Material selection is a key consideration when designing a part or upgrading an existing design – and there is no shortage of material options to choose from. Many industries prefer polyurethane as it offers many advantages over conventional materials like metal, plastic, and rubber. The following compares polyurethane to each of these conventional materials in detail in order to explain why polyurethane is superior to metal, plastic, and rubber.

Why Polyurethane is Superior to Metal

Many industries prefer the versatility and durability of urethane over metal. Below are some key advantages of using polyurethane over metal.

· Outstanding Sound Dampening: polyurethane products offer great shock absorption and noise reduction, resulting in a much quieter operating environment – especially when compared to metal parts.

· Lighter Weight: it is not surprising that polyurethane parts weigh less than metal. This offers a huge advantage in many sectors like the automotive industry where manufacturers are constantly looking for opportunities to reduce vehicle weight.

· Elastomeric: polyurethane can be compressed up to 25% of its normal size and still rebound back to its original size. Conversely, metal is not an elastomer and has no ability to flex.

· Non-Marring: polyurethane does not mar material it comes in contact with whereas the metal often marks or damages materials it contacts.

· Abrasion, Chemical, and Corrosion Resistance: polyurethane can be customized to handle a variety of applications, including abrasive, water and chemical environments.

· Cost effective: polyurethane parts are typically less expensive to mold than metal, especially for low volume runs.

Could your project benefit from custom urethane bonding?

Contact the professionals at PSI to learn more about range of solutions including urethane bonding.

Why Polyurethane is Superior to Plastic

Many industries rely on polyurethane and prefer urethanes over plastics. Here are a few reasons why:

· Strength & Impact Resistance: plastics often crack or break under impact loading or stress, especially at higher durometers (hardness). Conversely, urethane is not brittle and will maintain its strength and impact resistance over a range of durometers. At PSI, we have a full range of durometers on the “A” scale to 70 on the “D” scale, whereas plastics like UHMW are much more limited in their durometers.

· Sound Dampening: polyurethane products offer more shock absorbing and sound dampening compared to plastics.

· Elasticity: plastics tend to stretch and either break or deform, unable to return to their original shape. Urethane has incredible elasticity and is able to be stretched and regain its shape without sacrificing strength or integrity.

· Durability and Temperature Range: urethane parts are more durable and have a higher abrasion resistance than plastics. Urethanes are also more tear-resistant than many plastics and can withstand a wide range of operating conditions and environments without sacrificing performance. For example, urethane maintains its excellent mechanical properties in extreme high and low temperatures – something plastic simply cannot do.

· Self-Healing: plastic is not self-healing whereas polyurethane is. This characteristic can be a crucial differentiator and important for products such as cutting surfaces for work benches or tabletops.

· Chemical and Ozone Resistance: polyurethanes are resistant to degradation from a wider spectrum of chemicals than plastics. At PSI, our thermoset urethane holds up to exposure to chemicals, ozone, and oxygen, whereas Nylon and UHMW do not.

· Versatility: when compared to plastic, urethane offers versatility and reliability that is unmatched. Polyurethane can be formulated to meet the specific needs of each and every application, and custom urethane formulations can be made to meet the desired color, thickness, shape, and durometer (hardness).

· Cost-Effective: polyurethane products are a very cost-effective solution and are often less expensive than plastic.

Why Polyurethane is Superior to Rubber

Many industries prefer polyurethane over rubber. Below are several examples of why polyurethane is superior to rubber.

· Non-Marring: polyurethane does not mar material it touches whereas rubbers that contain carbon can leave black marks on products during contact.

· Strong Chemical and Water Resistance: when it comes to resistance to chemicals, oxygen, and ozone, urethane is superior to rubber. Urethane has excellent resistance to mineral-based oils, hydrocarbons, fats, greases, petroleum products, and specific solvents. Additionally, polyurethane outperforms rubber in applications that are either submerged or exposed to wet environments for an extended period of time, where rubber may rot.

· Superb Abrasion Resistance: polyurethane has great abrasion and wear resistance, resulting in longer product life cycles. In fact, when severe abrasion is a factor, urethane has been known to outwear other materials by a factor of five-to-one to ten-to-one. In cases where urethane products experience a great deal of abrasion from combining dynamic loads and high friction, polyurethane surpasses natural rubber.

· Incredible Tensile Strength & Elongation: polyurethane has a higher load-bearing capacity and is able to handle more pounds per square inch than rubber without rupturing and breaking apart.

· Withstand Extreme Temperatures: while rubber tends to harden, polyurethane remains flexible at low temperatures. The professionals at PSI can formulate urethane to remain flexible in Arctic-like conditions or temperatures as high as 250° Fahrenheit – all without sacrificing performance.

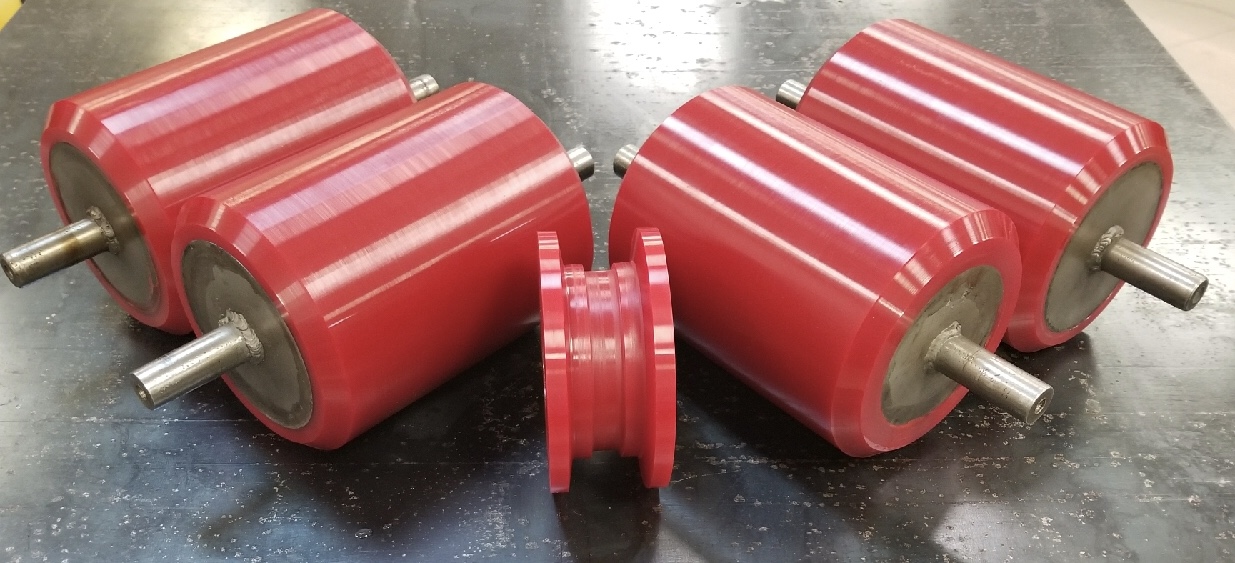

· Excellent Grip: one of the functions of urethane parts, such as conveyor rollers, is to provide a proper level of grip and traction as products are processed. Some materials, such as rubber, have difficulty gripping whereas polyurethane has great grip capabilities and can transport products without disruption.

· Broad range of Formulations, Durometers, and Colors – urethane is versatile and can be customized to your specific requirements. Unlike rubber, the team at PSI can create custom urethane formulations across a range of durometers. PSI also carries a wide variety of resins, curatives, and additives.

· Superior Longevity: most of the properties mentioned above lead to a longer life span for urethane products. A longer service life results in fewer downtimes for maintenance, yielding operational efficiencies and lower manufacturing costs – further making the case that polyurethane is superior to rubber – as well as metal and plastic.

About PSI Urethanes

Since 1966, through our own independent research and activity in the Polyurethane Manufacturers Association, PSI Urethanes has stayed on the leading edge of urethane technology – including developing advances in new materials, comprehensive designs, and processing technologies. Today we are among the most respected and trusted suppliers of custom urethane products.

We operate from our 45,000-square-foot manufacturing facility in Austin, Texas, which houses an extensive stock of polyurethane products. Our fully equipped manufacturing facility includes a versatile range of processing machinery, which allows us to work on unique, one-of-a-kind projects, as well as high volume components. Our in-house engineering, tooling, and custom mold shop, produces custom and stock production orders with exceptionally fast turn-around times. From conception to prototyping, to final production runs, our technical representatives and design engineers will work closely with your staff to meet your critical tolerances and specifications. You are guaranteed to receive experienced, professional, and personalized service from the first contact through your on-time delivery, with complete confidentiality and dedication to protecting your good name.

PSI Urethanes specializes in custom urethane products. Contact us today to see how we can help with your next manufacturing project, or give us a call at 1-800-888-5156.