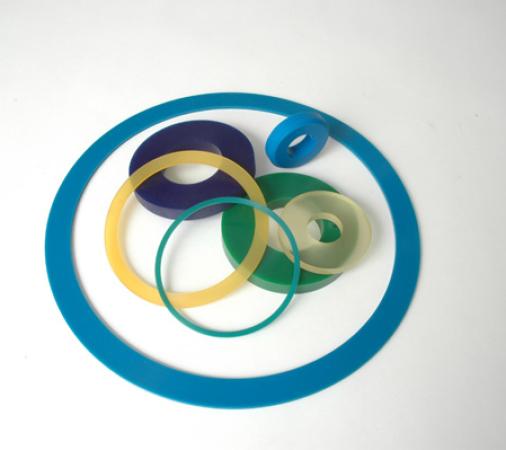

Cast Polyurethane Rings

Tougher in a Wide Range of Applications

PSI produces cast polyurethane rings made from tough, premium grade urethane, which ensures they will hold up in a wide range of applications. With our urethane ring seals, you will reduce equipment downtime and save on material costs. PSI offers custom sizes, formulas, colors, and durometers (hardness). We also offer tight tolerances, ground finishes, and dual durometer rings.

PSI will help you develop prototypes and will deliver full production quantities when needed. Our custom rings have little or no tooling costs. PSI will custom formulate to meet your specific needs, including FDA wet or dry requirements.

Cast Polyurethane Ring Specs

Durometer Hardness

- 25 Shore OO

- 40 Shore OO

- 50 Shore OO

- 70 Shore OO

- 20 Shore A to 90 Shore A

- 50 Shore D to 75 Shore D

Durometer Reference Calculator

For reference, this hardness is as soft as a Gel Shoe Insole

For reference, this hardness is as soft as a Rubber Band

For reference, this hardness is as soft as a Pencil Eraser

For reference, this hardness is as soft as a Tire Tread

For reference, this hardness is as soft as a Shopping Cart Wheel

For reference, this hardness is as soft as a Hard Hat

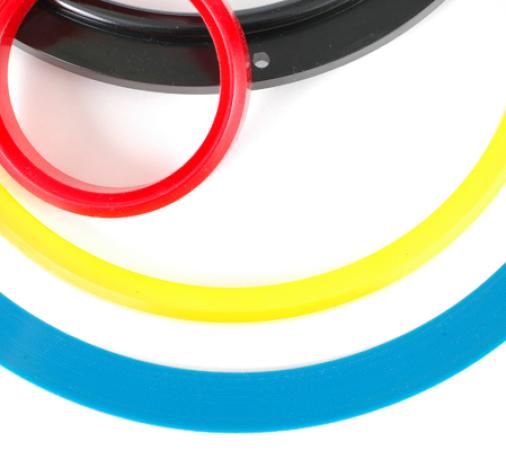

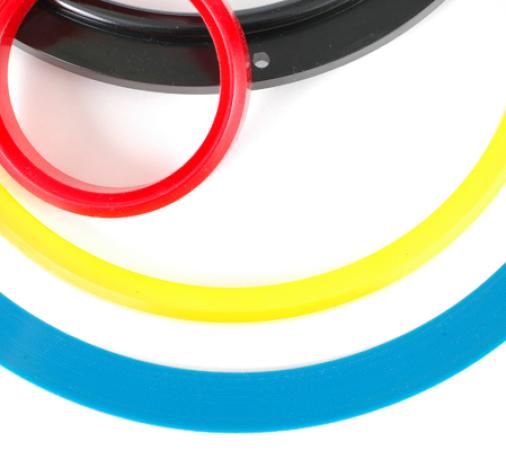

Standard Colors

Natural or peach colors available

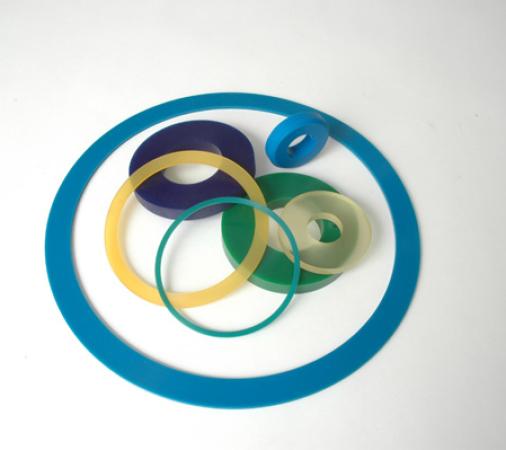

Sizes

- 2.0″ I.D. / 4.0″ O.D.

- Thickness or Face: 1/2″

Application Specific Formulations

- FDA FDA Dry Food Approved 30A to 65D and FDA Wet Food Approved 30A to 90A

- Static Dissipative material is available in 25 OO to 70D

- Graphite Filled

- Dual Durometers

Benefits of Polyurethane Rings

Cast polyurethane rings maintain their elasticity and strength over the complete range of hardness. They can be stretched and still return to their original dimensions, even at high durometers.

On the other side of elasticity is compression. Urethane is better than rubber when it comes to compression set and has a broader range of durometers (hardness) to fit many applications. At PSI, we have custom formulations in a variety of durometers ranging from “dead” for shock absorbing and “rebound” for repeated flexing. Urethane rings also maintain excellent resistance to chemicals, mineral-based oils, hydrocarbons, fats, greases, petroleum products, and specific solvents.

The technicians at PSI can even formulate urethane to remain flexible in Arctic-like conditions and temperatures as high as 250 degrees Fahrenheit, or to sustain sudden drops in temperature. (Though we don’t recommend continuous use in water hotter than 180 degrees Fahrenheit.)

Common Urethane Ring Applications

- Capper Rings

- Packing Rings

- Tubular Springs

- Inserts

- Seals

- Vibration Isolators

- Spacers

- Retainers

- Bushings

Call PSI for a Custom Quote

Ask Our Experts.

Contact us today to learn how we can meet your project’s requirements.

Custom Urethane Rings Gallery

Custom polyurethane rings are durable and have the ability to withstand a wide range of applications, reducing equipment downtime and saving on material costs. Learn more about custom urethane rings.

Custom Urethane Rings Gallery

Custom polyurethane rings are durable and have the ability to withstand a wide range of applications, reducing equipment downtime and saving on material costs. Learn more about custom urethane rings.

Industries Utilizing Cast Urethane Rings

Many industries rely on urethane rings for their needs, including:

Food Processing

Metal Forming

Military

Die Cutting

Fluid Cell Remold

OEM's

Marine

Process Automation

Automotive

Recommended Reads

As versatile as urethane rings are, there’s an important reason companies choose urethane over rubber, another popular material for industrial applications…

We frequently hear the question, “How can I get the best longevity from our capper rings?” To answer this, it all comes down to your application and the formula…

PSI offers custom sizes, formulas, colors, and durometers (hardness), as well as tight tolerances, ground finishes, and dual durometer rings…